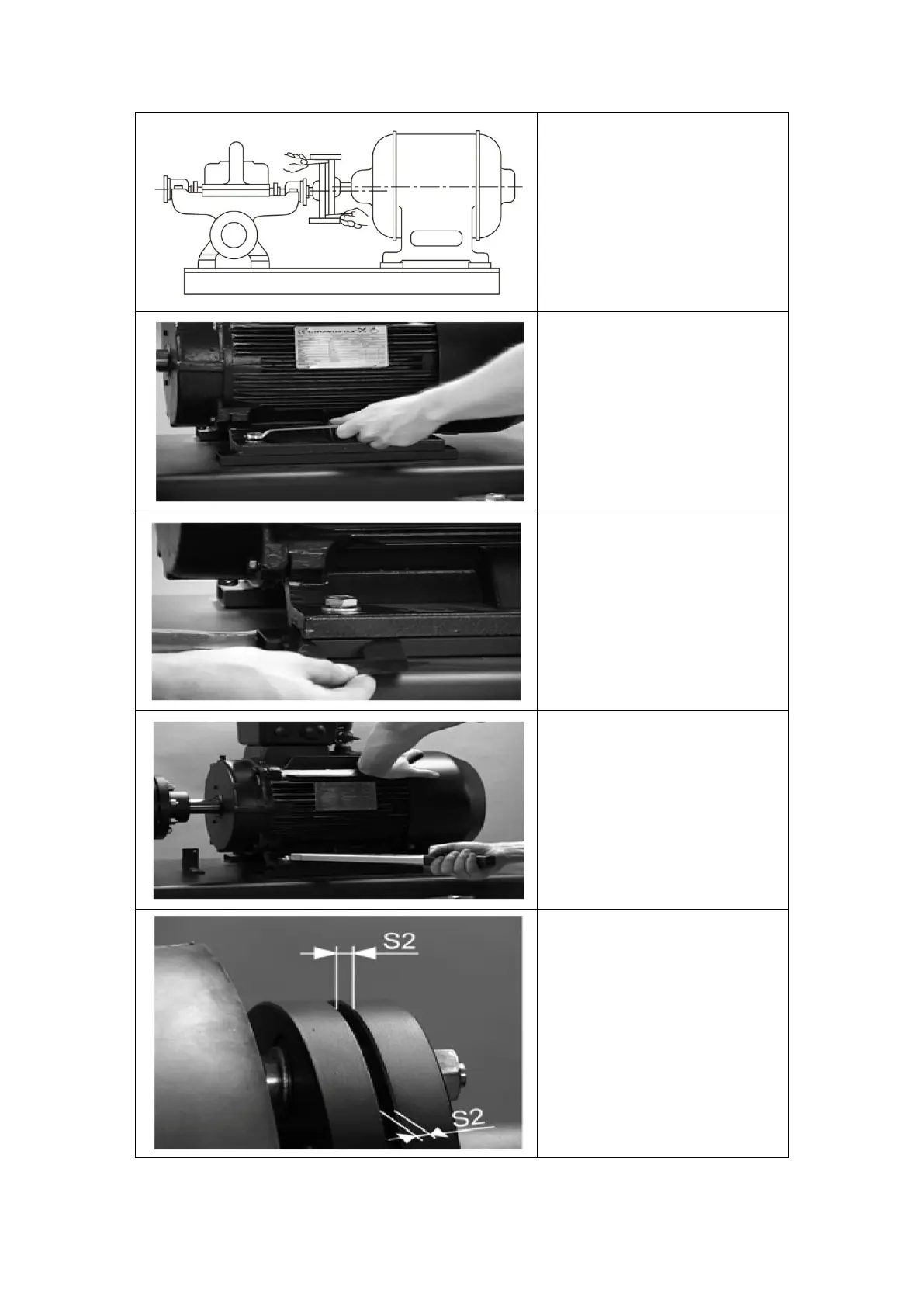

5. Adjust the position of the

motor,Loosen the base

screw holding the motor.

6. Fill the gap sheet with

suitable thickness.

7. Again tighten the base

screw to the correct torque.

Back to Step 3, re-check the

alignment.

