43Service Manual – SC900

30 - Solution System

Functional Description

The SC900 machine has a 29.5-gallon (112 liter) solution tank incorporated into the main body of the

machine. A clear tube on the right side of the machine below the ll cap serves as a water level indicator

for the tank. At the outlet of the solution tank, under the machine, is a manual shutoff valve followed by a

serviceable solution lter that prevents debris from entering the rest of the solution system.

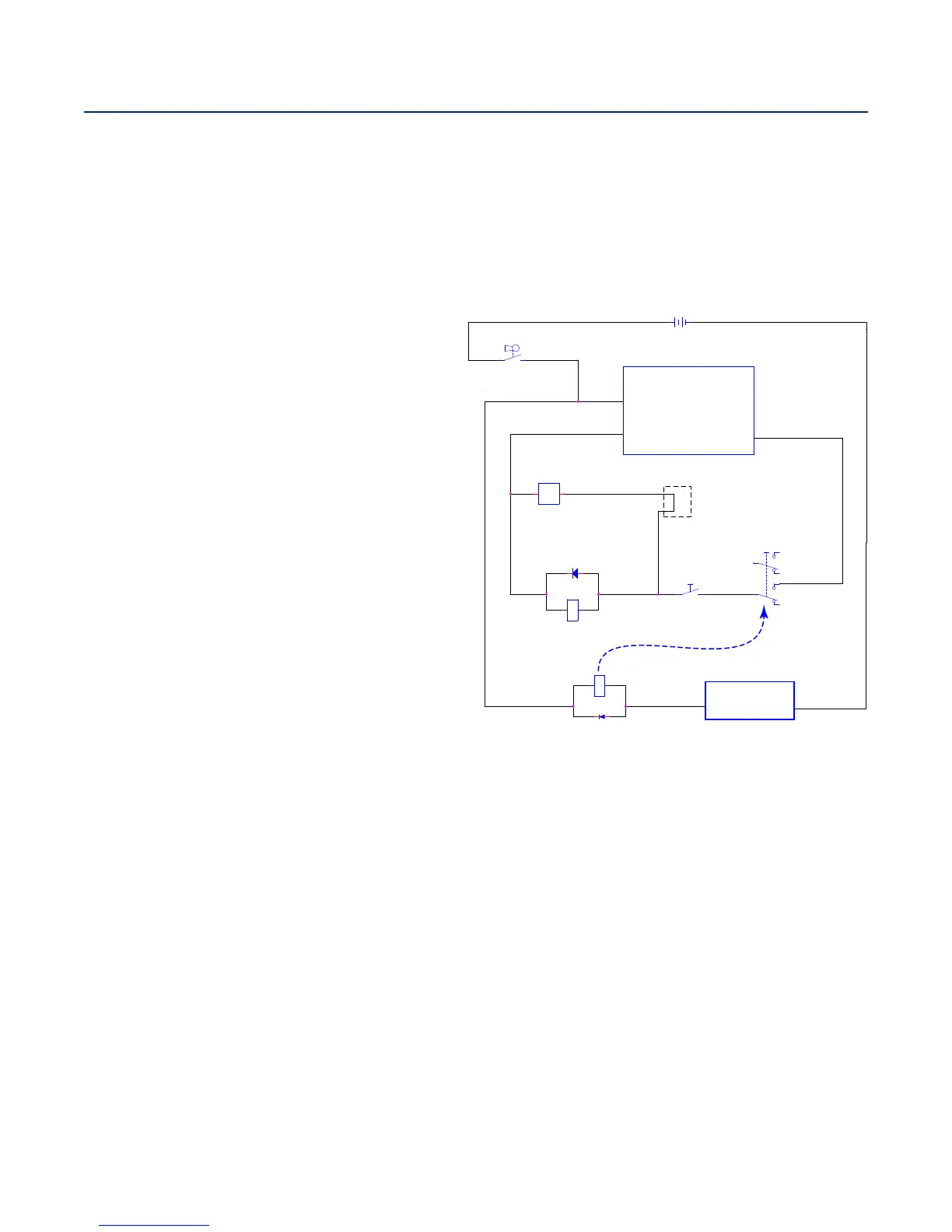

Non-Detergent Models

All machines use gravity feed and a solution

solenoid to provide solution to the scrub deck. For

non-detergent machines, the ow rate of solution

is controlled mechanically with a cable connected

between the solution lever, down to the solution

shutoff valve. The solution solenoid is either all-

on or all-off, and is controlled by the same circuit

that activates the brush motors. A circuit jumper

replaces the connector where the optional EcoFlex

control board connects in the solution panel.

For the solution circuit to be active, the machine

must be in motion, and the scrub brushes be active.

When the machine is in motion, the Curtis drive

controller makes the Brake- output equal to battery

negative. This passes through the K1 relay, through

the brush switch (foot lever), through the jumper

(non-EcoFlex), and energizes the solution solenoid.

The solution solenoid receives 36-volt, non-PWM

(Pulse Width Modulated) power, to be either all-on

or all-off.

BLK

PNK/WHTVIO

VIO/WHT

PNK/BLU

VIO/GRN

VIO

PNK

PNK

S1

SW, SPST KEY

S4

SW, BRUSH

RELAY, LVC

1

2

3

4

5

6

CURTIS 1228

KSI

5

BRAKE-

6

BRAKE+

14

D2

K1 RELAY, LVC

BATTERY GAUGE WITH HOURMETER

FET DRAIN

3

B-

4

L1

COIL, SOLENOID

1 2

D1

36 VDC

+ -

K2

COIL, BRUSH

K1

JUMPER

Loading...

Loading...