3. ENGINE

3-

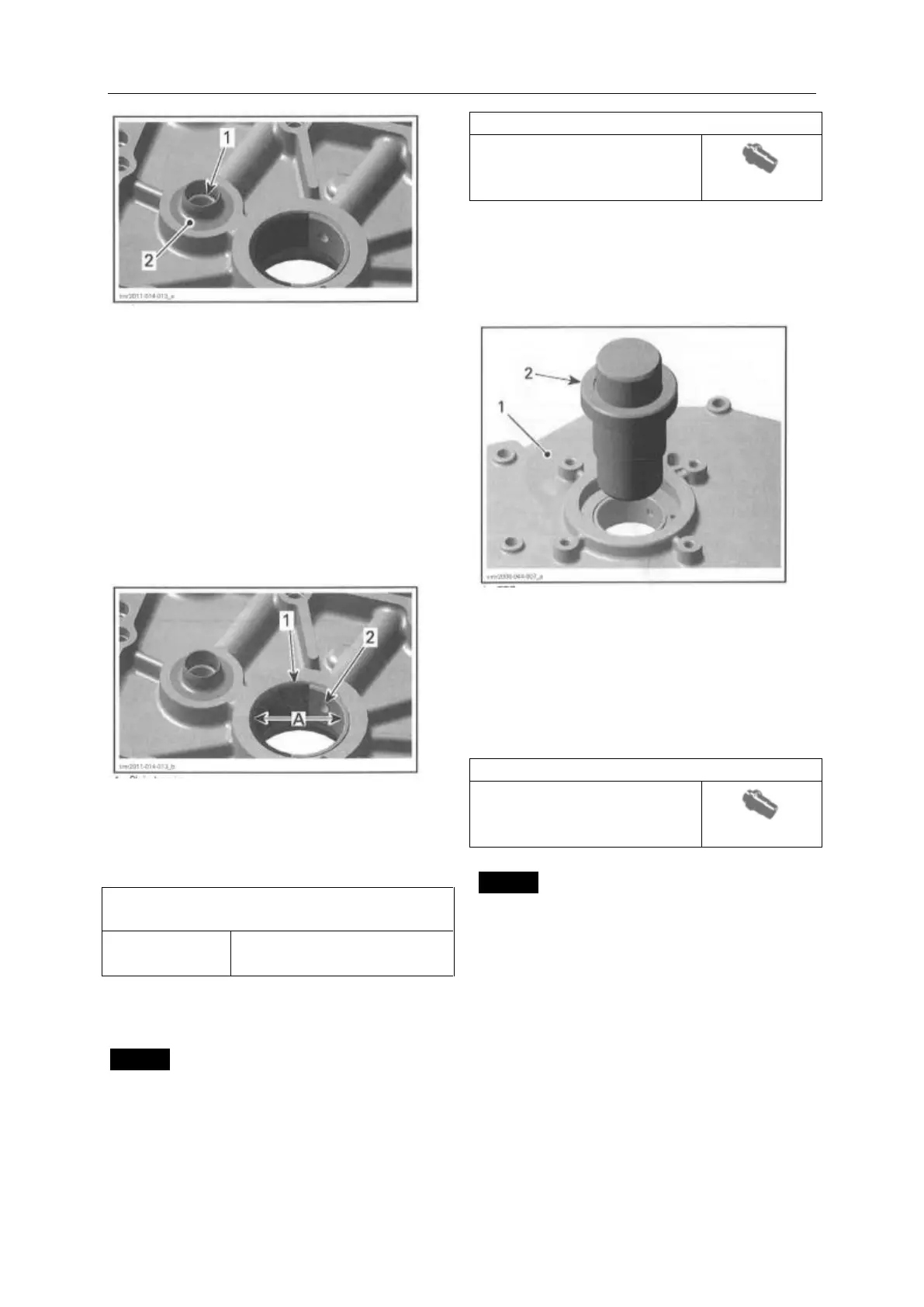

1. Oil breather bore

2. Surface of sealing sleeve

Check plain bearings for scorings or other

damages.

NOTE: Measure plain bearing inside diameter

(PTO cover) and compare to crankshaft journal

Diameter (PTO cover bearing). Refer to CRANK

SHAFT in this section. Replace if the

measurement is out of specification.

1. Plain bearing

2. Oil bore

A. Measure plain bearing inside diameter

PLAIN BEARING INSIDE DIAMETER

(PTO COVER)

Plain Bearing Replacement (PTO Cover)

Plain Bearing Removal

NOTICE Unless otherwise instructed, never use a

hammer to install plain bearings. Use a press only.

