3. ENGINE

3-

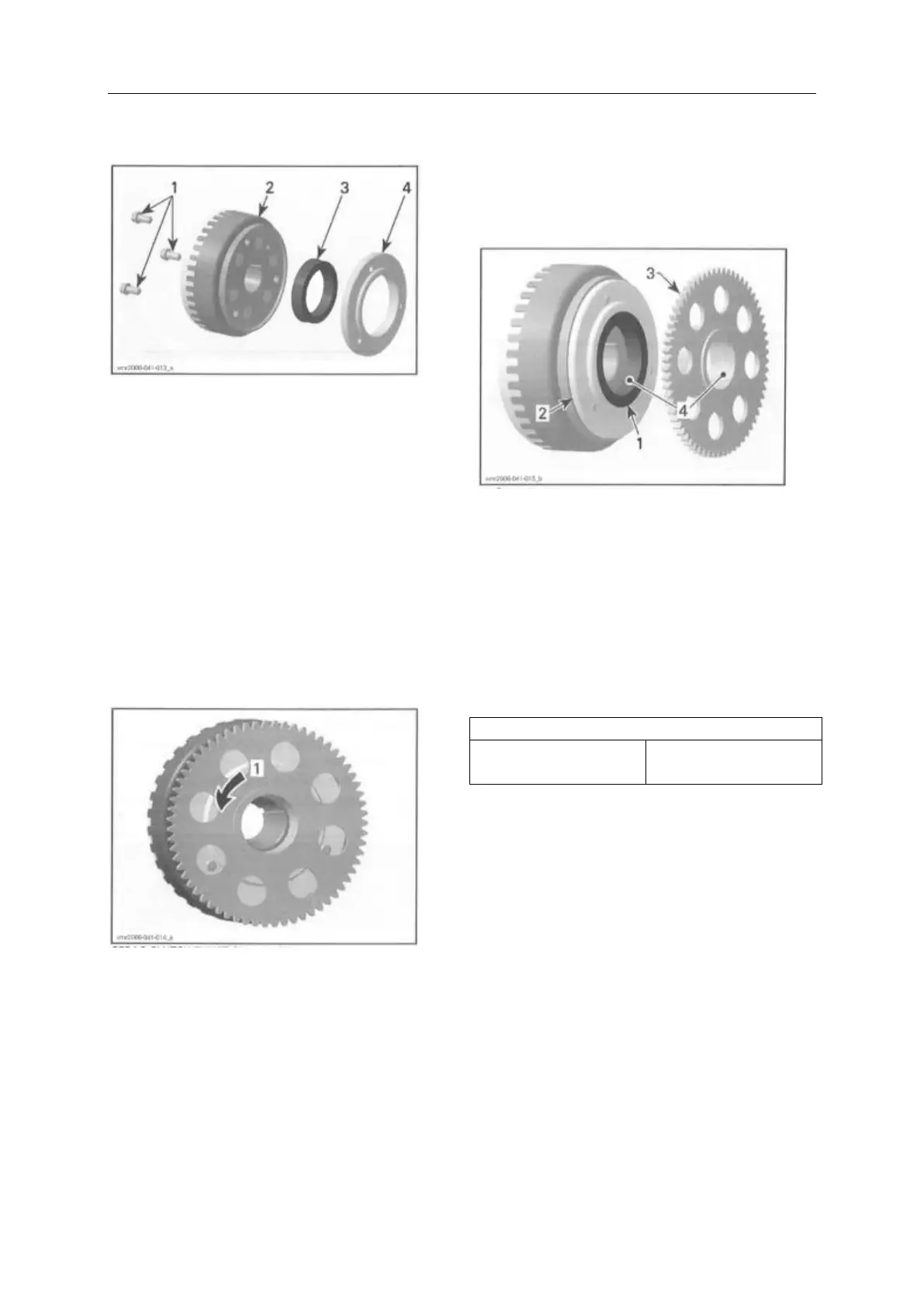

Remove sprag clutch housing screws and sprag

clutch housing.

1. Sprag clutch housing screws

2. Rotor

3. Sprag cluth

4. Sprag clutch housing

Sprag Clutch Inspection

Inspect sprag clutch and sprag clutch housing for

wear and damage.

Also check the collar of the sprag clutch gear.

Rotate sprag clutch gear in sprag clutch.

NOTE: Sprag clutch must lock in

counterclockwise direction.

SPRAG CLUTCH FUNCTION TEST

1. Lock

NOTE: Sprag clutch, housing and gear must be

replaced at the same time, if damaged.

