3. ENGINE

3-

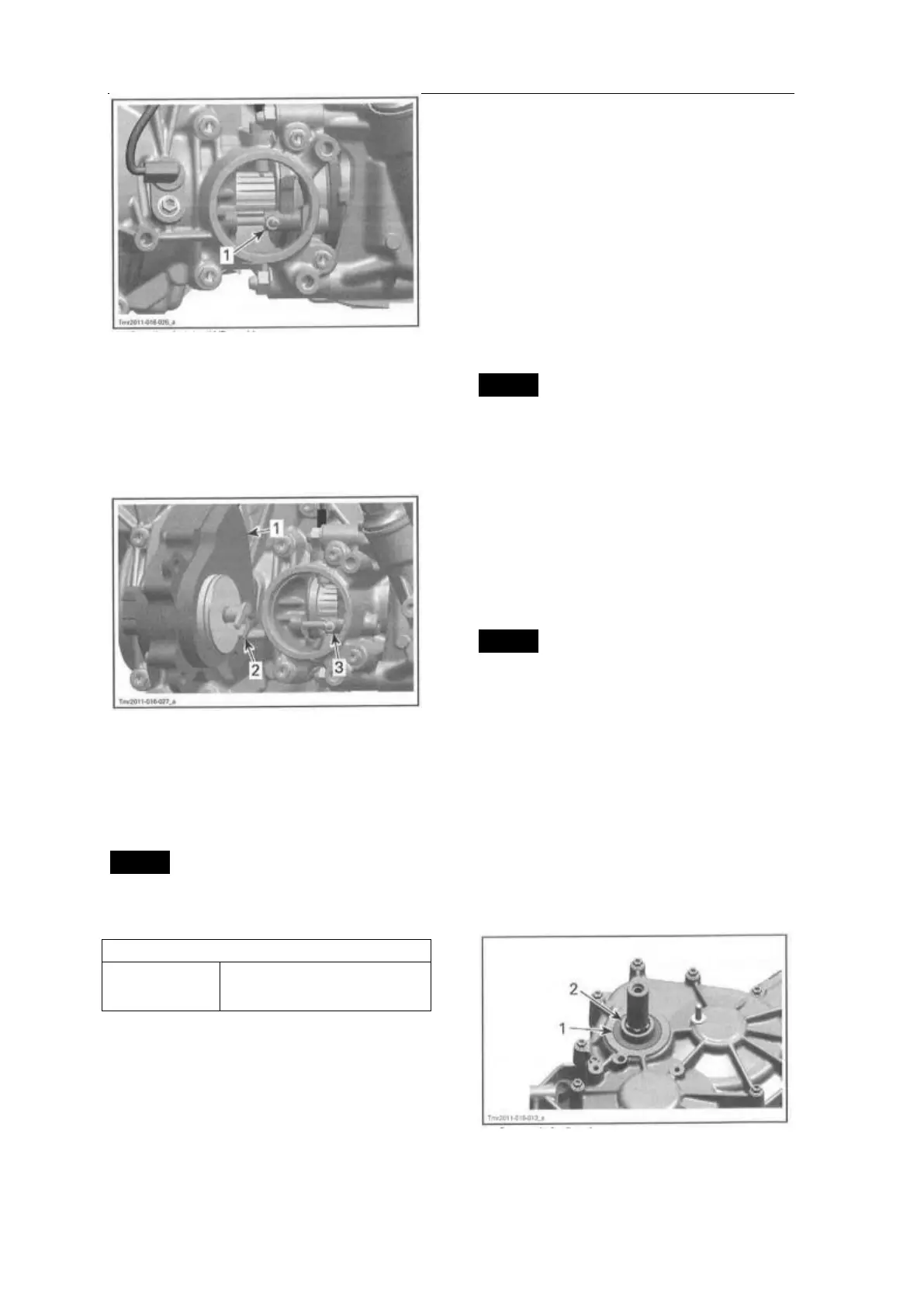

1. Coupling fork in 4WD position

Align the actuator fork with the pin on couplin9

fork then push the actuator in the housing. See

the following illustration to position the

actuator correctly.

1. Actuator

2. Aotuatorfor1l1

3. Coupling fork

Rotate the actuator counterclockwise until it

orients itself to mounting position.

NOTICE Do not cut or break the actuator

O-ring.

Install all actuator screws and tighten them.

25N.m±3N.m

(18 lbf.ft±2 lbf.ft

Connect actuator.

Lift the front of vehicle.

Turn front wheels. The front propeller shaft

should not turn(the PARK position must be

selected).

If the front propeller shaft turns, the actuator is

not installed correctly. Remove actuator and

reinstall it.

Place ignition switch to 0N position and select

the 2WD position.

Turn front wheel again. The front propeller

shaft should turn easily.

If the front propeller shaft does not turn, the

actuator is not installed correctly. Remove

actuator and reinstall it.

