7

O.M.A.C. s.r.l.

Via Giovanni Falcone, 8 42048 Rubiera (RE) - Italy Tel.0522/629371 - 629923 Fax 0522/628980

E-mail:info@omacpompe.com SitoWeb:www.omacpompe.com

Rev.4 del 01/2011 O.M.A.C. s.r.l.

Chap.3 - pag.

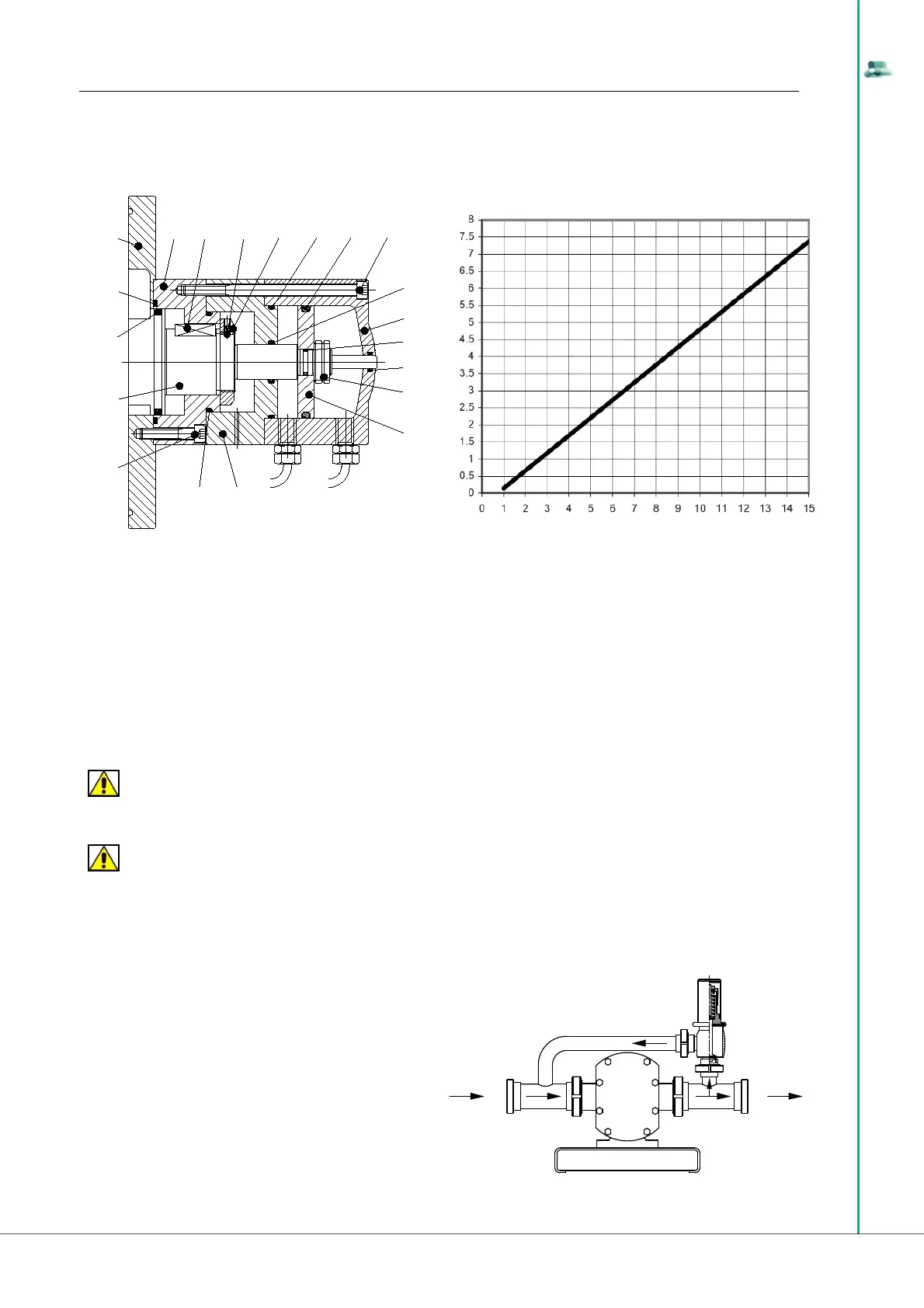

The adjustment of the pneumatic safety valve is carried out on site because it must be connected directly to the compressed air circuit on site. To adjust

it is recommended to use, as reference for the pressure and sizing of the compressed air unit, the graph below showing the correspondence between the

pressure inside the pump and the pressure in the valve. To prevent continuous vibrations, the safety valve must be adjusted in such a way that it starts

working at a pressure 10% higher than the working pressure.

When the force the pneumatic circuit exercises on the valve is higher than that exercised by the fl uid, the valve stays closed; on the contrary the valve is

activated generating discharge volumes that enable balancing of forces, inside the pumping chamber.

Before calibrating the pneumatic safety valve, one must calibrate the pneumatic circuit of the Customer, with a pressure value as follows:

• on the basis of the data carried in the LDPU technical sheet, detect the unit working pressure;

• with this data consult the graph shown on the next page to obtain the pressure value with which the safety valve must be calibrated.

Once one has obtained these values, proceed as indicated below:

• start the “B series lobe displacement Pump Unit” with the safety valve connected to the compressed air circuit;

• with reference to the indications on the manometer on the suction duct in proximity to the LDPU suction inlet, acting on the pneumatic pressure

regulator, manually increase or decrease the pressure value of the pneumatic circuit until reaching the critical balance value, i.e. the value obtained from

the graph.

