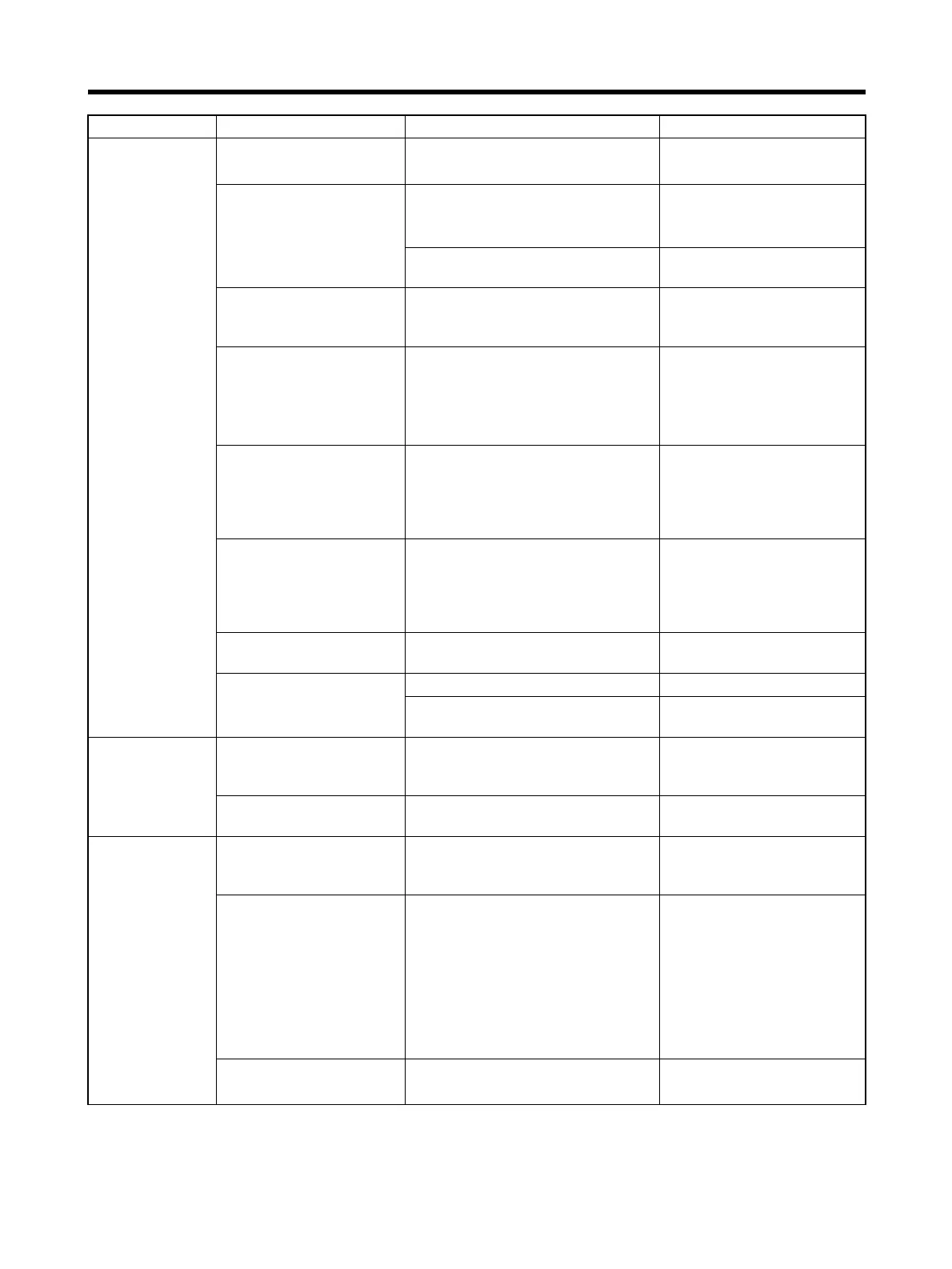

Chapter 5

5-13

Troubleshooting

The Servomotor

does not oper-

ate even when a

command is

given.

The RUN signal is OFF. Check the RUN signal’s ON and

OFF operation.

Input the RUN signal.

Correct the wiring.

The deviation counter

reset input (ECRST) is

ON.

Check the ON/OFF status of the

ECRST signal.

Turn OFF the ECRST sig-

nal.

Correct the wiring.

Pn200.1 (deviation counter reset)

setting is incorrect.

Reset Pn200.1 to match the

Controller.

An error occurred with

the RESET (alarm reset)

signal ON.

Check the ON/OFF status of the

RESET signal.

Turn the RESET signal OFF

and take measures accord-

ing to the alarm display.

Function switch settings

are incorrect.

Check function switch 6 (switch/

parameter setting).

If using function switch 3

(command pulse input set-

ting), turn OFF switch 6.

If using parameter Pn200.0,

turn ON switch 6.

Function switch 3 (com-

mand pulse input) setting

is incorrect. (When func-

tion switches are being

used.)

Check the Controller’s command

pulse type and the Servo Driver’s

command pulse mode.

Set the mode to match the

Controller’s command pulse

type.

Pn200.0 (command

pulse mode) setting is

incorrect. (When param-

eter setting is being

used.)

Check the Controller’s command

pulse type and the Servo Driver’s

command pulse mode.

