31Service Manual – SC900 24 - Electrical System

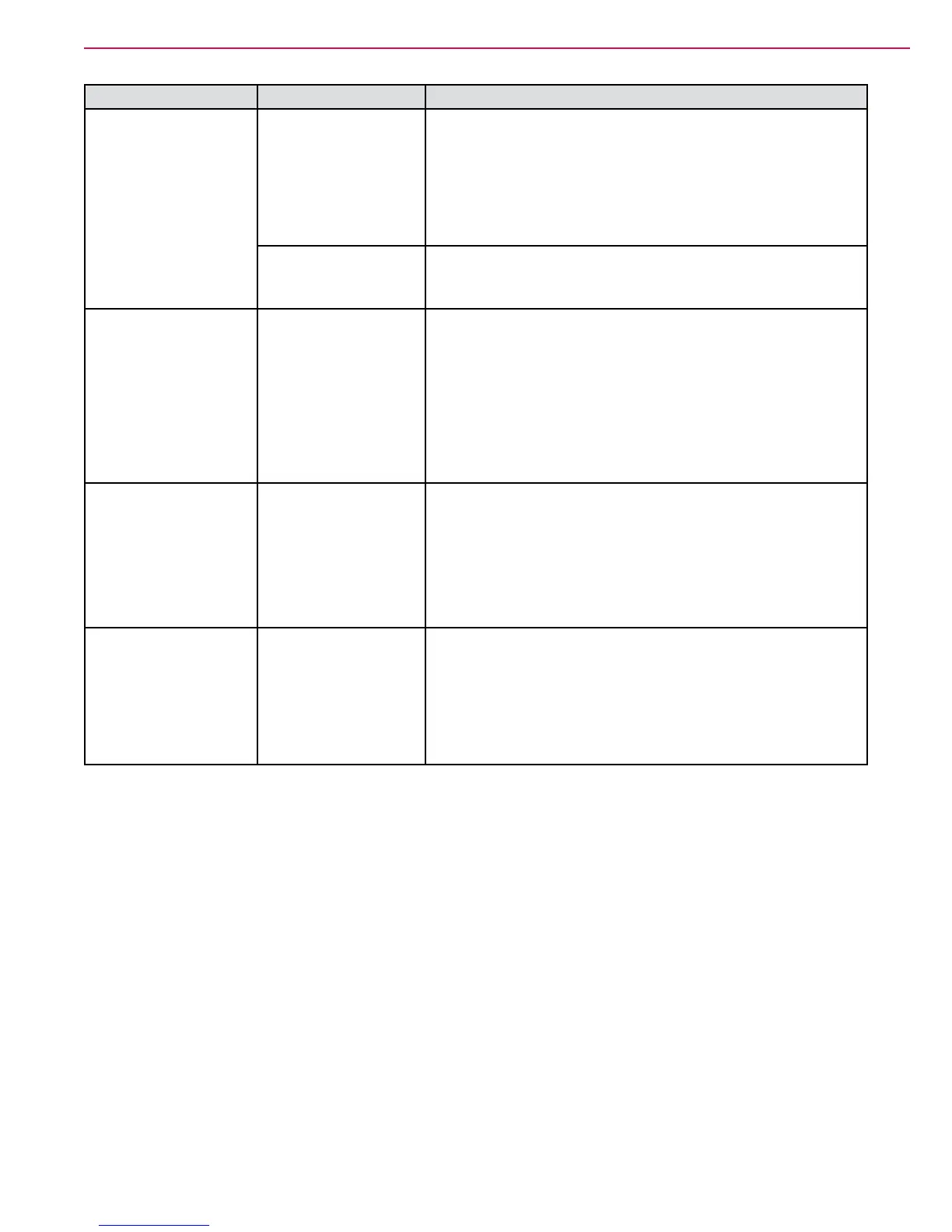

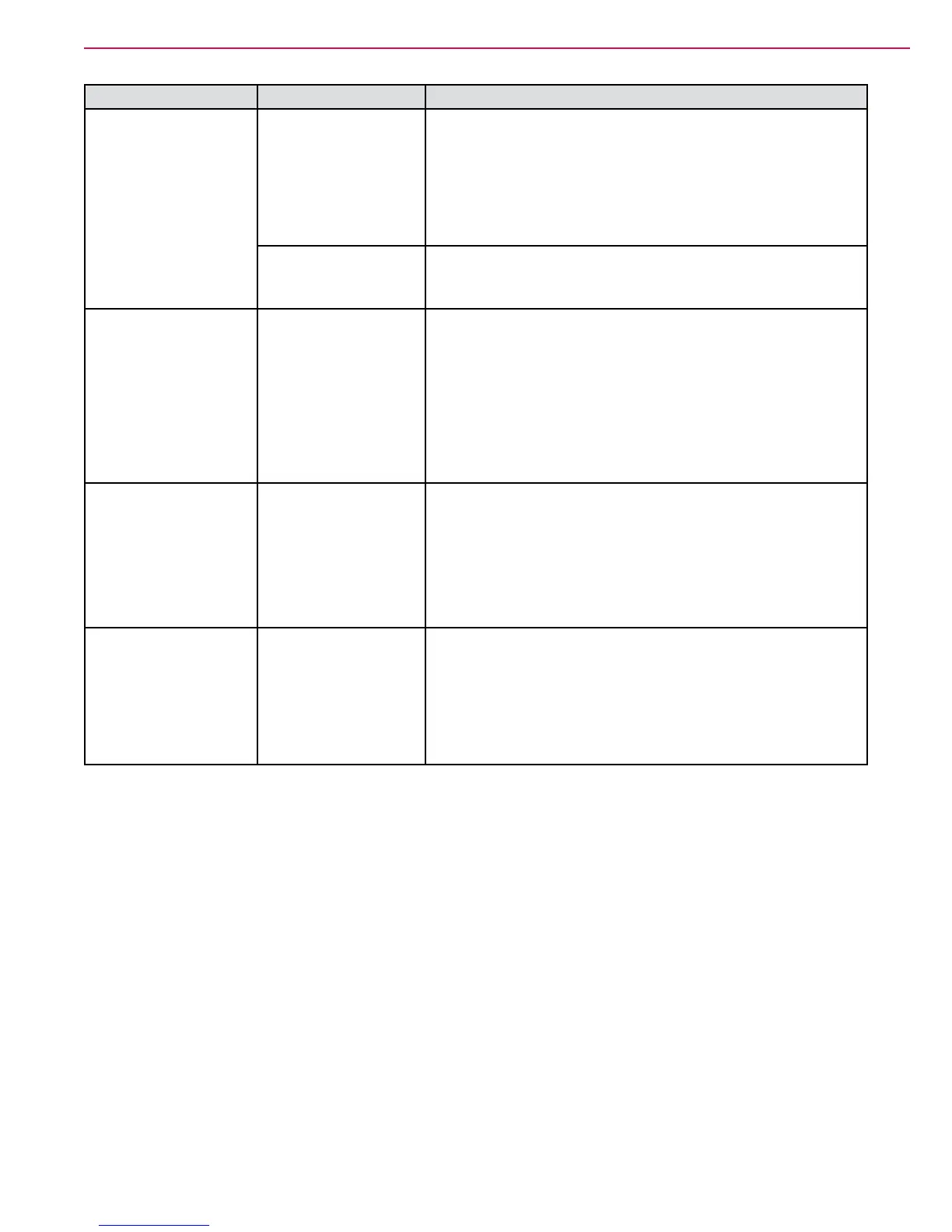

Problem Cause Notes & Correction

No Scrub system, but

drive and vacuum

operational.

• No Brush

• No Solution

• No Detergent

• Drive active

• Vacuum active

K1 circuit fault The K1 circuit controls all of the scrub functions, and is related

to the low-voltage cutout feature, which is controlled by the

hour meter.

• Check the K1 relay:

− If the relay is open, either the relay is faulty, or the hour

meter is faulty.

− If the relay is closed, then the brush switch is faulty.

Hour Meter Failure If the hour meter does not provide “ground” to the K1 relay, it

will disable all scrub functions as though the battery voltage is

too low for operation

No Solution, but brush

motors run

Solution circuit or

optional module

The solution solenoid and optional detergent pump are

enabled only when the brush is active.

• For all models, make sure that the solution shutoff valve is

not closed.

• For non-EcoFlex models, make sure the shunt jumper

below the solution lever is in place. If so, then check the

solenoid.

• For EcoFlex models, if both solution and detergent

solenoids are non-functional, the module is likely faulty.

No Brush function, but

solutionows

Brush circuit failure Becausesolutionisowing,youcaneliminatetheK1andS4

circuits as a cause.

• If both brush motors are off, then the most likely cause is

