6 Programming Features

97

1. Reduce the continuous output current when changing the

carrier frequency to 4 (10 kHz) for 200 V Class (1.5 kW

or more) and 400 V Class Inverters. Refer to the table

above for the reduced current.

Operation Condition

• Input power supply voltage:

3-phase 200 to 230 V (200 V Class)

Single-phase 200 to 240 V (200 V Class)

3-phase 380 to 460 V (400 V Class)

• Ambient temperature:

−10 to 50°C (14 to 122°F)

(Protection structure: open chassis type IP20,

IP00)

−10 to 40°C (14 to 105°F)

(Protection structure: enclosed wall-mounted

type NEMA 1 (TYPE 1))

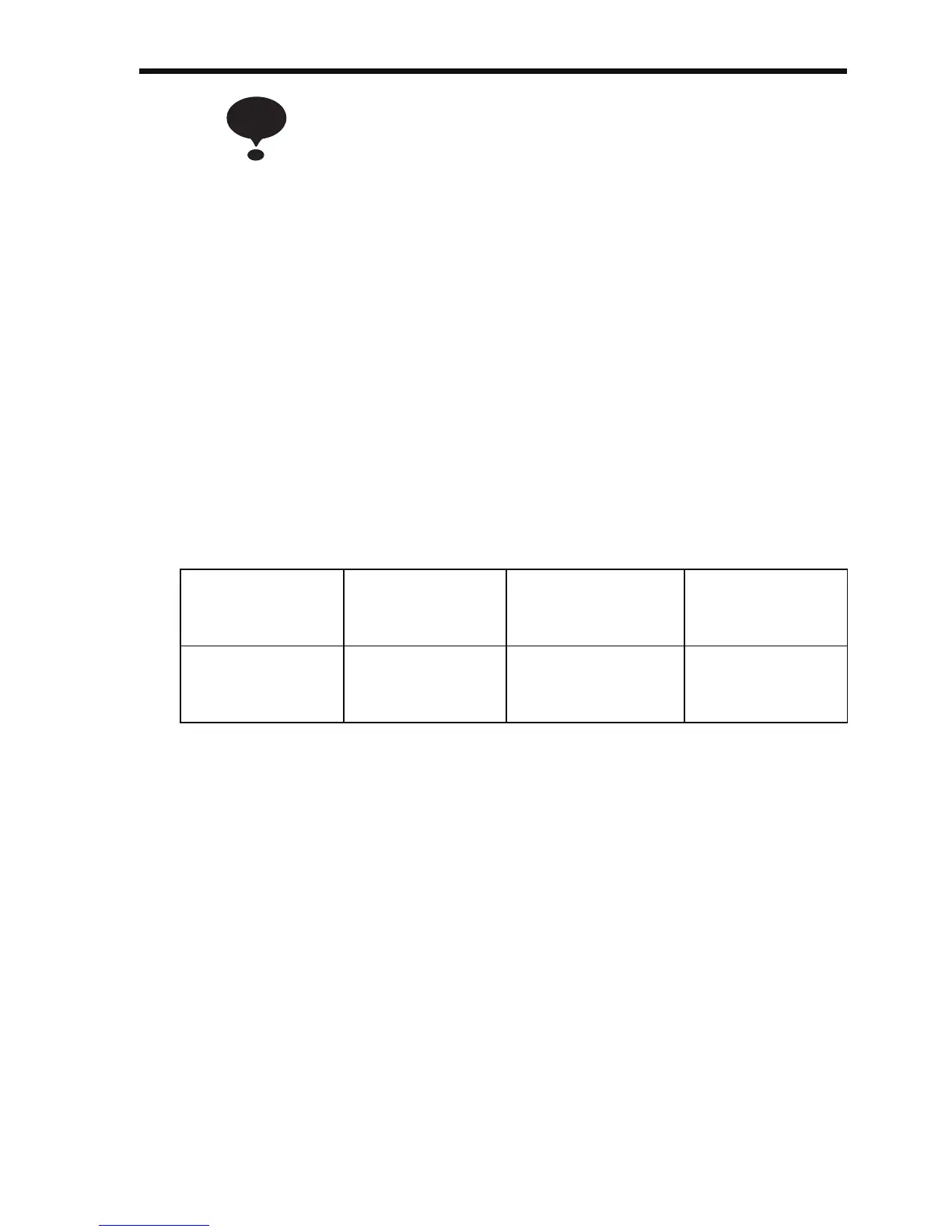

2. If the wiring distance is long, reduce the Inverter carrier

frequency as described below.

3. Set the Carrier Frequency Selection (n080) to 1, 2, 3, or 4

when using vector control mode. Do not set it to 7, 8, or 9.

4. If the Inverter repeatedly stops and starts with a load

exceeding 120% of the Inverter rated current within a

cycle time of 10 minutes or less, reduce carrier frequency

at a low speed. (Set constant n175 to 1.)

5. The carrier frequency is automatically reduced to 2.5 kHz

when the Reducing Carrier Frequency Selection at Low

Speed (n175) is set to 1 and the following conditions are

satisfied:

Output frequency ≤ 5 Hz

Output current ≥ 110%

Factory setting: 0 (Disabled)

Wiring Distance

between Inverter

and Motor

Up to 50 m Up to 100 m More than 100 m

Carrier Fre-

quency (n080

setting)

10 kHz or less

(n080=1, 2, 3, 4,

7, 8, 9)

5 kHz or less

(n080=1, 2, 7, 8, 9)

2.5 kHz or less

(n080=1, 7, 8, 9)

NOTE

Loading...

Loading...