Set the mode to match the

Controller’s command pulse

type.

Servomotor power lines

are incorrectly wired.

Check Servomotor power lines. Rewire correctly.

Command pulse is incor-

rectly wired.

Check the command pulse wiring. Rewire correctly.

Check the command pulse volt-

age.

Connect a resistor match-

ing the voltage.

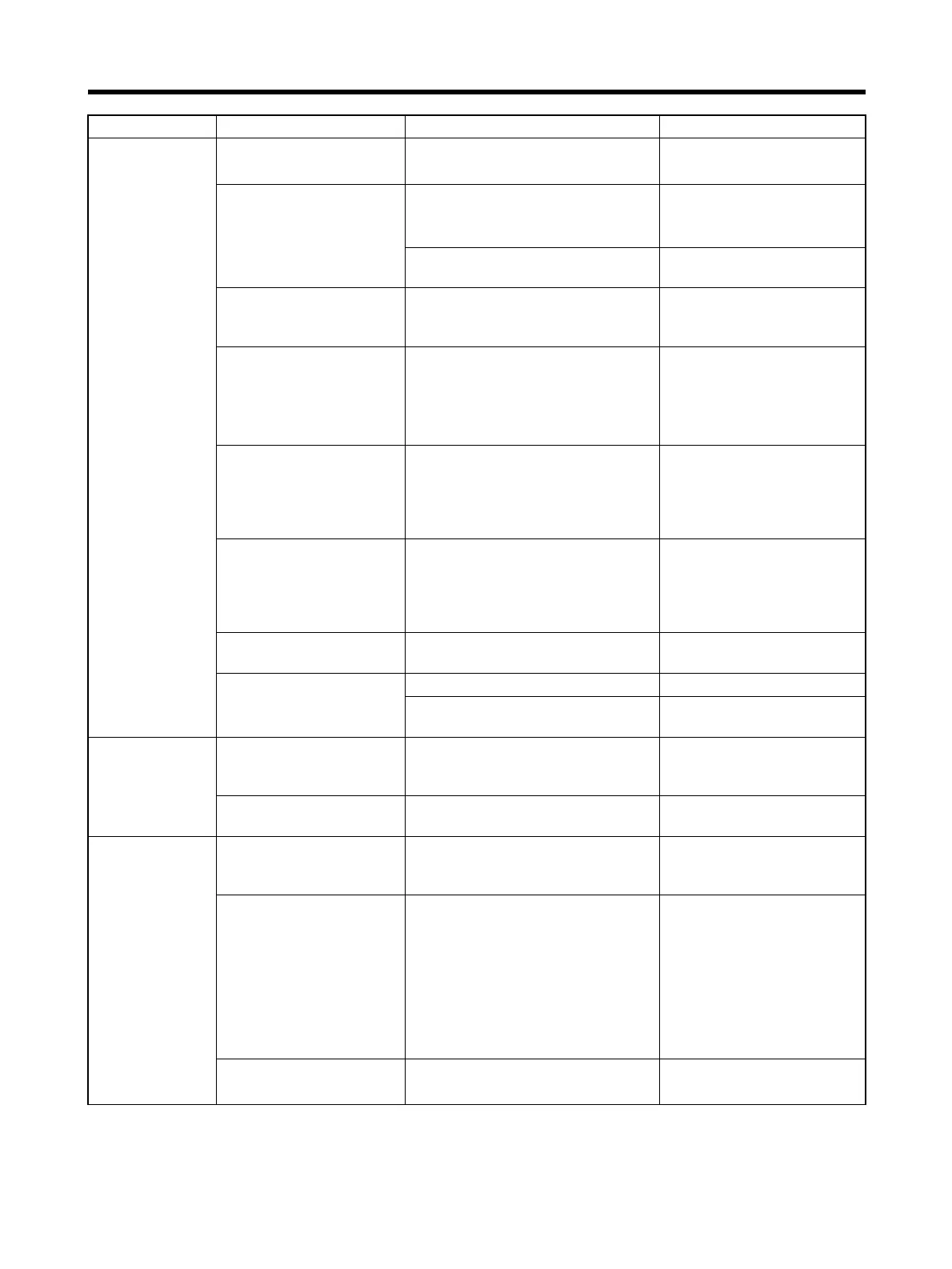

The Servomotor

operates

momentarily, but

then it does not

operate.

The Servomotor power

lines or encoder lines are

wired incorrectly.

Check the Servomotor power line

U, V, and W phases, and the

encoder line wiring.

Correct the wiring.

The command pulse is

more than 250 kpps.

Check the Controller’s command

pulse frequency.

Reset the command pulse

to 250 kpps max.

Servomotor

operation is

unstable.

The Servomotor power

lines or encoder lines are

wired incorrectly.

Check the Servomotor power line

U, V, and W phases, and the

encoder line wiring.

Correct the wiring.

There are eccentricities

or looseness in the cou-

pling connecting the Ser-

vomotor shaft and the

mechanical system, or

there are load torque

fluctuations according to

how the pulley gears are

engaging.

Check the machinery.

Try operating the Servomotor with-

out a load.

Adjust the machinery.

Gain is wrong. --- Use autotuning.

Adjust the gain manually.

Symptom Probable cause Items to check Countermeasures

Loading...

Loading...