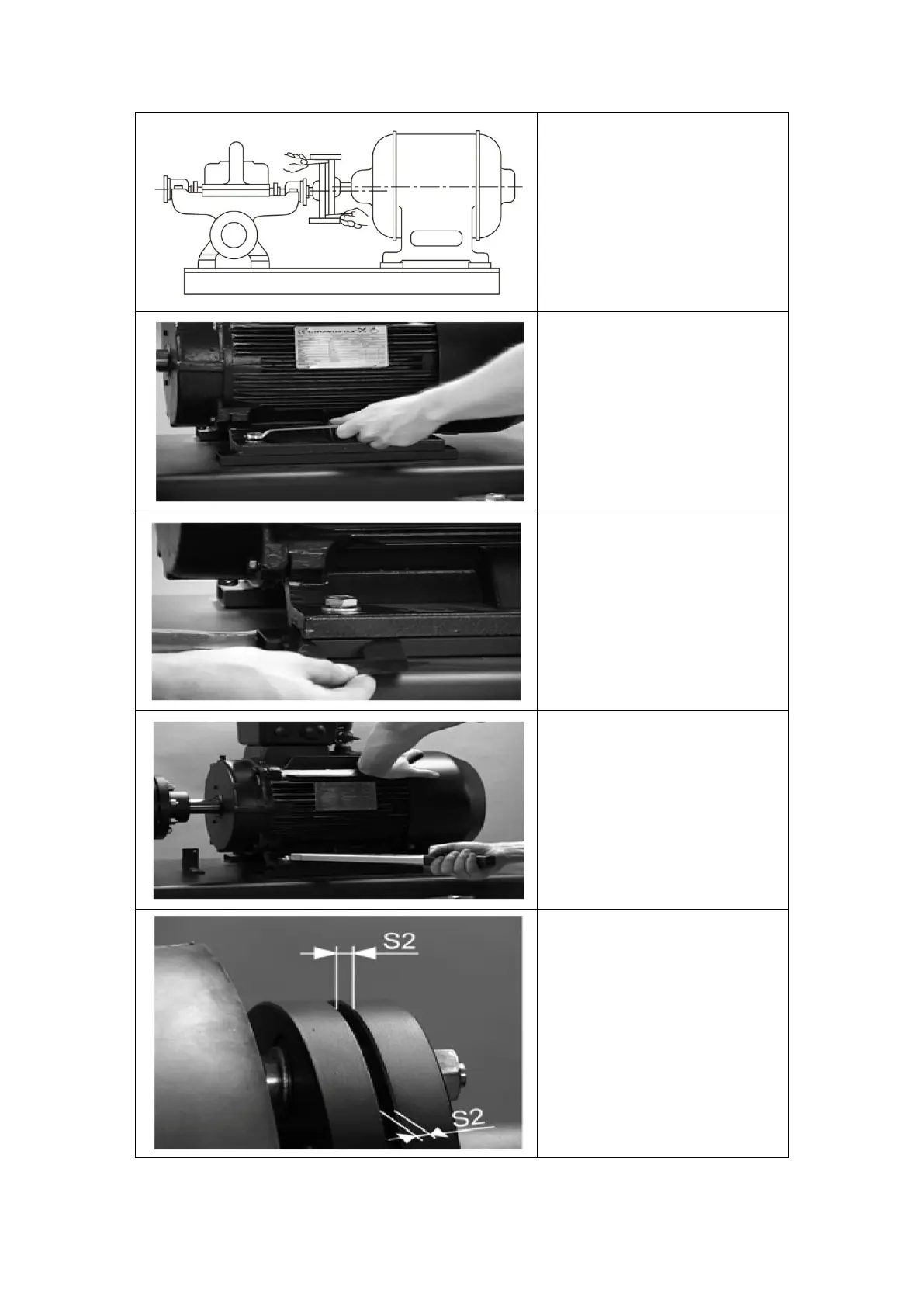

8. Measure S2: check the S2

distance of the entire

circumference of the

coupling.

If the S2 value is within the

allowable error range, the

alignment over. If the

allowable error is exceeded,

go back to step 5.

Note: S2 is the diaphragm thickness plus the allowable clearance. It is recommended that

Loading...

Loading...