Examples and tips

PROGRAMMING MANUAL 268

Revision 1.0

The evident solution is: n = 100 and m = 1224. Or, when we simplify the

factors: n = 25 and m = 306. Therefore: Pn205 = m – 1 = 305. With these

settings, executing MOVE(180) moves the moving part 180 tenths of an

angle degree or 18 angle degrees in forward direction.

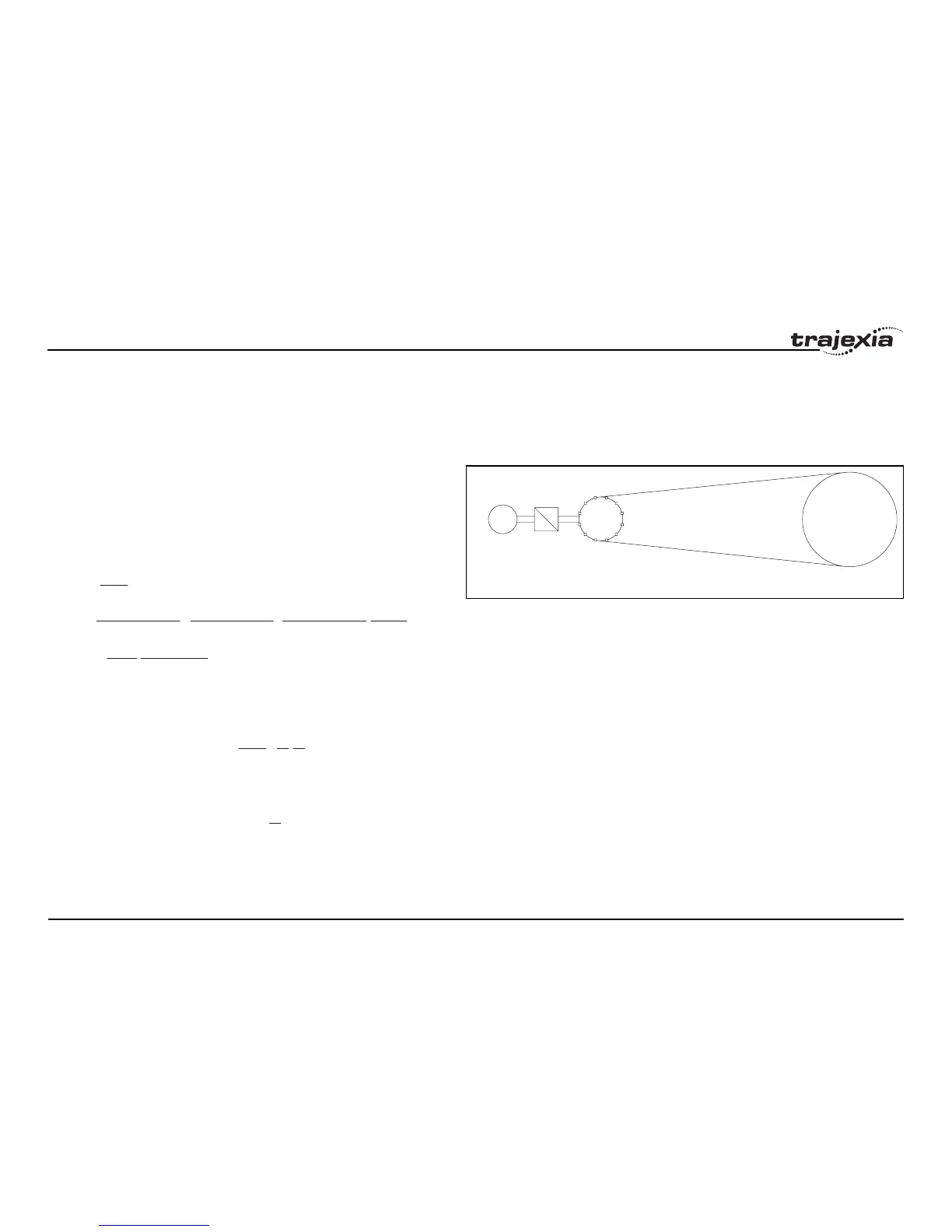

Example 5

fig. 23

The mechanical system uses a servo motor with a 17-bit absolute encoder.

The mechanical gear ratio of the gearbox is 1:10. The pulley has got 12

teeth, and each two are 50 mm apart. One complete turn of the pulley

equals 144 stations on the main wheel. The distance between two stations is

50 mm. The mechanical measurement units must mm. Total repeat distance

must be the distance between two stations, 50mm.

With the same procedure as in example 1, we have:

Therefore, if we use the mechanical system to set the electronic gear ratio,

we have:

One possible solution is:

M

17-bit absolute

encoder

1:10 Gear

Pulley: 12 teeth

50mm between teeth

Main Wheel: 144 stations

50 mm between stations

Pn202

Pn203

UNITS =

2

17

encoder_counts

1 motor_revolution

1 pulley_revolution

10 motor_revolution

12 station

1 pulley_revolution

12 50

2

17

10 encoder_counts

mm

=

50mm

1 station

=

.

.

.

.

.

..

.

.

..

Pn202

Pn203

UNITS

50

2

17

10

=

12

Pn202 = 5

Pn203 = 6

Pn205 = 4

UNITS =

50

2

1

Loading...

Loading...