NOTICE Refill missing gearbox oil, refer to

GEARBOX OIL REPLACEMENT in

PERIODIC MAINTENANCE PROCEDURES

subsection.

Install all other removed parts. GEARBOX

OIL SEALS

Gearbox Oil Seal Replacement

Replace oil seals if they are brittle, hard or

dam- aged.

A small flat screwdriver can be used to remove

most of these oil seals.

NOTICE Avoid scoring parts during oil seal

removal.

When replacing an oil seal, take this

opportunity to inspect the following:

-Check bearings behind each oil seal for

contamination and/or metal shavings.

-Check oil seal running surfaces for scratches.

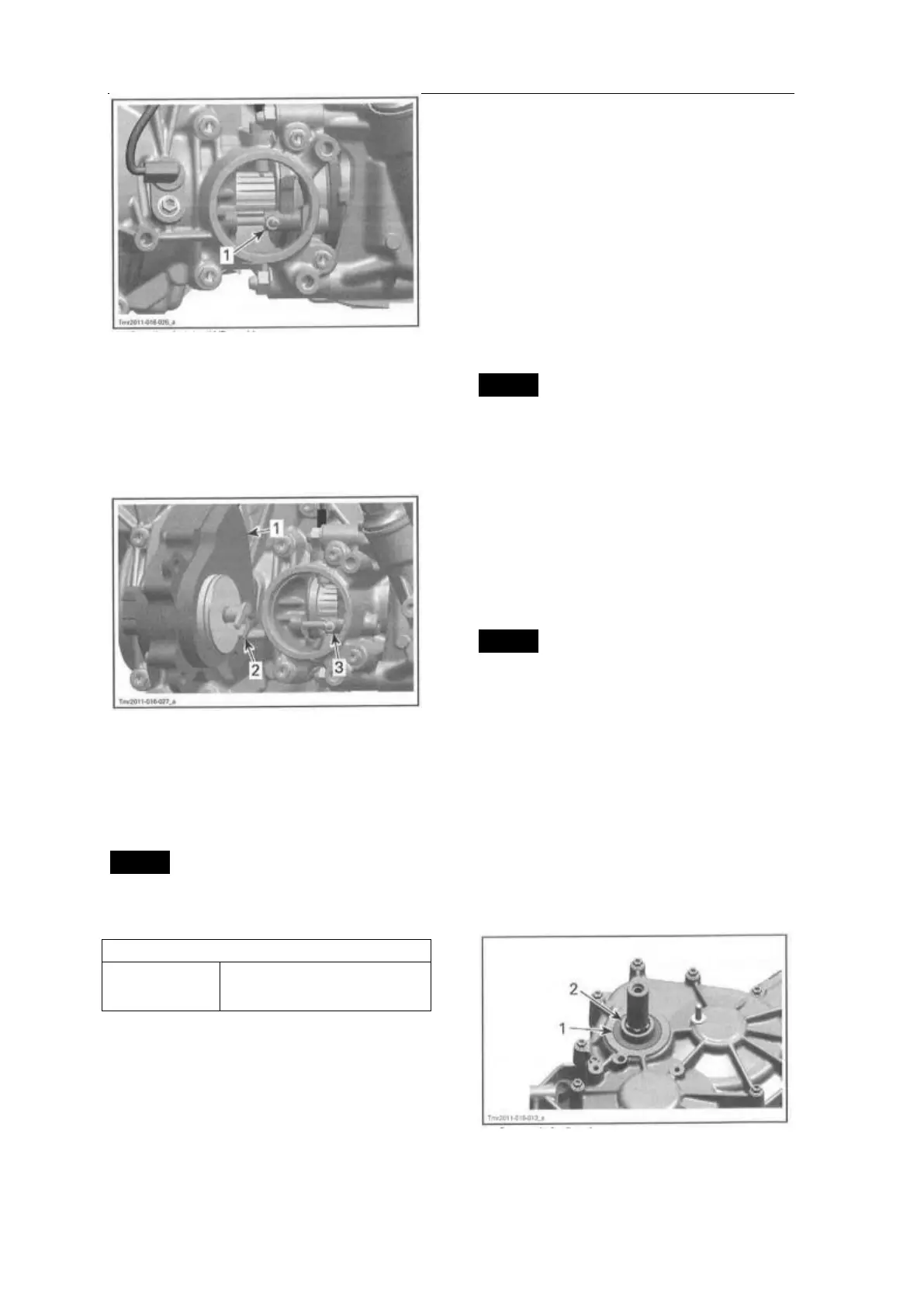

Countershaft Oil Seal

To replace the countershaft oil seal, remove:

-Drive and driven pulleys

-CVT air guide.

NOTE: When oil seal is removed also inspect

O-ring behind distance sleeve.

1. Countershaft oil seal

2. Distance sleeve

Loading...

Loading...