Examples and tips

PROGRAMMING MANUAL 297

Revision 1.0

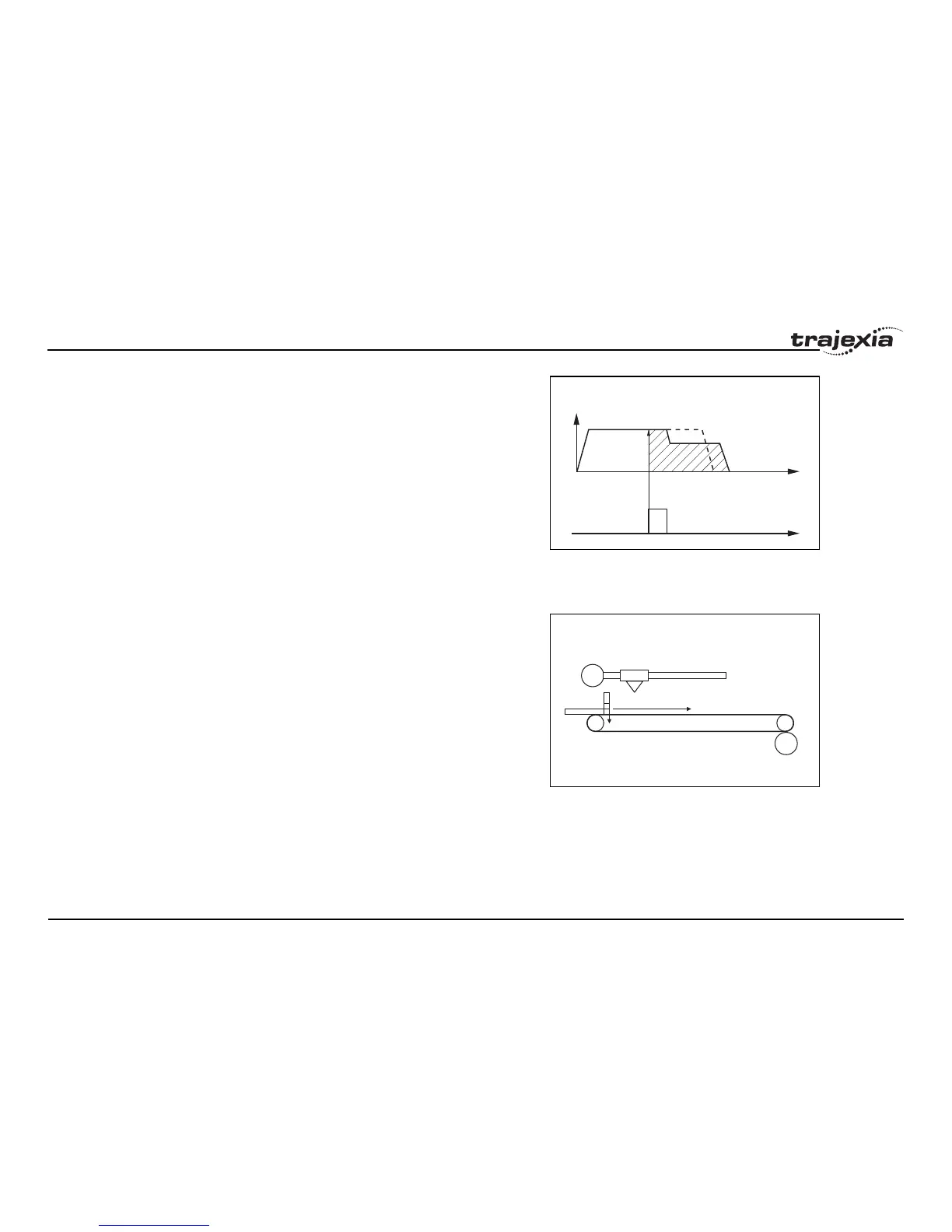

fig. 40

The motion profile and its modification due to the registration mark are

shown in fig. 39.

