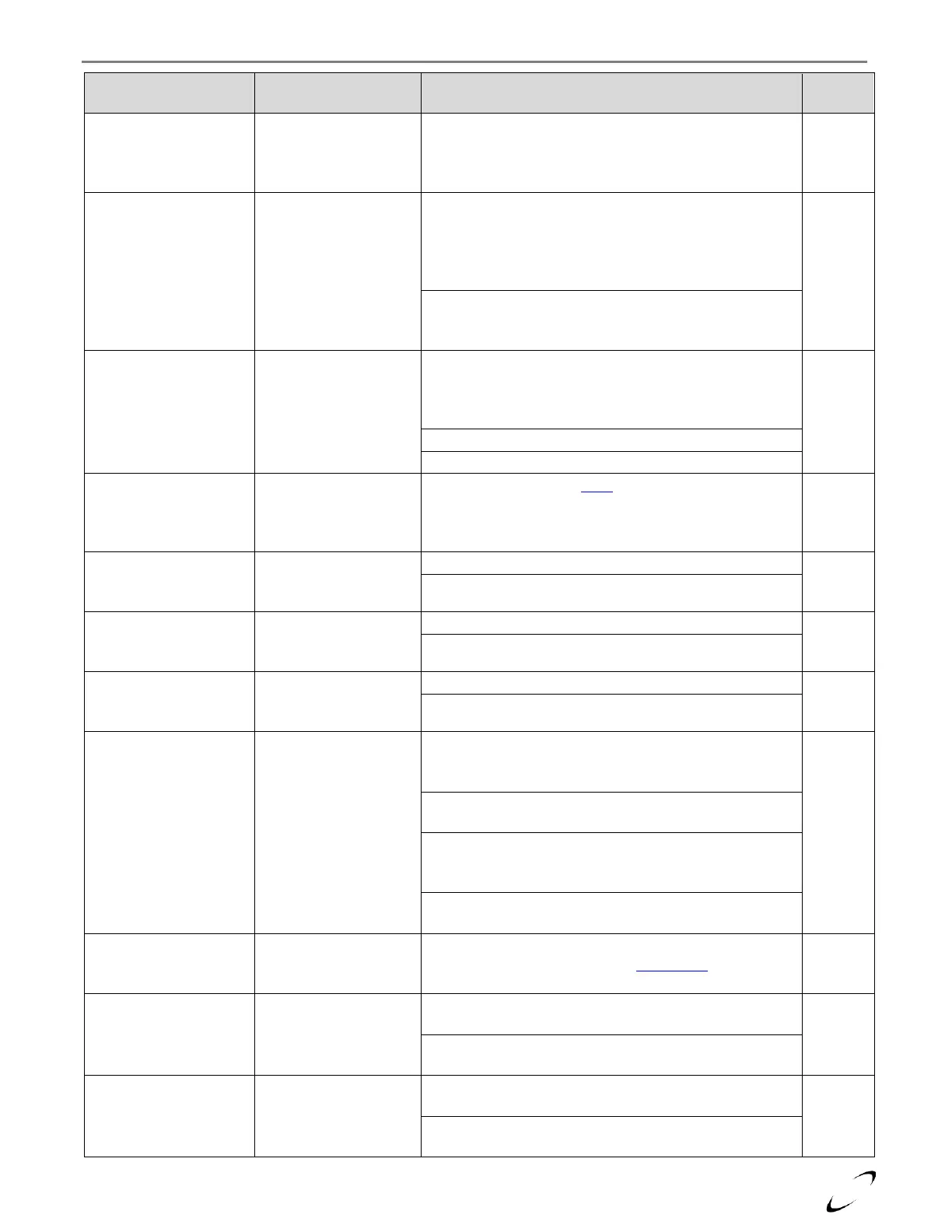

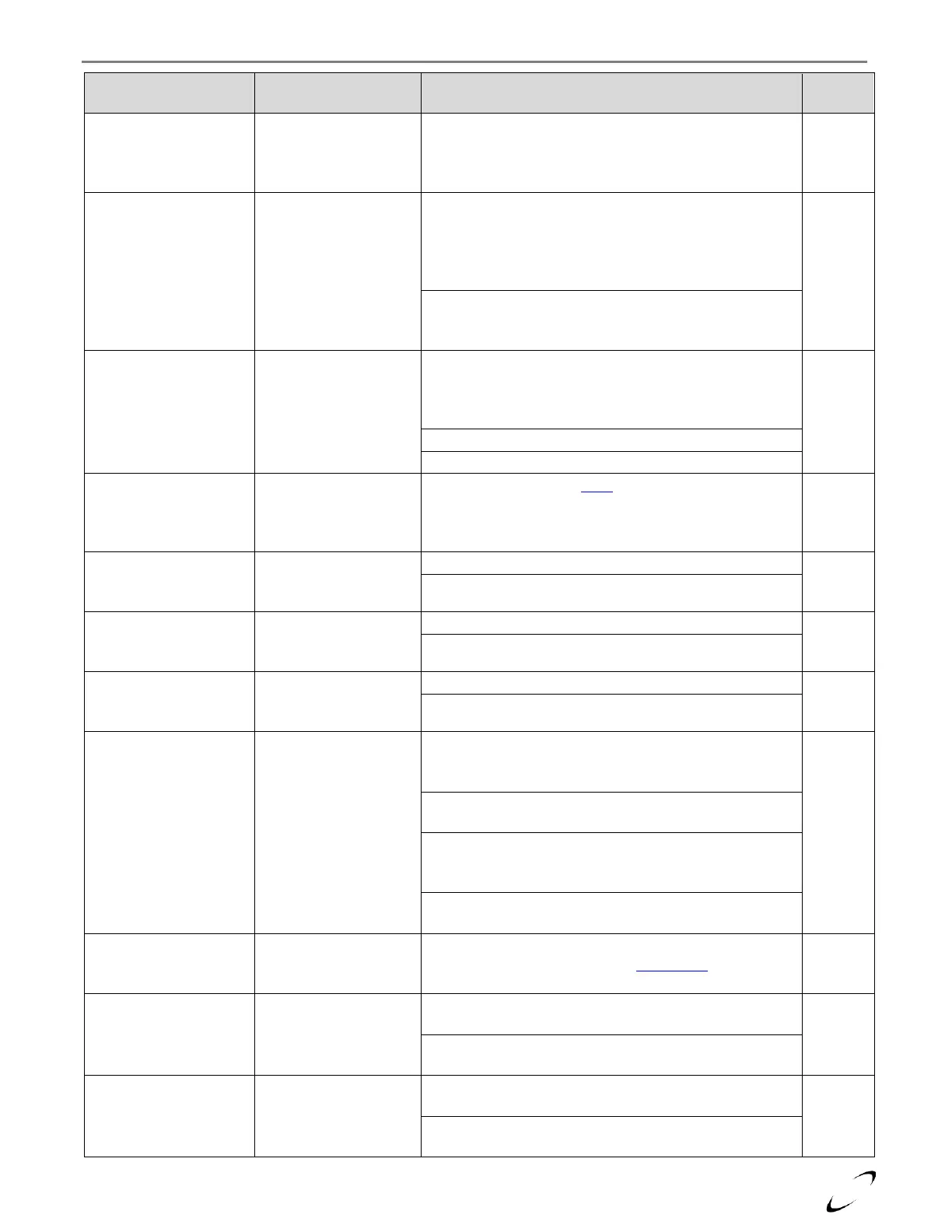

TFTN 085-199 Installation and Operation Manual

301 – Display error

Eeprom

Power problem /

defective PCB

1.Test for proper voltage and grounding.

2.Switch the boiler OFF and ON at the main electrical

power supply. If the problem happens again replace the

main PCB

302 – Communication

error GP - GIU

Wiring between display and PCB issue:

1. Test for proper voltage and grounding.

2. Switch the boiler OFF and ON at the main electrical

power supply. If the problem happens again replace

the main PCB

Power problem – Check the wire connection between the

PCB and the display for damage, corrosion or other

problems.

PCB internal error (to

reset, switch the power

to the boiler off/on)

Water pressure sensor wiring damaged or shorted:

1. Check the water pressure switch wiring for damage or

shorts

2. Test for proper voltage and grounding.

Power problem – test for proper voltage and grounding.

Faulty PCB – if the problem persists, replace the PCB

> 5 resets in 15 minutes

(to reset, switch the

power to the boiler

off/on)

Check error history (see Error section) and correct the

source of the respective fault codes.

PCB internal error (to

reset, switch the power

to the boiler off/on)

Power problem – test for proper voltage and grounding.

Faulty PCB – if the problem persists, replace the PCB

PCB internal error (to

reset, switch the power

to the boiler off/on)

