ENGLISH INSTRUCTIONS FOR USE

28 SW4000, FLOORTEC R 870 - 1464815000

03/2013

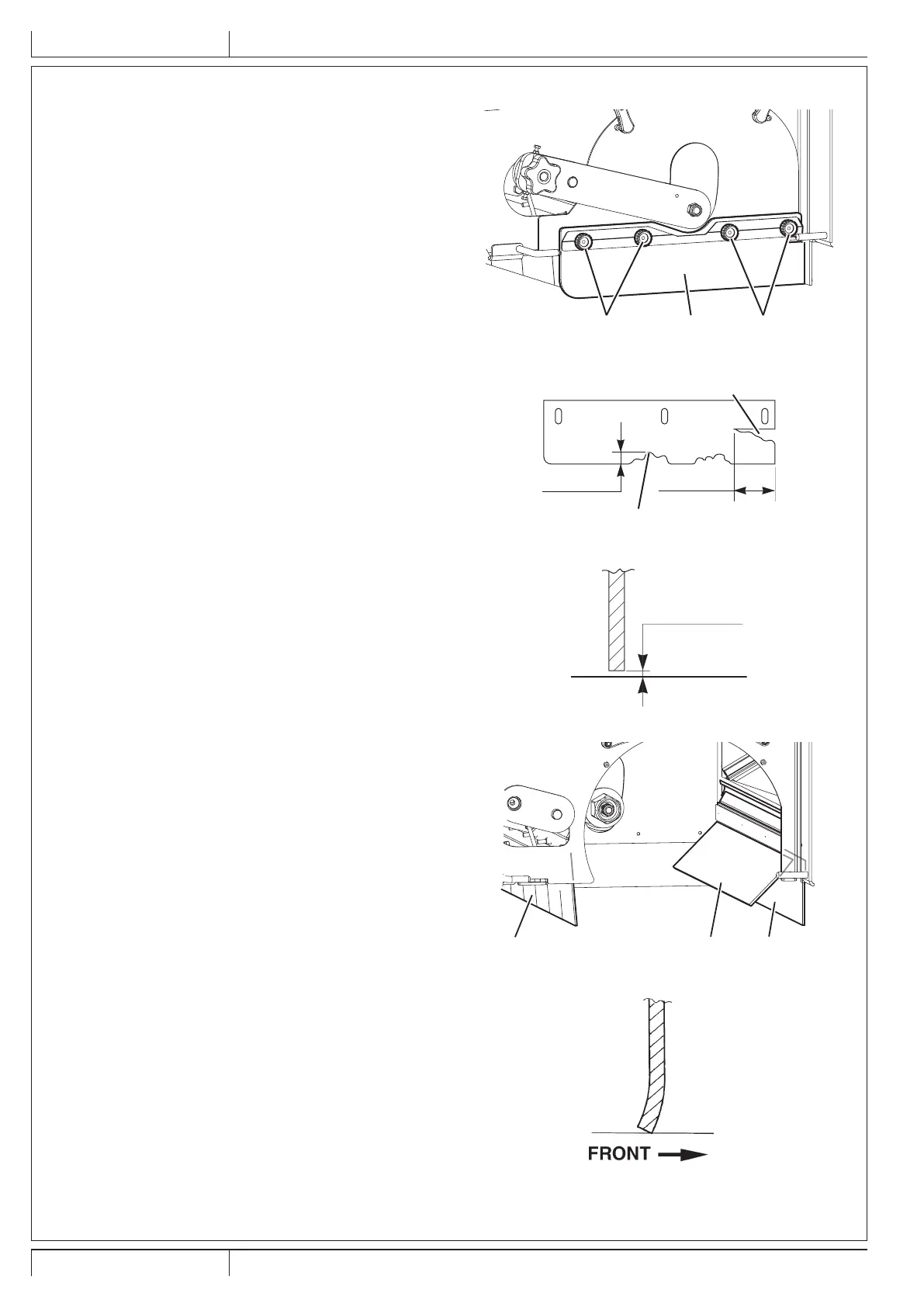

SKIRT HEIGHT AND OPERATION CHECK

Preliminary Operations

1. Empty the hopper (as shown in Use chapter), because the

weight of the waste inside the hopper can affect the skirt

height check.

2. Drive the machine on a level ground that is suitable for

checking the skirt height.

3. Turn the ignition key (61) to “0” and engage the parking

brake.

Side Skirt Check

4. Remove the left and right doors (13 and 12) by turning the

fasteners.

5. Check the side skirts (A, Fig. 14) for integrity.

Replace the skirts when they have cuts (C, Fig. 15) larger

than 20 mm or cracks/tears (D) larger than 10 mm (for skirt

replacement, refer to the Service Manual).

6. Check that the distance from the oor of the side skirts (A,

Fig. 14) is within 0 - 3 mm (Fig. 16).

