62Service Manual – SC900 34 - Scrub System, Cylindrical

One Brush Not Working

If only one brush is not working, you know it is not related to the drive controller, nor the power relay (K2).

The problem is isolated between the 25 amp circuit breaker and the motor.

• Swap the two motor connectors at the scrub deck. If the same motor is inoperable, you know its the motor.

If the other motor becomes inoperable, you know it is in the wiring or the circuit breaker.

• If the problem is at the motor, inspect/replace the motor brushes. If the brushes are not worn, replace the

motor.

Both Brush Motors Not Working

• If solution ows, you can eliminate the drive

controller and K1 relay as a possible cause.

Troubleshoot the K2 relay.

– Activate the scrub system as described on

page 61.

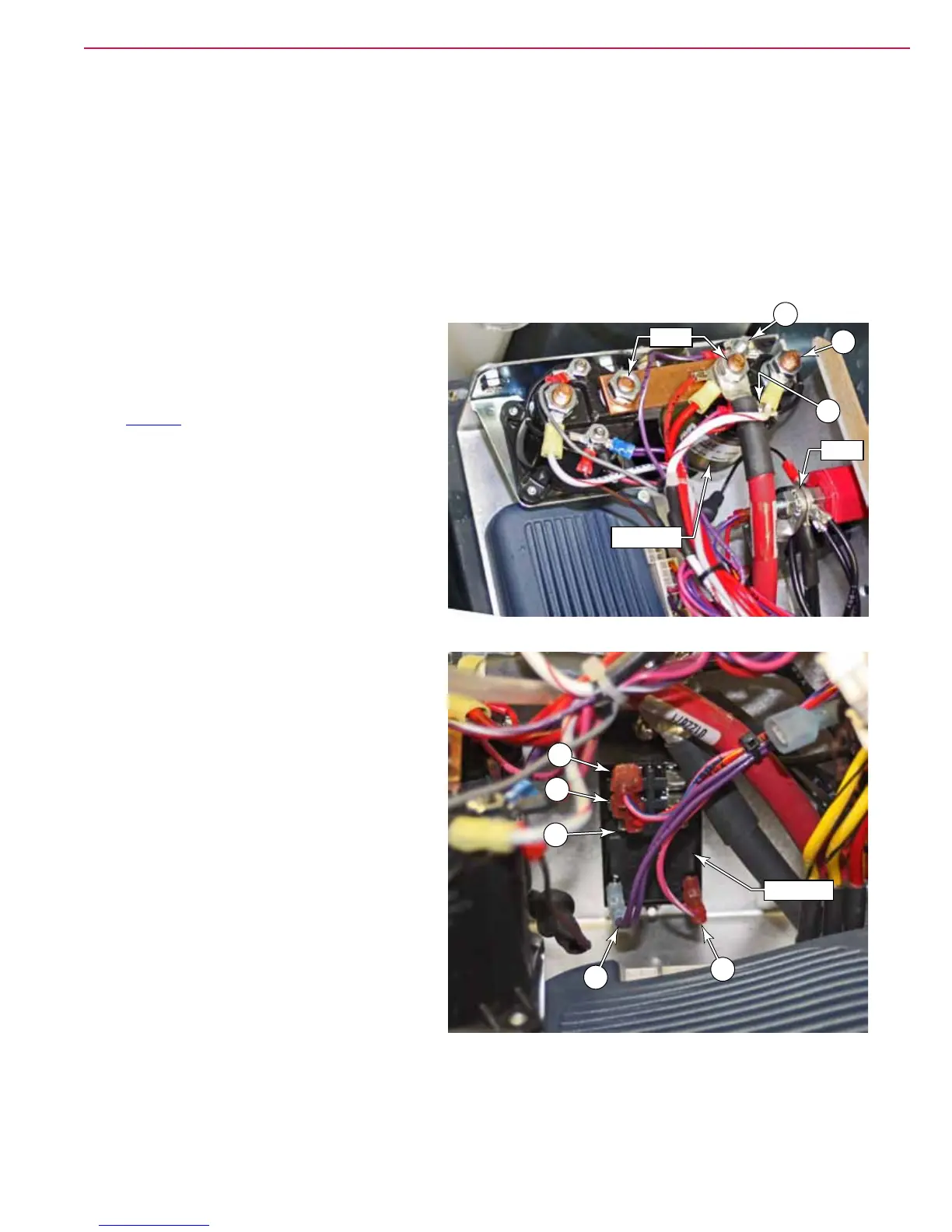

– Check the voltage from (A) to (Batt-). If

it’s 36V, then the problem lies between the

relay and the circuit breakers, or a broken

ground at the (Batt-) lug.