the K2 power relay.

• Ifonlyonemotorhasfailed,rstcheckitscircuitbreaker,

and then check the motor. Swap the two motor connectors

to isolate whether it is before or after the connector.

No vacuum, but all

other systems function

Vacuum circuit If any other systems are running, then you know the KSI

circuit is functional. This leaves solely the vacuum circuit itself

as the cause.

• Check the vacuum switch at the squeegee lever

• Check the vacuum relay (K3)

• Check the vacuum breaker (CB4)

• Check the motor

Battery Testing

A battery problem is usually recognized by the machine operator as a decrease in the machine’s running

time. This condition is usually caused by one or more “dead cells” in the battery system.

There are 2 ways to nd a dead cell:

• Use a hydrometer to check the specic gravity (or “state of charge”) of the uid in each cell. A dead cell is

one that reads 50 points (or more) lower than the other cells.

• Use a volt meter to check the voltage of each battery. Look for a battery with a voltage that is 1 or 2 volts

less than the other batteries. Check under the following conditions:

– With the batteries fully charged,

– With the scrub and drive motors running,

– With the batteries discharged, but still above the voltage cutoff threshold.

If the batteries in the machine are more than 1 year old, it’s usually best to replace the whole set, rather

than replacing just one battery.

Loading...

Loading...