3. ENGINE

3-

Gearbox Inspection

Always verify for the fol1owing when

inspecting gearbox components:

- Gear teeth damage

- Worn or scoured bearing surfaces

- Rounded engagement dogs and slots

- Worn shift fork engagement groove

- Worn splines on shafts and shifting sleeves.

Bearings

Check if ball bearings turn freely and smoothly.

Check all bearings, bearing points, tooth flanks

and taper grooves.

Free Pinions

NOTE: Always replace snap rings and use

special pliers to install them.

Check free pinions for wear.

TYPICAL

1. Micrometer

2. Free pinion

29.000 mm

to29.013mm

(1.1417in

to1.1422in)

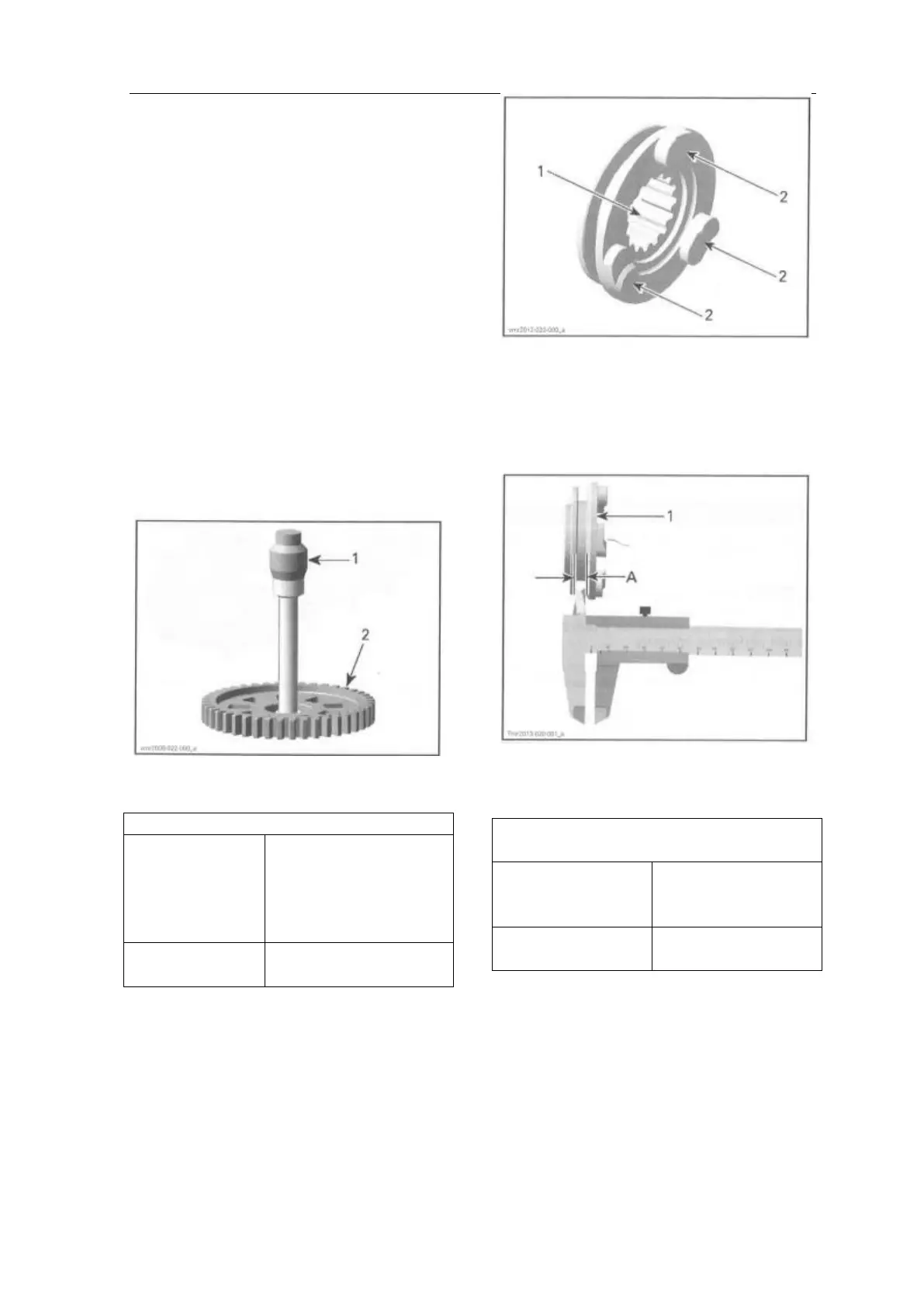

Shifting Sleeves

Check shifting sleeves for worn inner splines

and rounded or damaged engagement dogs.