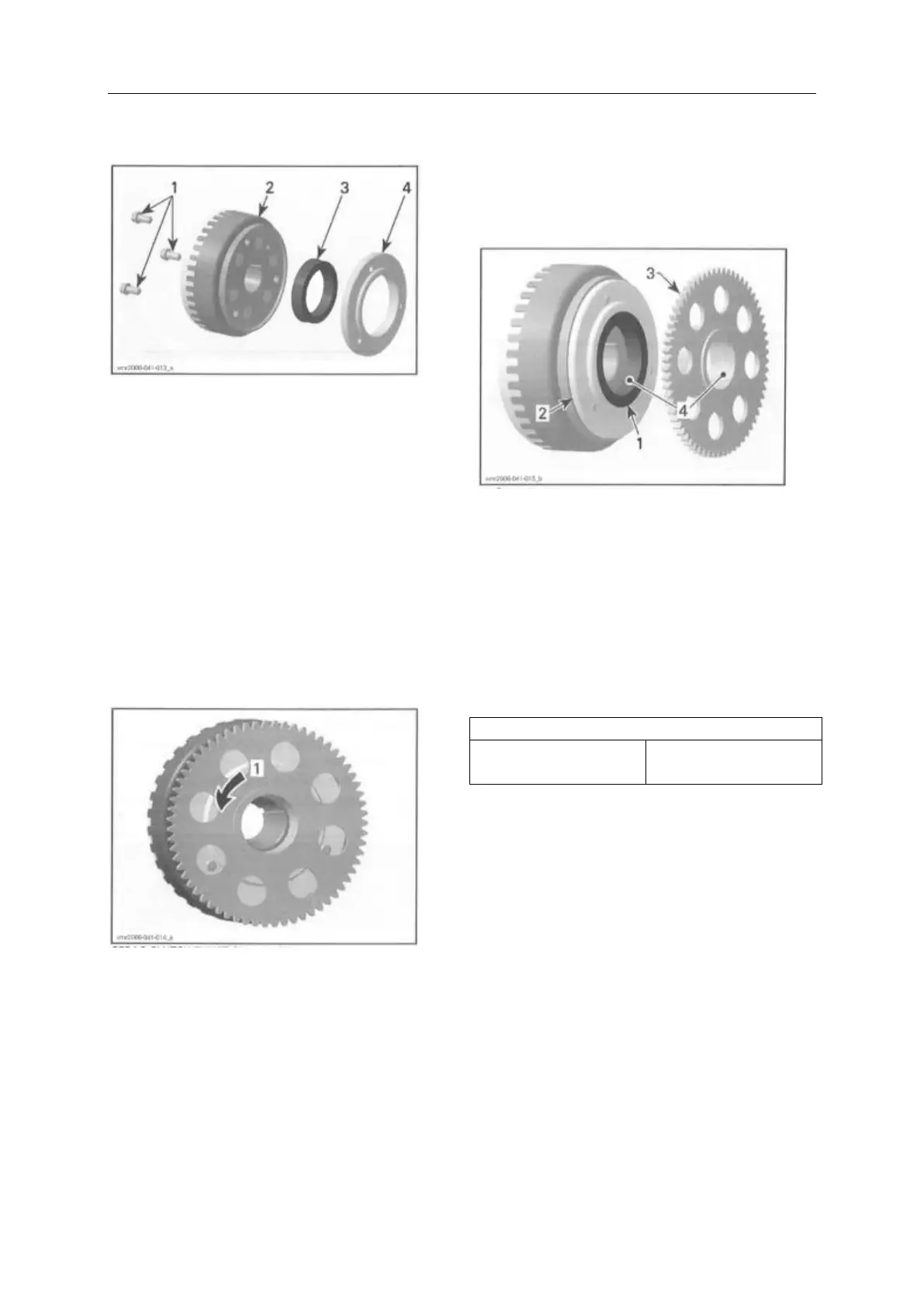

Sprag Clutch Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

Apply LOCTITE648 (GREEN) (P/N413 711 400)

on threads of sprag clutch housing screws.

Install screws but do not torque yet.

Apply engine oil on sprag clutch and sprag clutch

gear needle bearing.

1. Sprag clutch

2. Sprag clutch housing

3. Sprag clutch gear

4. Apply engine oil here

Insta11 rotor, refer to ROTOR in this subsection.

Tighten sprag clutch housing screws to

specification.

SPRAG CLITCH HOUSING SCREW

30N·m±2N·m

(22 lbf·ft±1lbf·ft)

SPRAG CLUTCH GEAR

Sprag Clutch Gear Removal

Remove ROTOR. See procedure in this

subsection.

Pul1 sprag clutch gear out of the rotor.

Loading...

Loading...