Power problem – test for proper voltage and grounding.

Faulty PCB – if the problem persists, replace the PCB

PCB internal error (to

reset, switch the power

to the boiler off/on)

Power problem – test for proper voltage and grounding.

Faulty PCB – if the problem persists, replace the PCB

309 – flame detection

while burner is off

Damaged flame sensor or flame sensor wire – check flame

sensor and flame sensor wire for damage, replace flame

sensor

Water damage – check flame sensor and PCB for water

damage or corrosion

Flooded combustion chamber – If the condensate drain

was blocked and the chamber flooded, dry the chamber

and flame sensor

PCB internal fault – If the Flame sensor wire is good and

the flame sensor has been replaced, replace the PCB

3P9 – Sched.

Maintenance-Call for

Service

Months to next

maintenance time has

elapsed

Service the boiler and select RESET from the Setup ->

Diagnostics -> Service menu; see Diagnostics section.

411 – Room sensor

circuit open or short

circuit Zone 1

Room sensor circuit

open or short circuit

Zone 1

BUS wiring damaged – Inspect BUS wiring for bad

connections

Damaged PCB – If nothing is wired to the BUS

connections, replace the PCB.

412 – Room sensor

circuit open or short

circuit Zone 2

Room sensor circuit

open or short circuit

Zone 2

BUS wiring damaged – Inspect BUS wiring for bad

connections

Damaged PCB – If nothing is wired to the BUS

connections, replace the PCB.

Loading...

Loading...