10

6 - WIRING AND CONNECTIONS

Table 1 - MAXIMUM RUN (FT) PER WIRE GAUGE

110V AWG 14 12 10 8 6 4

MAX RUN (ft) 180 280 460 700 1150 1800

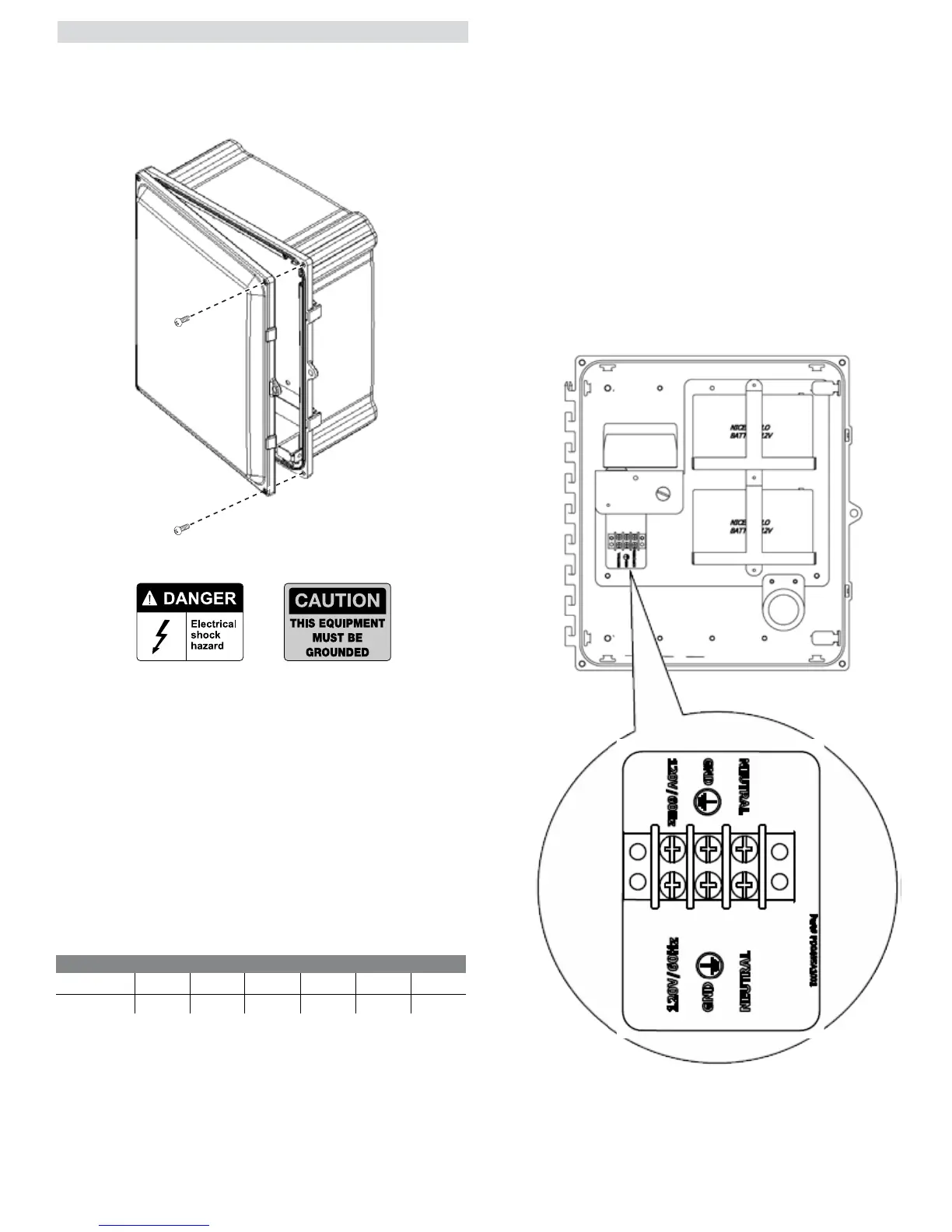

120VAC Input connection

ISOLATE ALL ELECTRICITY PRIOR TO INSTALLATION OR SERVICE

• Disconnect power to the gate operator by manually opening its dedicated

circuit breaker before making any mechanical or electrical adjustments.

• Use a 20 Amp dedicated circuit breaker for each installed gate operator.

• Open dedicated circuit breaker supplying power to this gate operator

BEFORE a new installation or making any modications to an existing

installation of this gate operator.

• All wiring connections MUST be made by a qualied individual.

• Run individual circuits in separate U.L. listed conduits. Do not combine

high voltage (120VAC) power wiring and low voltage (+12VDC to +24VDC)

control wiring in the same conduits.

• Use the information in table 1 to determine high voltage wire size

requirements. The distance shown in the chart is measured in feet from the

operator to the power source. If power wiring is greater than the maximum

distance shown, it is recommended that a service feeder be installed. When

large gauge wire is used, a separate junction box must be installed for the

operator connection. The wire table is based on stranded copper wire. Wire

run calculations are based on a 110 VAC power source with a 3% voltage

drop on the power line, plus an additional 10% reduction in distance to

allow for other losses in the system.

This gate operator system should be grounded through the earth ground in the

AC mains wiring system (GREEN WIRE).

PROPER EARTH GROUND CONNECTION REQUIRED FOR ALL

INSTALLATIONS!

Use the connection shown for connecting 120VAC power to this system.

WARNING: External entrapment protection must be added to insure a

safe vehicular gate operating system.

This swing gate operator uses an inherent entrapment sensing system as well

as external type sensors.

Entrapment protection must be provided by a combination of non contact

inherent devices. Disconnect power to the gate operator before installing the

non contact sensors.

Actual placement of sensors is dependent on the specic installation

requirements.

One or more non contact sensors should be located where the risk of

entrapment or obstruction exists such as the perimeter reachable by a moving

gate or barrier.

Use only U.L. listed (or equivalent) non contact sensors. Inputs from the photo

beam to the circuit board are Normally Open (N.O.). Use only U.L. listed (or

equivalent) non contact sensors.

Connect the non contact sensors. Inputs from the photo beam to the circuit

board are Normally Open (N.O.). Photo beam input shall REVERSE travel of

gate when activated during the CLOSE CYCLE ONLY. Gate will resume normal

operation when photo-beam is no longer activated. To reduce the risk of

SEVERE INJURY or DEATH:

Remove the screws from the cover and open the door. Place the screws in

a safe location until the installation is complete. Once complete, replace the

screws in the cover door.

NOTE: These screws must be replaced to ensure security for the

system and to ensure an adequate seal of the cover.

Loading...

Loading...