If necessary, loosen the knobs (B, Fig. 13) and adjust the

skirt position. Then tighten the knobs (B).

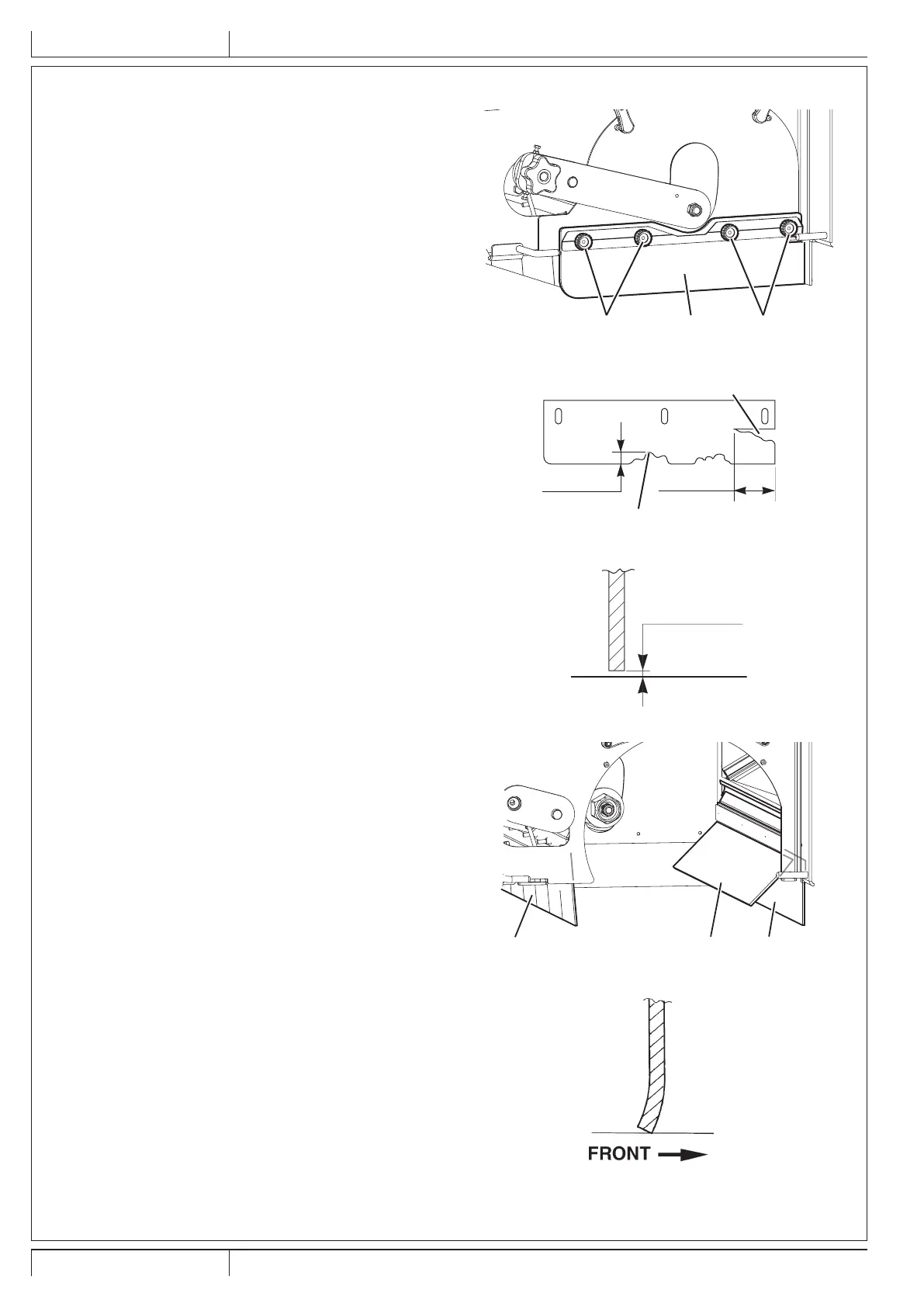

Front and Rear Skirt Check

7. Remove the main broom as shown in the relevant

paragraph.

8. Check the front skirt (E, Fig. 17) and rear skirts (F) and (G)

for integrity.

Replace the skirts when they have cuts (C, Fig. 15) larger

than 20 mm or cracks/tears (D) larger than 10 mm.

9. Check that the front (E, Fig. 17) and rear skirt (G) slightly

rub ground without being detached from it (Fig. 18).

10. For the skirt replacement, see the Service Manual.

Reassembly

11. Assemble the components in the reverse order of

disassembly.

P100602

Figure 14

> 20 mm

(> 0,8 in)

> 10 mm

(> 0,4 in)

P100603

Figure 15

0÷3 mm

(0÷0,12 in)

P100604

Figure 16

P100605

Figure 17

P100606

Figure 18

Loading...

Loading...