Preparations

1.

Check that the switch (SF1) for the compatible heat

pump is in position “ ”.

2.

Check that the filling valves are fully closed (see

image).

Filling and venting

Caution

Insufficient venting can damage internal com-

ponents in NIBE FLM.

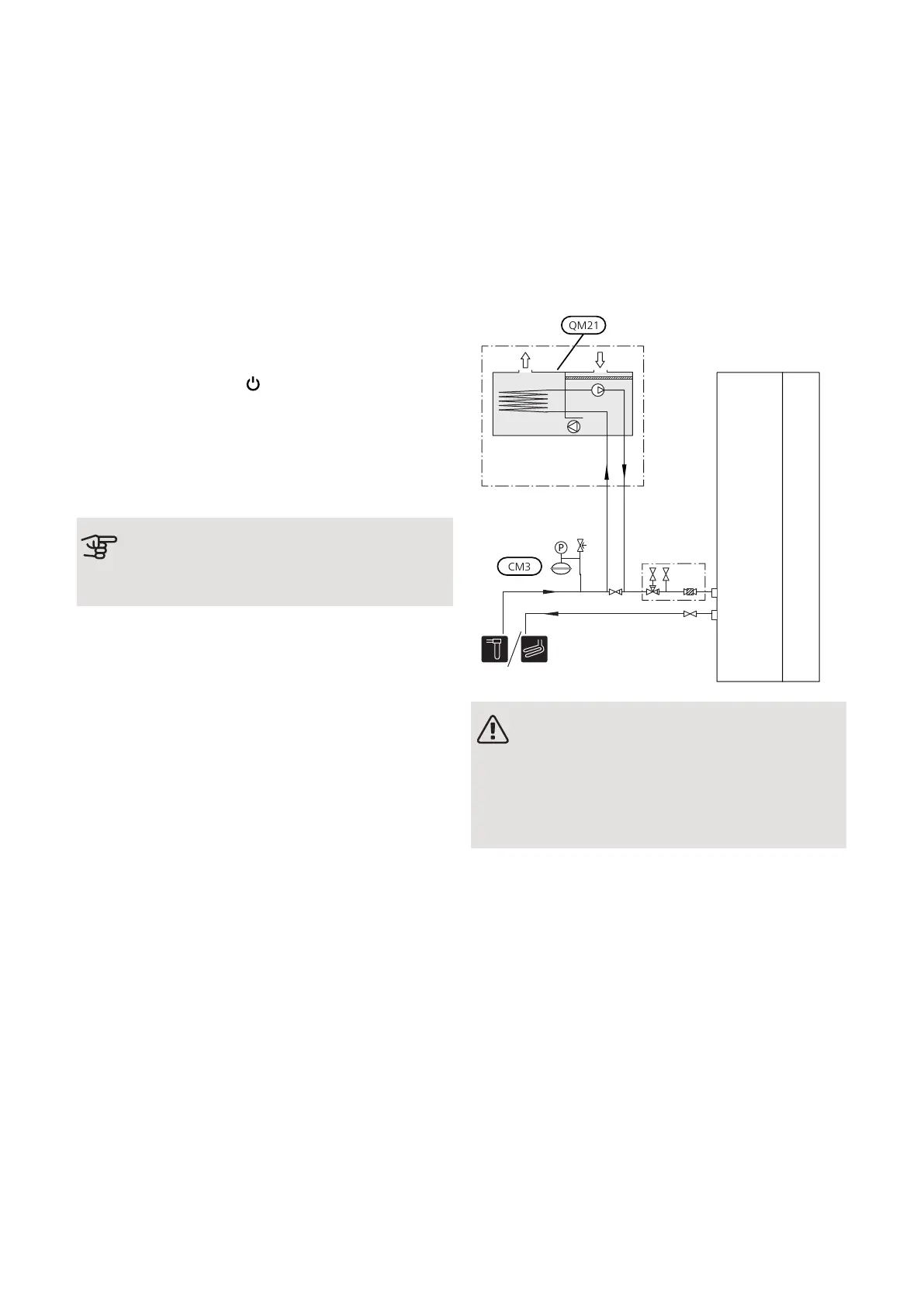

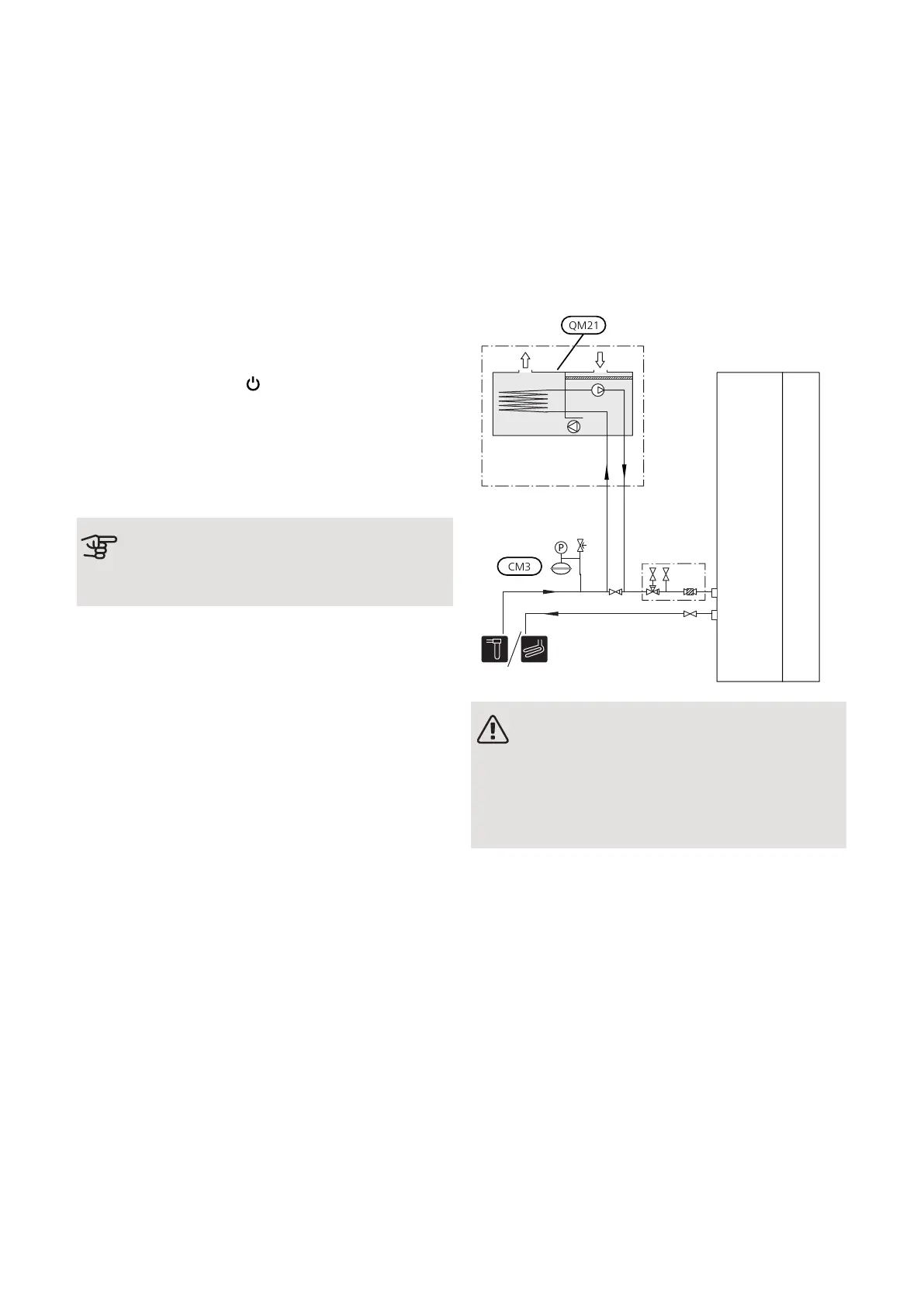

FILLING AND VENTING THE BRINE SYSTEM

When filling the brine system, mix the water with anti-

freeze in an open container. The mixture should be

protected against freezing down to about -15°C. The

brine is topped up by connecting a filling pump.

1.

Check that the level vessel is replaced with expan-

sion vessel (CM3).

2.

Check the brine system for leakage.

3.

Connect the filling pump and return line on the brine

system’s filling connection (QZ20) (accessory).

4.

Close the reversing valve in the filling connection

(QZ20).

5.

Open the valves on the filling connection (QZ20).

6.

Start the filling pump.

7.

Fill until liquid enters the return pipe.

8.

Vent the brine system with vent valve (QM21) on

NIBE FLM.

9.

Close the valves on the filling connection (QZ20).

10.

Open the reversing valve in the filling connection

(QZ20).

NOTE

Venting may be necessary during installation

and after a period of use. Venting takes place

through vent valve (QM21). When venting, set

the switch for the circulation pump (SF2) to

position “0”.

NIBE FLMChapter 6 | Commissioning and adjusting22

6 Commissioning and adjusting

Loading...

Loading...