10044 Planer OLIVERMACHINERY.NET 39 | Page

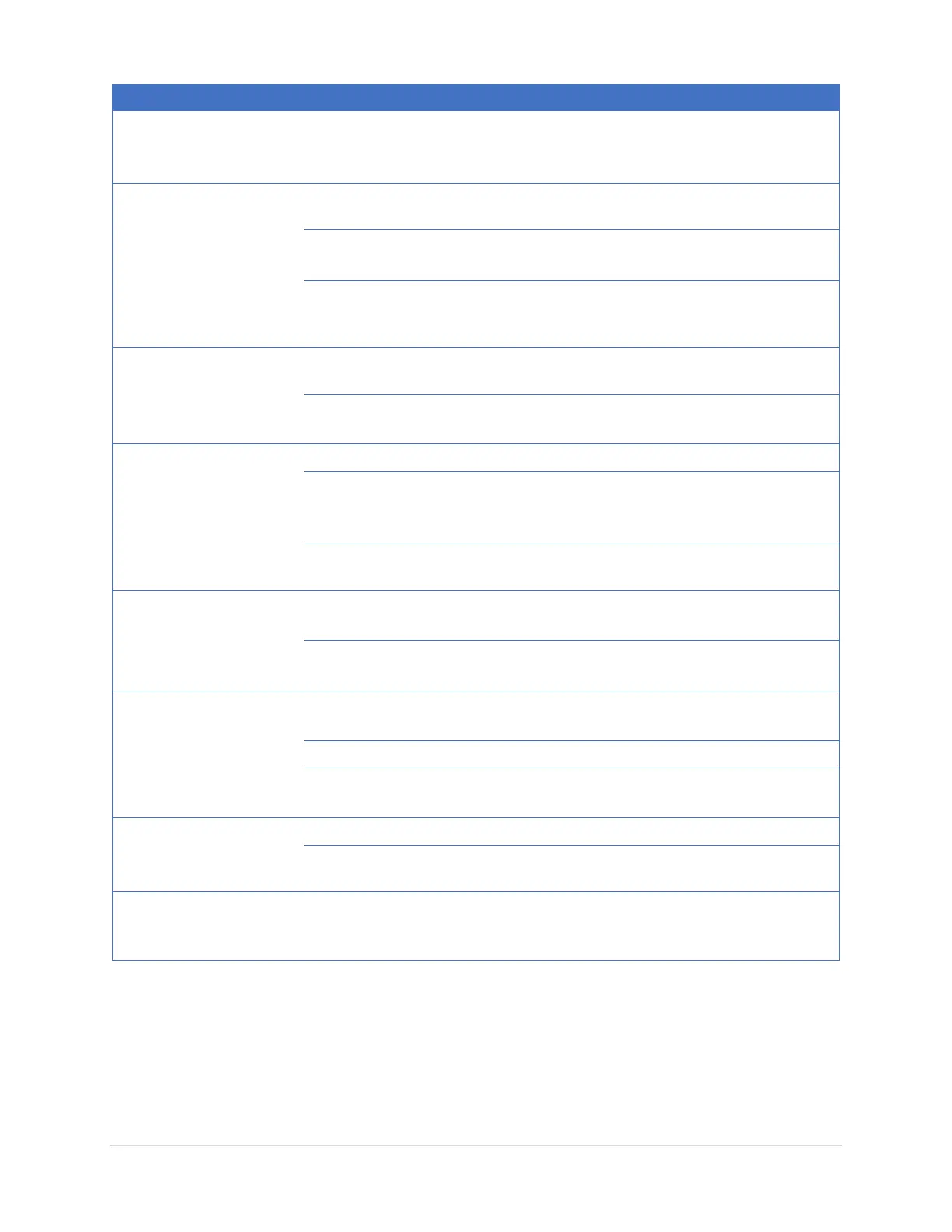

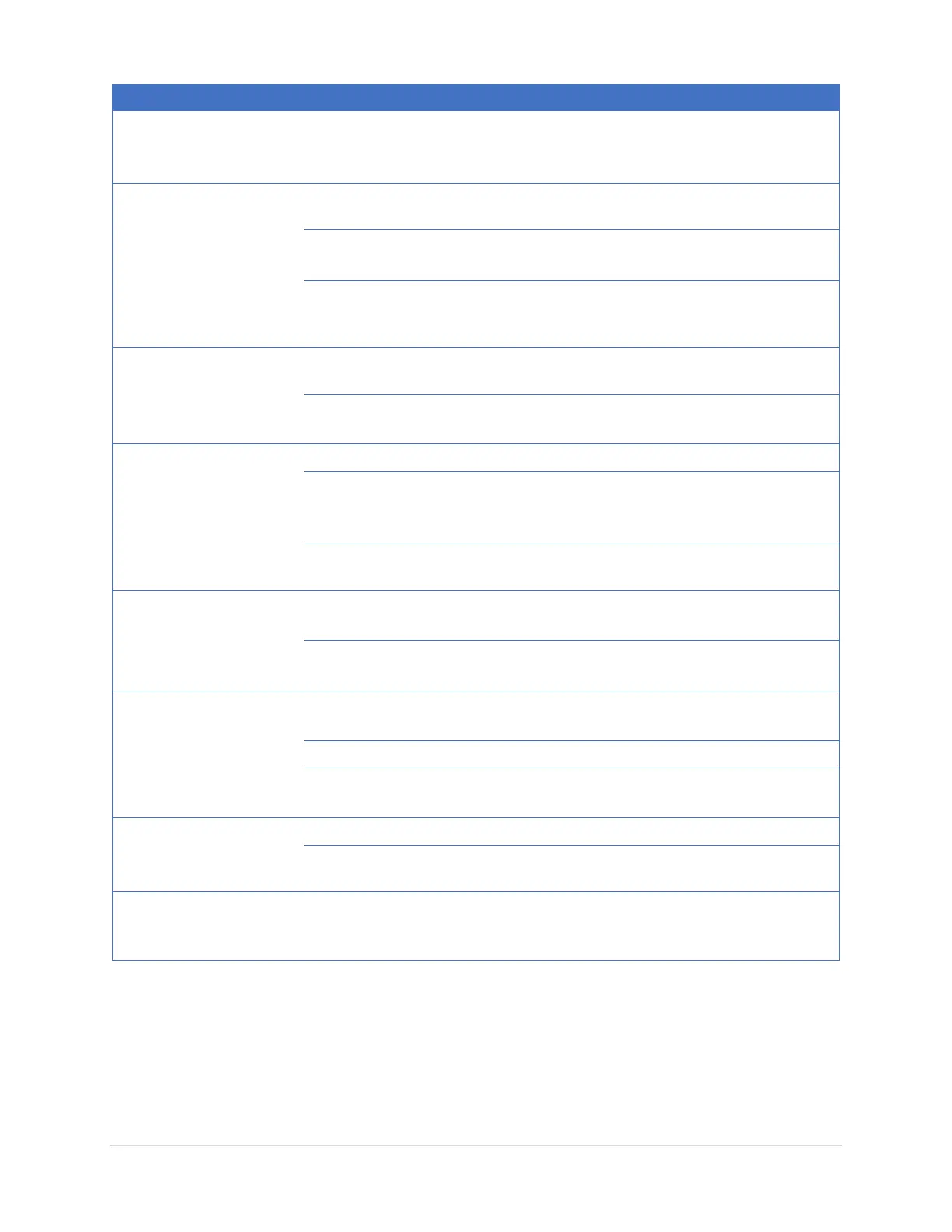

twisted.

before the cut.

Planer is not the tool to flatten a twisted

workpiece. Flatten one side with a jointer

before proceeding with a planer.

Extension wing slope

down.

Adjust extension wing elevation.

supported properly.

Use auxiliary rollers to support the long

workpiece.

sniping can happen

Add an extra 6” length on a workpiece for

planing, and then trim off the ends.

chipping

Aggressive depth of cut

for the wood type.

Do not plane end grain. Use a drum sander

instead.

surface.

Rotate/replace cutter insert.

grain; or knots.

Avoid planing workpieces with knots. Plane

with grain whenever possible. Moisten

problematic areas before planing.

Too much material

removed in one pass.

workpiece surface.

Remove all buildups on infeed, outfeed, and

table rollers.

Inefficient chip removal.

Check the dust collection system for suction.

too high.

Only process wood with less than 20%

moisture content.

Rotate/replace cutter insert.

to have fuzzy grain.

Use sharp cutters.

Rotate/replace cutter insert.

Cutting depth too

shallow.

running along the

Rotate/replace cutter insert.

Loading...

Loading...