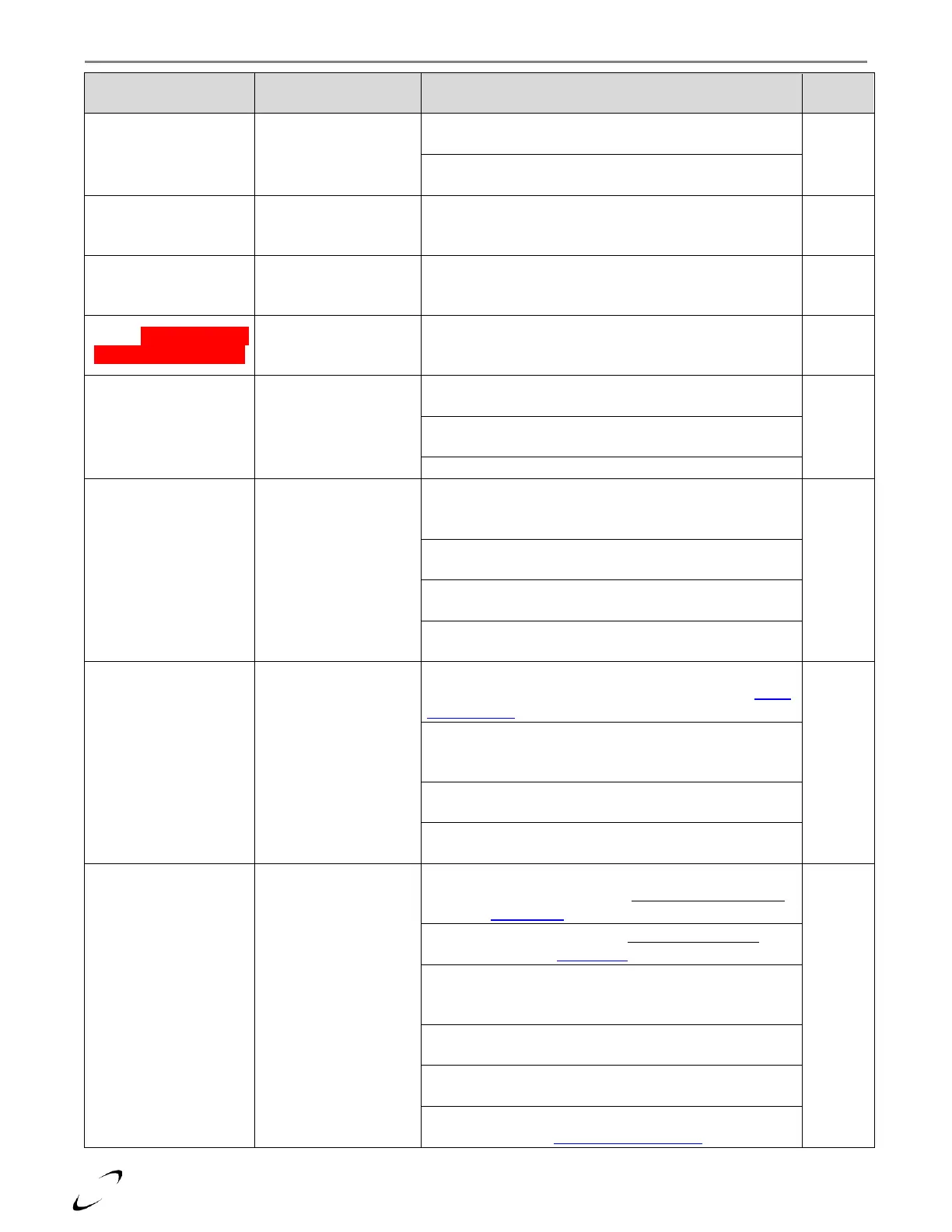

Installation and Operation Manual TFTN 085-199

150 – Common flow

sensor overheat

System sensor reading >

210°F

Faulty wiring – check the wiring to the System sensor for

water or corrosion

Faulty sensor – check for proper readings from the System

sensor (see Table 18-2).

1P1 1 – Flow check failed

(Supply Temp Change

Fast)

Outlet T-rise >

12.6°F/sec

Normal operation – In systems with high and low

temperature zones this message may be appear serval

times as zones turn off and on.

1P2 1 – Flow check failed

(Sensor Delta T Too

High)

Normal operation – In systems with high and low

temperature zones this message may be appear serval

times as zones turn off and on.

1P3 1 – Flow check failed

(Supply Temp Too High)

Inlet > Outlet temp by

18°F

Normal operation – In systems with high and low

temperature zones this message may be appear serval

times as zones turn off and on.

Water pressure reading

< 7 psi

Low water pressure – raise the water pressure to a

minimum of 12 psi

Faulty wiring – ensure the wire harness is connected to

the water pressure sensor. Check for broken wires

Faulty sensor – replace pressure sensor

DHW tank sensor

reading is invalid

Incorrect setting – DHW Mode is set as “Tank Sensor”, but

a tank sensor is not being used. Change DHW Mode

setting to “Aquastat”

Tank sensor not connected – Connect IWH tank sensor to

DHW SWITCH/NTC

Faulty wiring – check the wiring to the Tank sensor for

water or corrosion

Faulty sensor – check for proper readings from the Tank

sensor (see Table 18-2).

209 – Storage tank

overheat

Plumbing problem – Boiler water is circulating through

the IWH coil during CH serving – correct piping; see Boiler

System Piping section

Tank sensor improperly installed – ensure the tank sensor

is fully inserted into the well of the tank in the proper

location.

Faulty wiring – check the wiring to the Tank sensor for

water or corrosion

Faulty sensor – check for proper readings from the Tank

sensor (see Table 18-2).

2P2 – Anti-legionella

function not finished

Anti-legionella function

is not complete (to

reset, switch the power

to the boiler off/on)

Anti-legionella Function turned on – if the anti-legionella

function is not wanted, then set Anti-Legionella Function

= Off (see DHW Setup)

Boiler setting to low – set DHW Modulation Setpoint =

180°F or higher (see User Menu)

Tank sensor improperly installed – ensure the tank sensor

is fully inserted into the well of the tank in the proper

location.

Faulty wiring – check the wiring to the Tank sensor for

water or corrosion

Faulty sensor – check for proper readings from the Tank

sensor (see Table 18-2).

Plumbing problem – verify that boiler water is circulating

to the IWH coil; see Boiler System Plumbing section

Loading...

Loading...