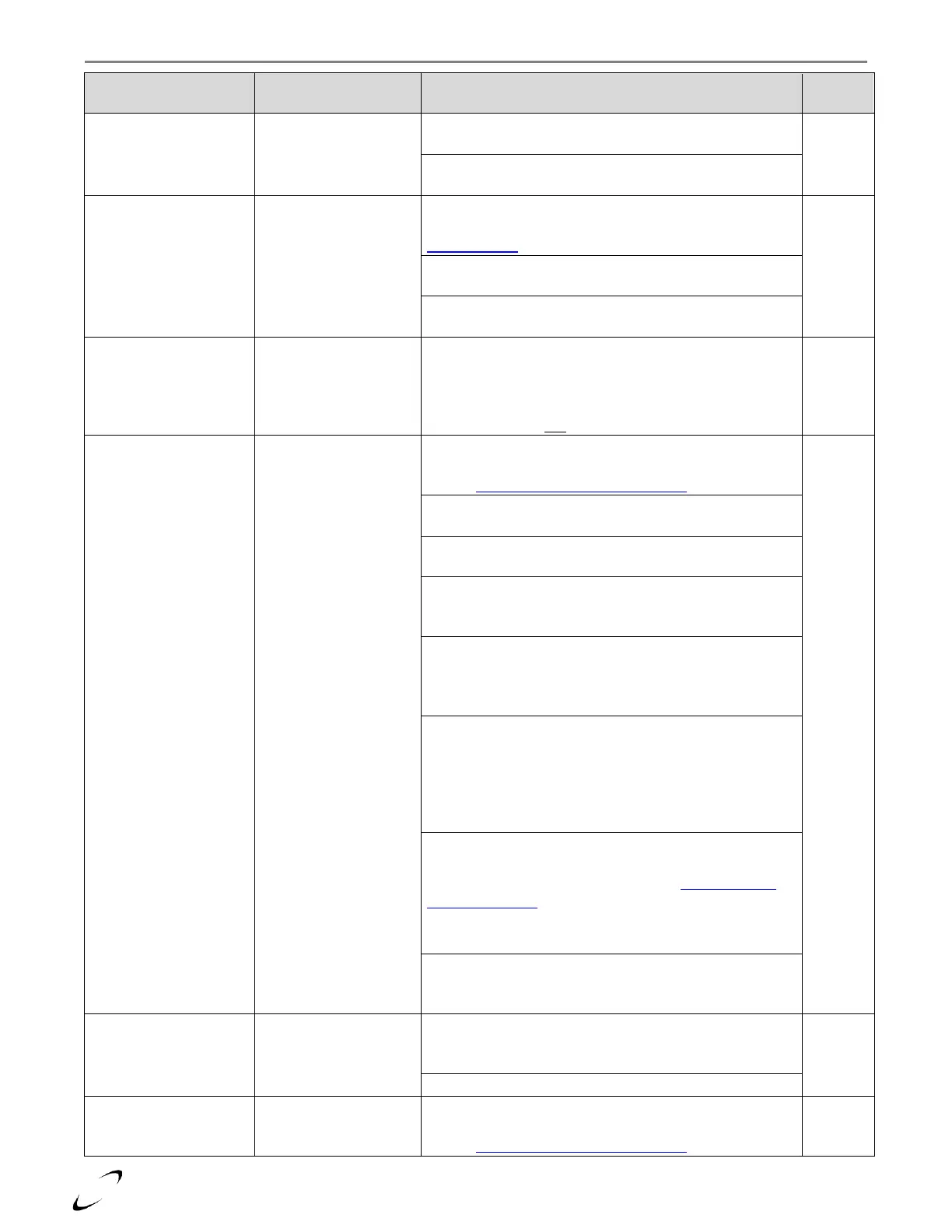

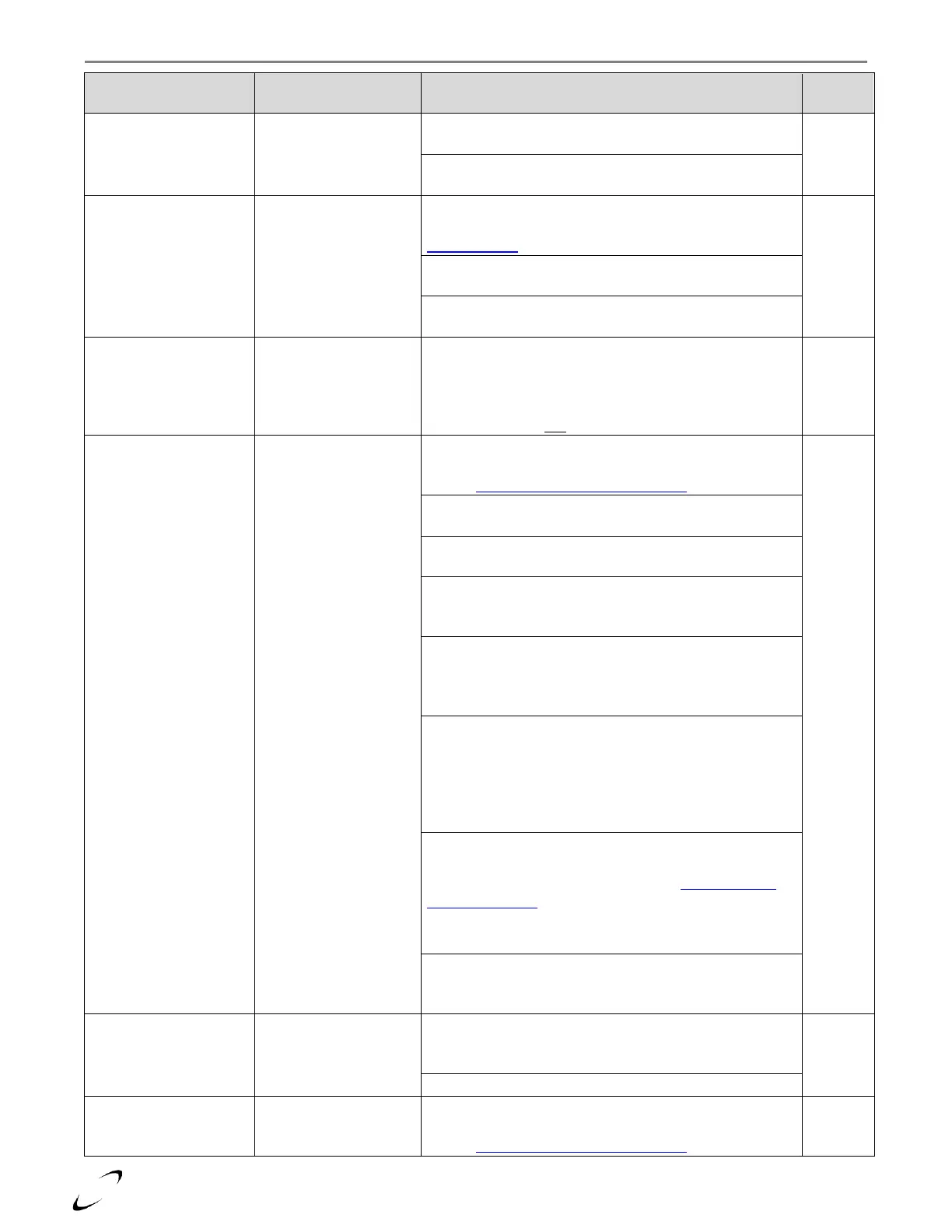

Installation and Operation Manual TFTN 085-199

412 – Room sensor

circuit open or short

circuit Zone 3

Room sensor circuit

open or short circuit

Zone 3

BUS wiring damaged – Inspect BUS wiring for bad

connections

Damaged PCB – If nothing is wired to the BUS

connections, replace the PCB.

441 – Follower Boiler

Missing from BUS

Follower Boiler Missing

from BUS

Single boiler configured as a Manager boiler – if this is a

stand-alone boiler, set Boiler Address = Single Boiler, see

Cascade Setup section

Follower BUS wires disconnected – Inspect BUS wiring for

damage or shorts, BUS wiring is polarity sensitive.

Follower boiler turned off – ensure power is on for all

boilers in cascade

460 – External safety

lock

Open circuit at AUX

LIMIT

External limit switch wired to AUX LIMIT input is open –

check device. If an external limit switch is not being used,

place a jumper across AUX LIMIT.

NOTE: error type is Manual Reset if parameter 24.6.5 is

set to “Safety lock not volatile”

501 1 – Ignition failed

(x3)

Boiler failed to sense

flame signal during

ignition (3x in a row)

Improper Gas pressure – verify that the gas pressure

during an ignition attempt is within the range specified in

section 9.0 – Gas Valve and Burner Setup.

Blocked air-intake – remove front cover and inspect the

venturi and boiler air inlet silencer for debris.

Blocked exhaust – inspect exhaust for proper slope to

boiler and possible restrictions or blockages

Blocked condensate drain – inspect condensate drain, if