TYPICAL

1. Inner splines

2. Engagement dogs

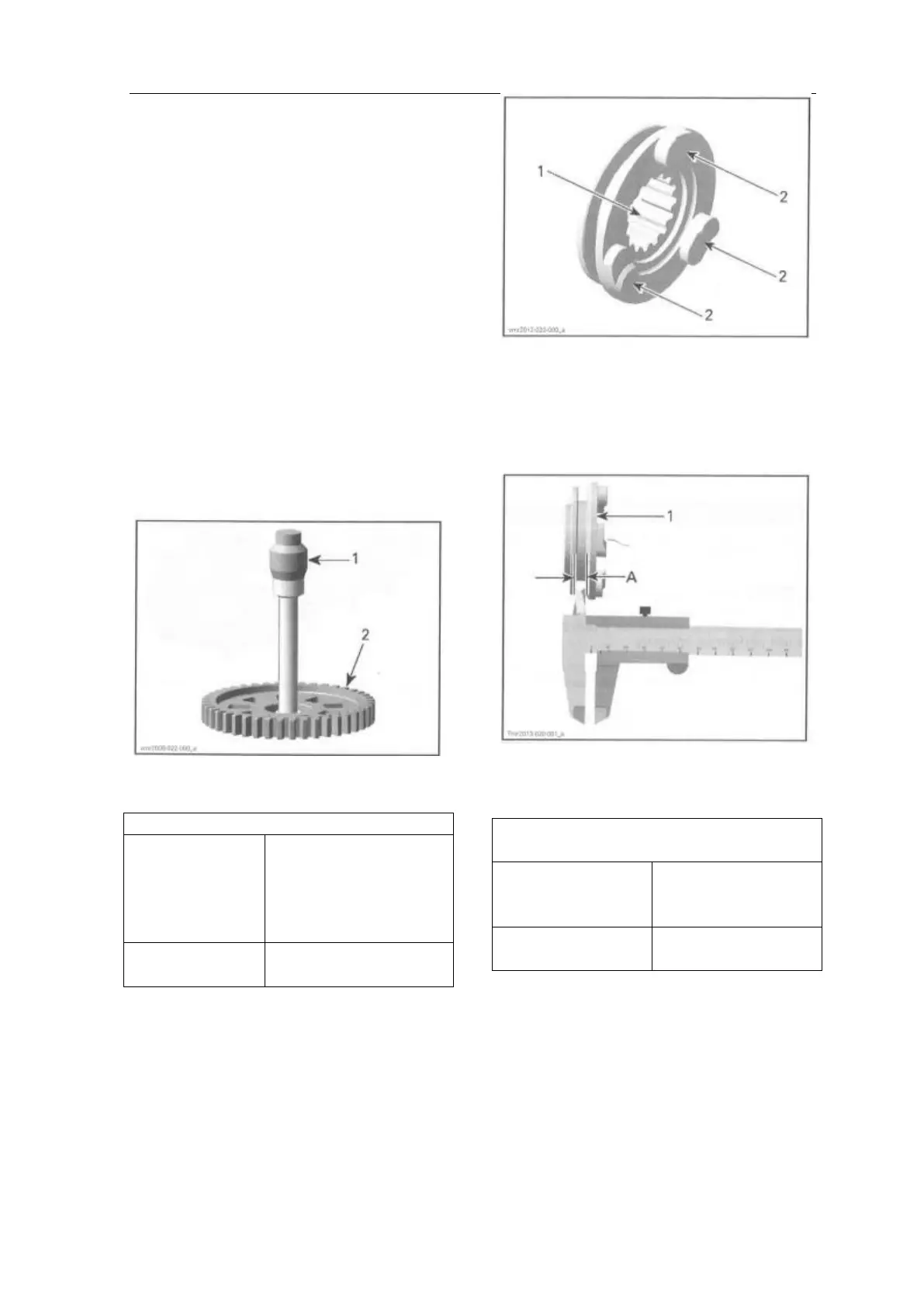

Measure the width of shift fork engagement

groove.

TYPICAL

1. Shifting sleeve

A. Width of shift fork engagement groove

WIDTH 0F SHIFT FORK

ENGAGEMENT GROOVE

5.30 mm to5.40

mm

(.209in to.213in)

Shafts

Check bearing pin of reverse intermediate gear

for wear.

Loading...

Loading...