16

3.2. Installing Wiring for the Load Cell Input Unit

This section shows the examples of wiring to a load cell.

You can connect the Load Cell Input Unit to a load cell with a 6-wire or 4-wire connection. We

recommend that you use a 6-wire connection for connecting the load cell with the Load Cell

Input Unit to achieve high-precision measurements.

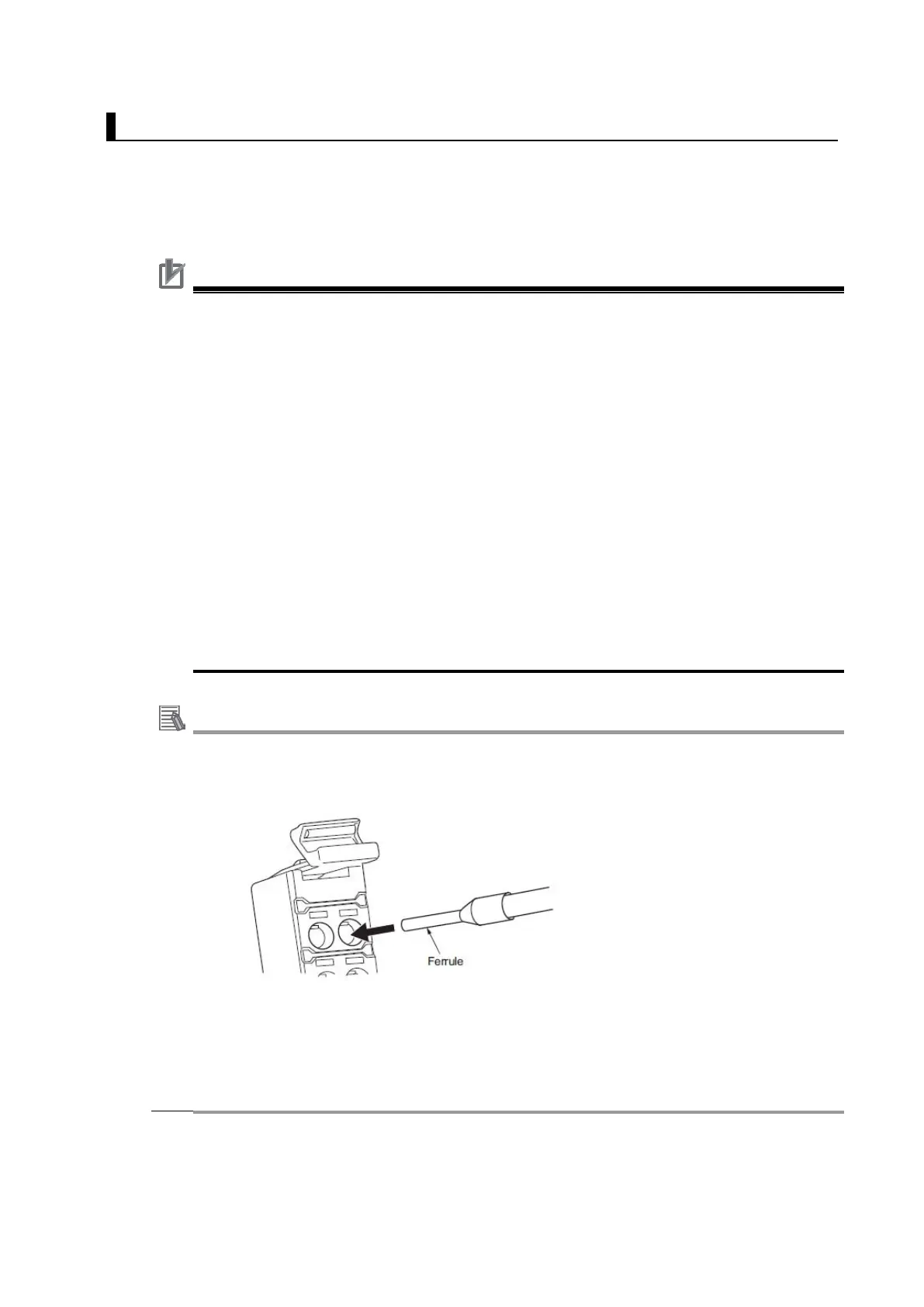

The Load Cell Input Unit uses screwless clamping terminal blocks. The use of

ferrules makes wiring an easy matter of inserting them. The screwless design greatly

reduces wiring work.

The sensor disconnection test is available for the Load Cell Input Unit. Using the

sensor disconnection test after the completion of wiring allows you to check whether

there is a cable disconnection and a non-connected wiring. Refer to the NX-series

Load Cell Input User’s Manual (Cat. No. W565) for details on the sensor

disconnection test.

Precautions for Correct Use

Use a shielded cable to connect to the load cell. Connect the shield wire to the SHLD

terminal on the Load Cell Input Unit.

Ground the functional ground terminal on the Load Cell Input Unit to 100 Ω or less.

We recommend that you use a 6-

wire connection for connecting the load cell with the

Load Cell Input Unit to achieve high-precision measurements. When you use a 4-

connection, the measurement resolution of wiring resistance decreases due to

temperature changes.

Keep the wiring resistance from the load cell to the Load Cell Input Unit to 5 Ω or less

while in use.

Wire the cable that connects the load cell and the Load Cell Input Unit separately from

AC power supply lines or power lines in

order to avoid the effects of the noise. Do not

place such lines in the same duct.

Insert a noise filter into the power supply input section if noise may overlap from

power supply lines when using the same power supply to power an electrical welder

or an electric discharge machine, or there is a high-frequency source nearby.

Loading...

Loading...