3. ENGINE

3-

Rotor Installation

For installation, reverse the removal procedure.

However, pay attention to the following.

Use PULLEY FLANGE CLEANER (P/N413 711

809) to clean following:

- Crank shaft taper

- Oil passage in crank shaft taper

- Thread in crankshaft

- Rotor taper

- Oil bore in rotor.

NOTICE Taper on crankshaft and rotor must be

free of grease.

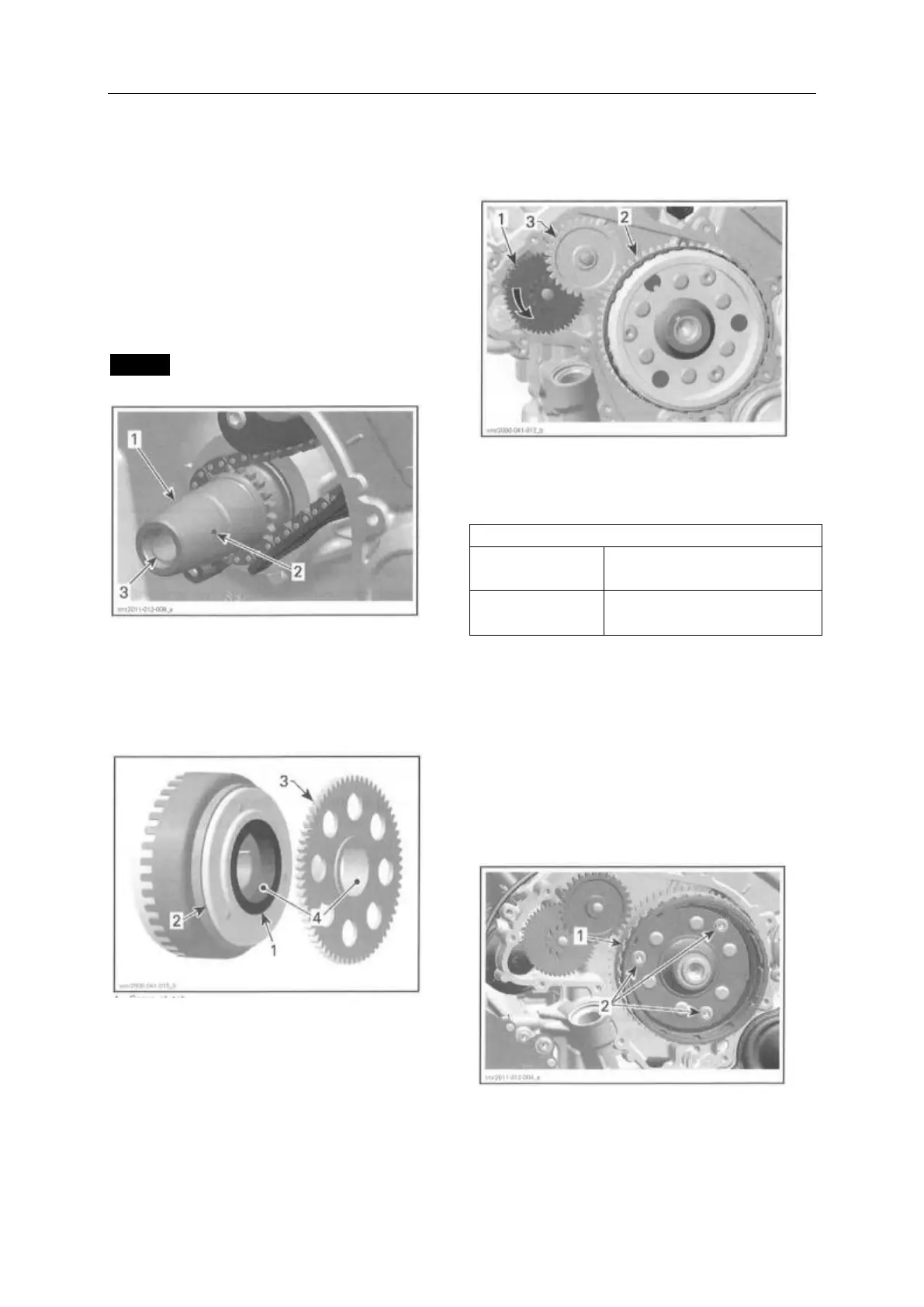

1. Crankshaft (MAG side)

2. Oil passage

3. Threads

Oil sprag clutch and instal1 sprag clutch gear.