– Check the voltage across the coil from (B)

to (C). If the voltage is 36V, then the relay

is defective. If the voltage is zero, trace the

Pink and Violet wires to locate a break.

• If neither solution nor optional detergent

ows, check the following:

– Check the continuity of the brush (deck

lower) switch.

– Check the function of the K1 relay.

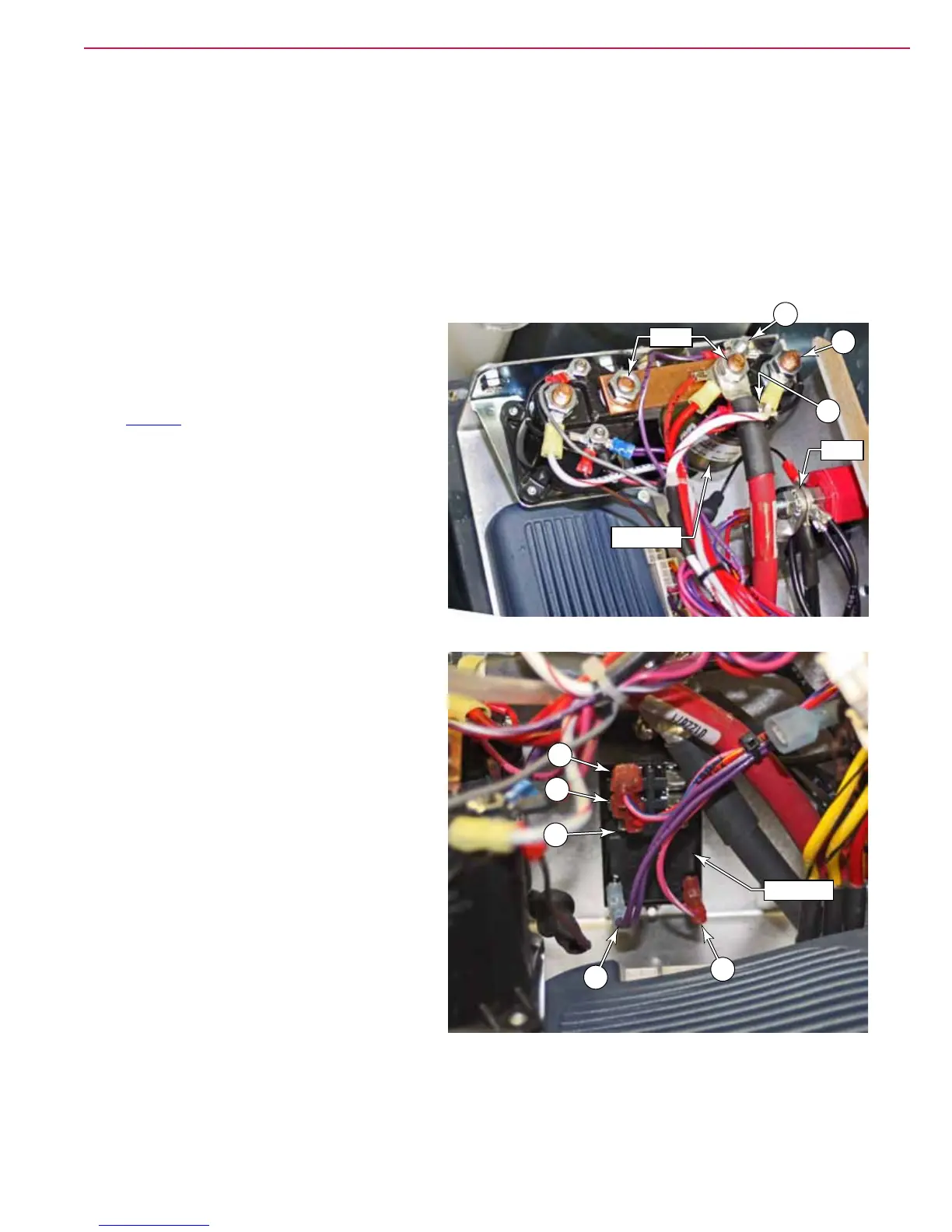

◦ Move the Pink/Blue wire from the top

(A) terminal to the lower (C) terminal.

If the brush motors run, you can

eliminate the Drive Controller as a

cause, but you know that the relay is

not closing. (Make sure to move the wire

back.)

◦ If the brush motors did not run in the

previous step, the drive controller is the

most likely cause.

◦ If the brush motors ran in the previous

step, check the voltage between (D) and

(E). If 36 volts is present, then the relay

is faulty.

◦ If 36 volts was not present in the previous step, then it is likely that the hour meter is faulty.

B

Batt+

Batt-

A

C

K2 Relay

A

K1 Relay

B

C

D

E

Loading...

Loading...