the drain was clogged water may have entered the gas

valve. If the valve was wet, it must be replaced.

Improper LP conversion – check conversion instructions,

increase the gas flow by adjusting the input screw. **A

combustion test must be performed if the gas valve is

adjusted.

No spark – inspect the igniter for cracks or warping

(electrode gap should be 3/16"-1/4"). With the gas supply

valved off and the igniter removed, observe the spark

during the trial for ignition – it should spark for 3-5

seconds. If there is no spark check that the spark

transformer receives 120VAC during the ignition trial.

Improper combustion settings – adjust the gas valve

Throttle Screw to increase the gas flow. Once the boiler

remains lit set combustion. See section 9.0 – Gas Valve

and Burner Setup.

Warning: this process may only be performed by a

qualified technician with a combustion analyzer

Faulty flame sensor – if the boiler lights well and has a

strong flame, replace the flame sensor, and inspect the

flame sensor harness for shorts or damage.

502 – Flame detected

out of sequence

Flame detected before

the gas valve was

turned on

Faulty flame sensor – check the flame sensor and wiring

for damage, water or other possible shorts to ground

(replace flame sensor)

Faulty PCB – if problem persists, replace the PCB.

504 – Flame lost ten

times during run

Flame signal lost during

run (10x in a row)

Improper Gas pressure – verify that the gas pressure

during an ignition attempt is within the range specified in

section 9.0 – Gas Valve and Burner Setup.

Loading...

Loading...