The BASIC program for this example is:

DEFPOS(0)

REGIST(3) 'Trigger the mark registration

MOVE(bag_length) 'Move to the theoretical distance

WA(1)

WAIT UNTIL MARK OR MTYPE=0

IF MARK THEN

end_position=REG_POS+distance_after_mark

MOVEMODIFY(end_position)

'Correct the distance according to the mark

ENDIF

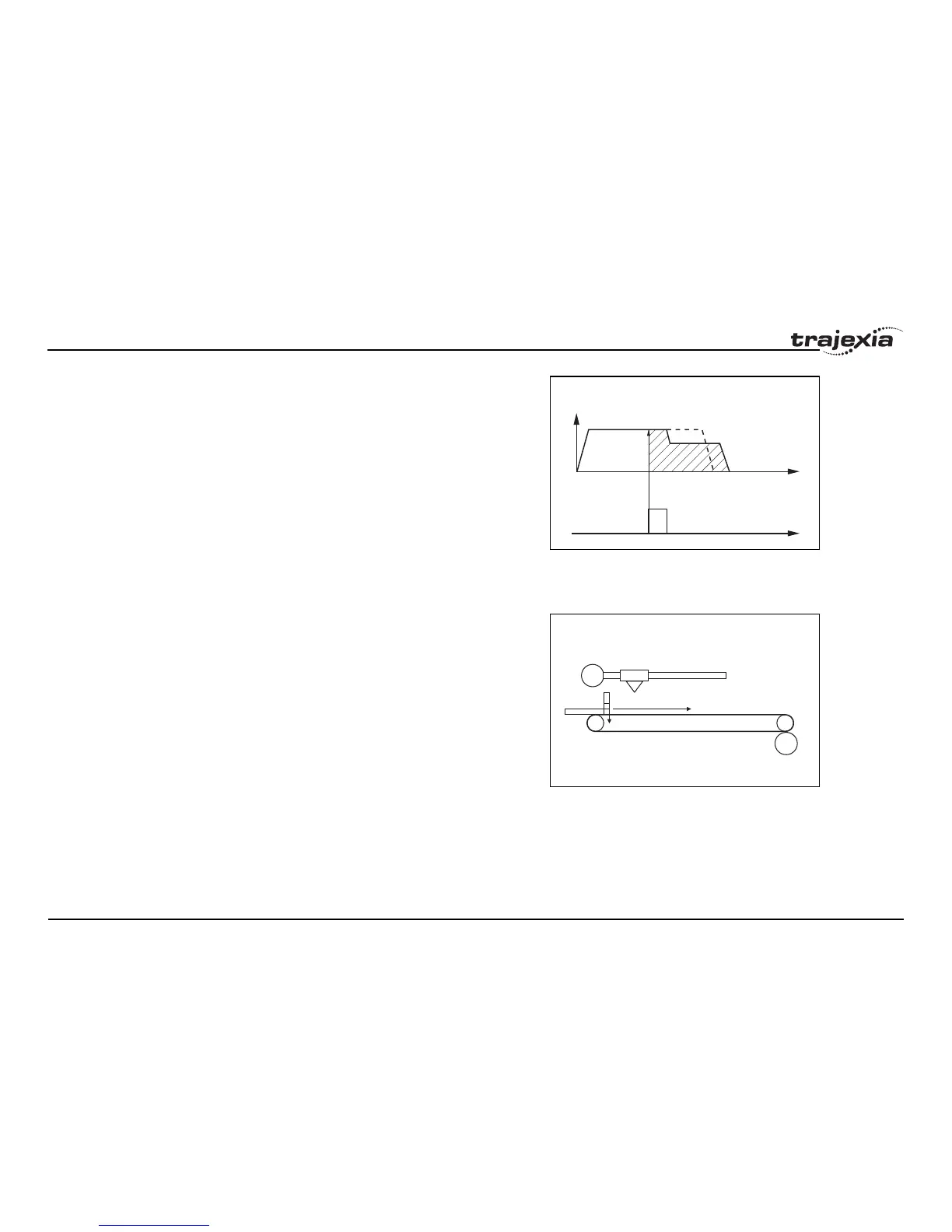

Example: Starting a slave axis in precise position of a master

axis

fig. 41

The picture shows a flying shear cutting the "head" of wood tables. When

the wood comes, the edge of the wood is detected by the photocell and, at

the exact moment, the movement of the flying shear starts to be

synchronized with the right position on the wood.

If the movement is started by the program, upon detecting a signal from the

photocell, there is always at least one SERVO_PERIOD of time of

uncertainty. Instead, the movement is started using the MOVELINK

command with link_option=1, which means that the link to the master axis

starts when the registration event occurs on link (master) axis.

The corresponding program sequence is:

REGIST(2) AXIS(master)

MOVELINK(dst,lnk_dst,lnk_acc,lnk_dec,master,1) AXIS(slave)

For more information on the MOVELINK command and the link_option

argument, refer to section 3.2.196.

t

t

2- The new target position is recalculated:

TARGET POS=CAPTURED POS+"D"

1- The rising edge of

the registration captures

the feeder position

The area below the graph

(distance) is "D"

Feeder

speed

E

E

Master axis

Slave axis

Flying shear

Transporting belt

Loading...

Loading...