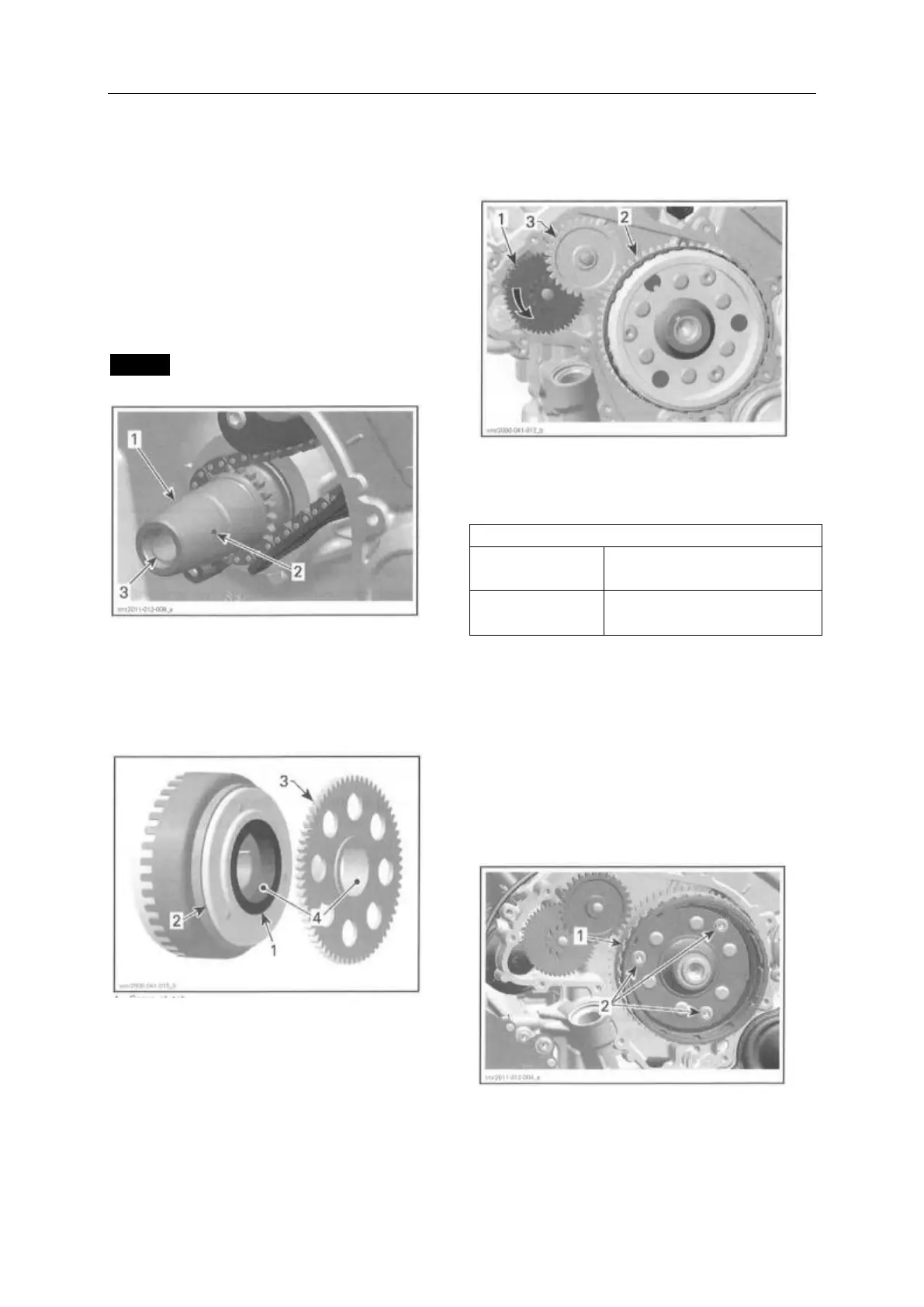

1. Sprag clutch

2. Sprag clutch housing

3. Sprag clutch gear

4. Apply engine oil here

Slide rotor onto crankshaft. The woodruff key and

the keyway must be aligned.

Rotate starter double gear counterclockwise to

align intermediate gear teeth with sprag clutch

gear.

1. Starter double gear

2. Sprag clutch gear

3. Intermediate gear

LOCTITE648 (GREEN)

(P/N413 711 400)

150N·m±10N·m

(111 lbf·ft±7lbf·ft)

SPRAG CLUTCH

Sprag Clutch Removal

Remove MAGENTO CIVER. See procedure in

this subsection.

Heat screws in order to break the Loctite.

Loosen sprag clutch housing screws located inside

rotor.

1. Rotor

2. Sprag clutch housing screws

Remove rotor(refer to/11'07-0/li'in this subsection).

Remove sprag clutch gear.

Loading...

Loading...