Carefu1ly remove the PT0 oil seal with a

screwdriver, without damaging the PT0 cover.

Press out the plain bearings from the outside

towards the inside.

PLAIN BEARING

REMOVER /

UNSTALLER

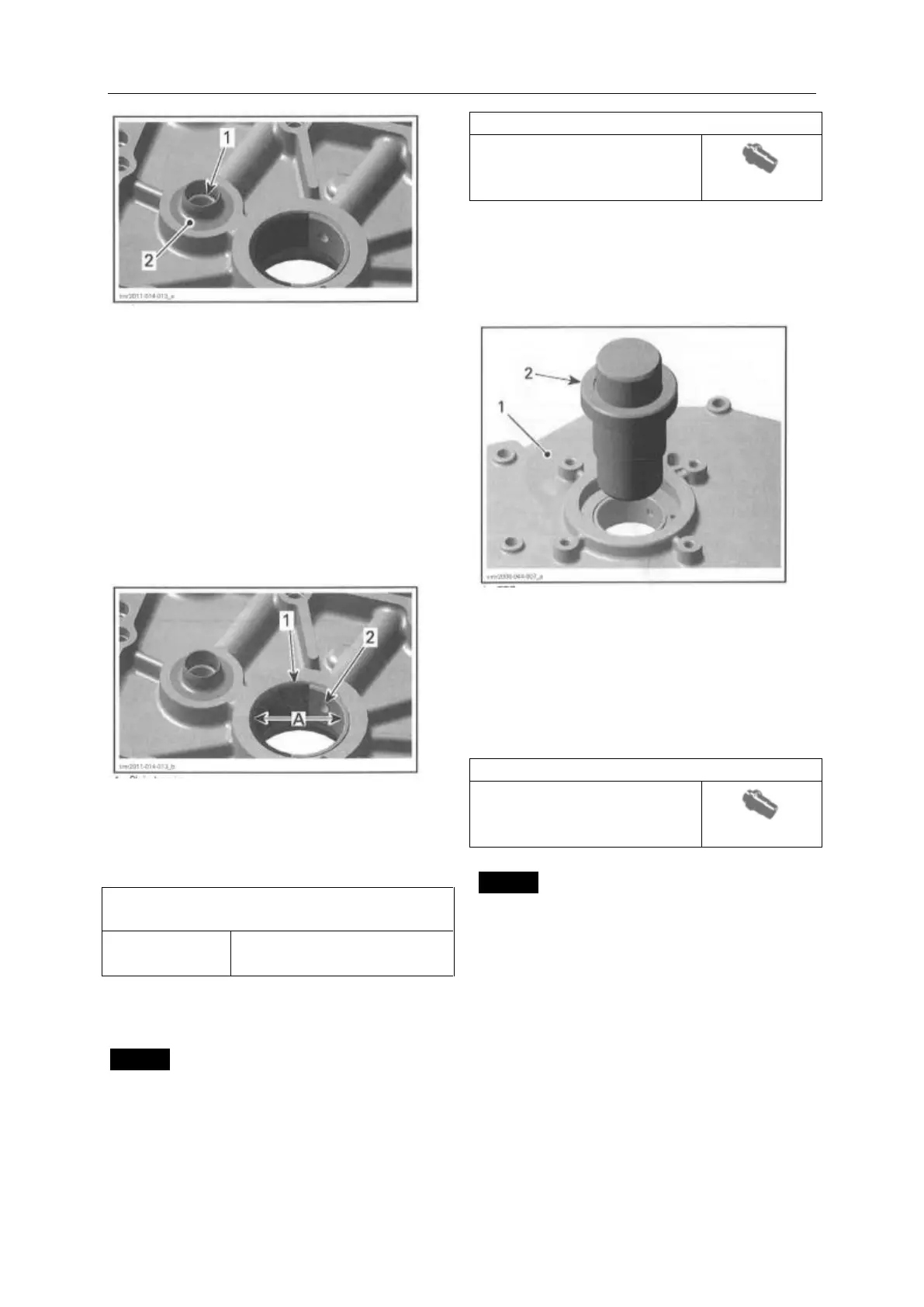

The PT0 cover has to be supported from below

with suitable support with straight surface, in order

to prevent damage of the sea11ng surface.

1. PTO cover

2. Plain bearing remover /installer

Plain Bearing Installation

NOTE: Do not lubricate plain bearings and/or PT0

cover for installation.

Install plain bearings in a cool PTO cover.

PLAIN BEARING

REMOVER /

UNSTALLER

NOTICE Mark position of oil bore on PTO cover

and on plain bearing remover/installer. Align mark

on plain bearing remover/installer with mark on

PTO cover.

Loading...

Loading...