To prevent continuous vibrations, the safety valve must be adjusted in such a way that it starts working at a pressure 10% higher than the working

pressure.

ATTENTION

The adjustment of the mechanical safety valve must be carried out on site by the Customer, since the recycle entity depends on the LDPU speed, on the

specifi c weight of the fl uid, as well as its viscosity.

ATTENTION

The operations described herein require at least two manometers, for pressure values, installed on the suction and delivery pipes, near the LDPU ope-

nings that connect it to the plant of the Customer.

C) EXTERNAL BRIDGE MECHANICAL SAFETY VALVE AND ADJUSTMENT

by-pass pressure / B Series pump correspondence

B Series pump pressure [bar]

by-pass pressure [bar]

91

72

95 98

97

104

93

96

94

92

99

107101

102

103

106

109

108

105

100

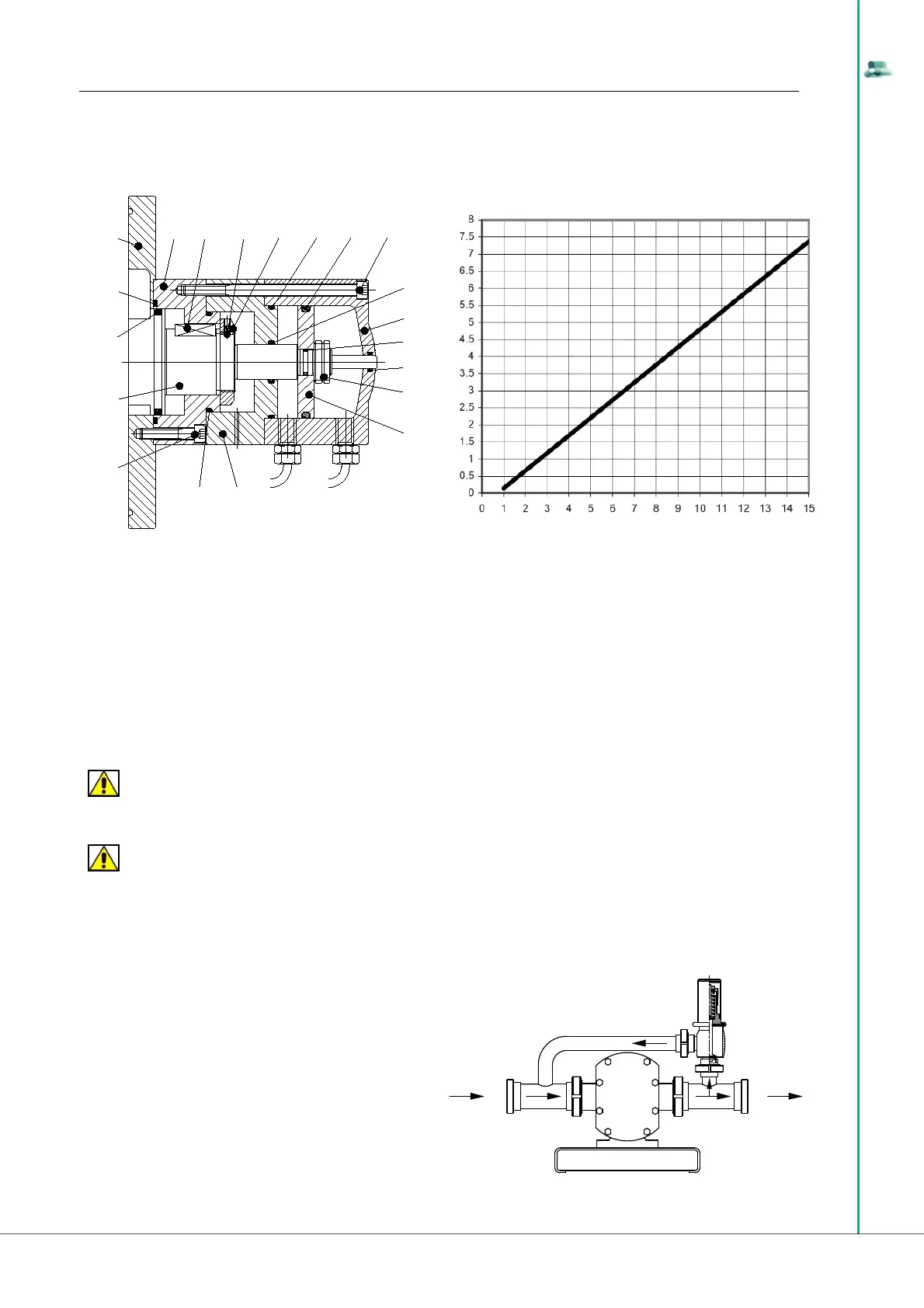

The external mechanical safety valve is made up of a spring

valve positioned on a pipe bridge that connects delivery and

suction and can also be used as a by-pass to let all or part of the

processed fl uid fl ow back.

To adjust the external bridge safety valve act on the spring

compression regulation, located on the upper part of the valve

body. The system composed in this manner is one-way so if one

inverts the direction of the LDPU, it is essential to invert the po-

sitioning of the valve as well that, in any case, must always be

on the delivery side.

One can choose various kinds of springs according to the

working pressure. The adjustment must be carried out on site,

acting manually on the special adjustment ring.

SUCTION

DISCHARGE

EXTERNAL BRIDGE

MECHANICAL SAFETY VALVE

Loading...

Loading...