Version 2.1.1 - 2020-07-27 45Translation of original operating manual

Coolant lubricating EN

coolant_GB.fm

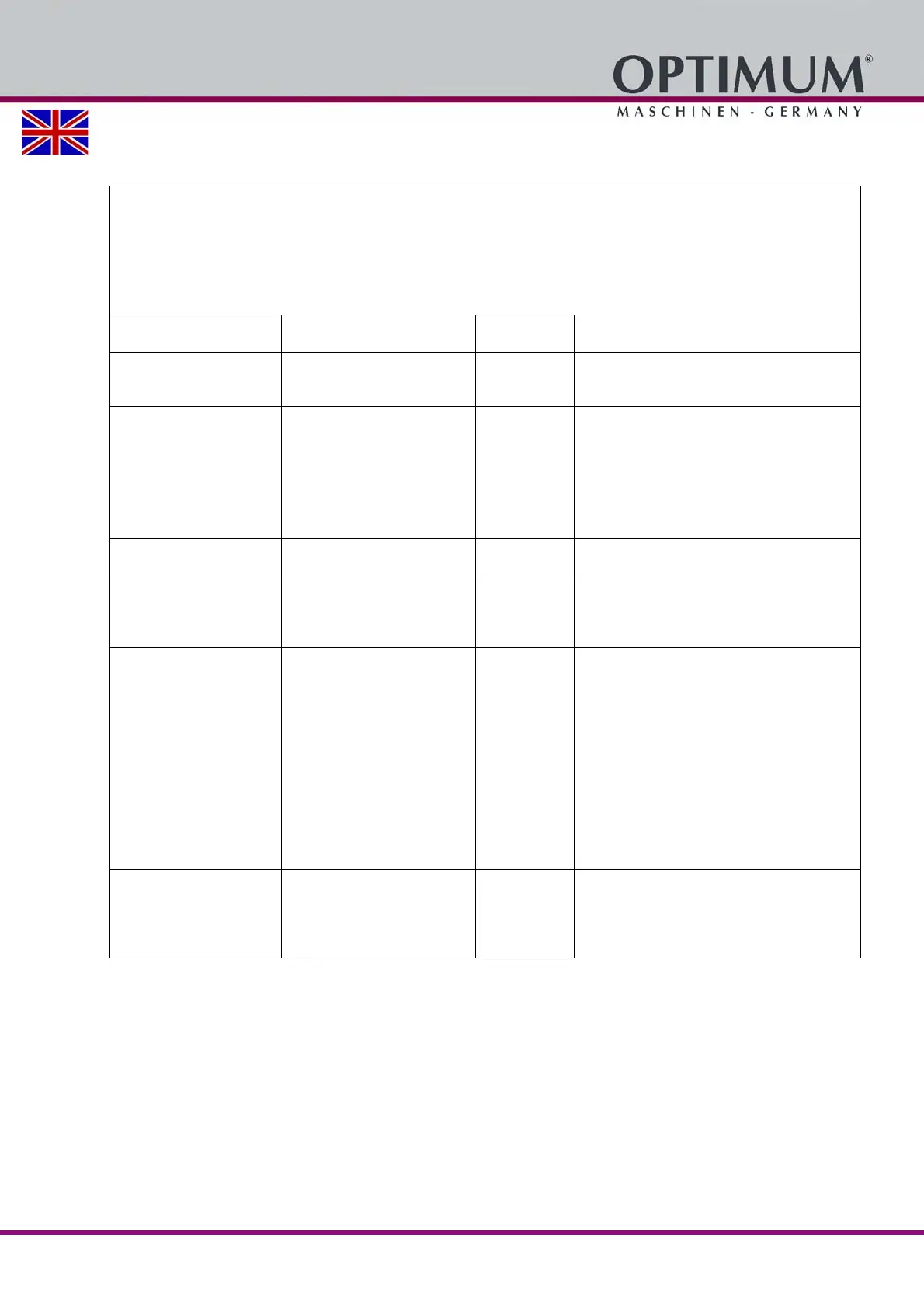

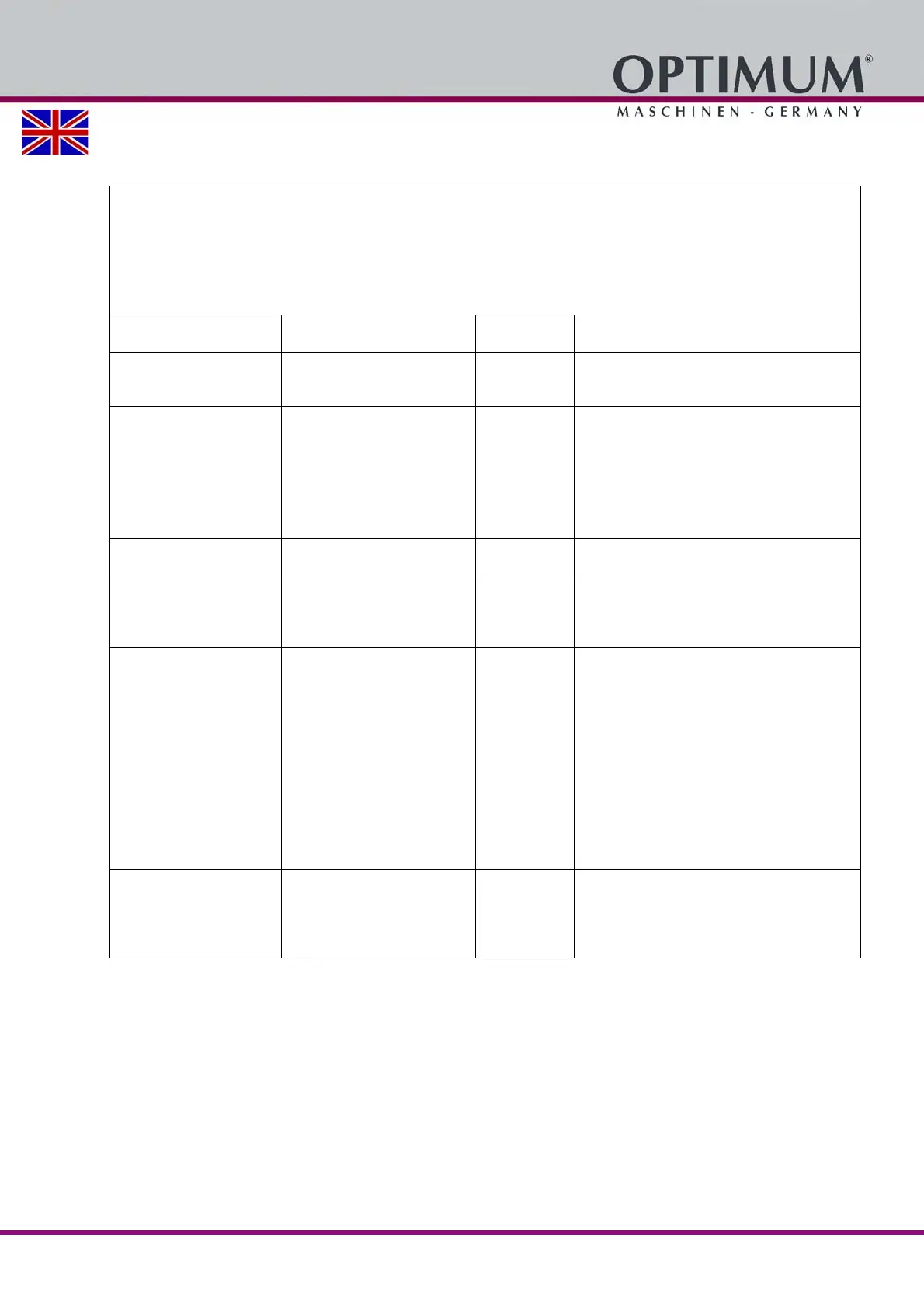

6.4.1 Inspection plan for water-mixed cooling lubricants

1)

The specified inspection intervals (frequency) are based on continuous operation. Other operational

conditions can result in other inspection intervals; exceptions are possible in accordance with Sections 4.4

and 4.10 of the TGS 611.

Editor:

Signature:

Company:

No.:

Date:

used cooling lubricant

size to be checked Inspection methods Inspection

intervals

Procedure and comment

noticeable

changes

Appearance, odour daily Find and rectify causes,

e.g. skim off oil, check filter, ventilate cooling

lubricant system

pH value Laboratory techniques

electrometric with pH meter

(DIN 51369)

Local measurement method:

with pH paper

(Special indicators with

suitable measuring range)

weekly

1)

if pH value decreases

> 0.5 based on initial filing:

Measures in accordance manufacturer's

recommendations

> 1.0 based on initial filing:

Replace cooling lubricant, clean cooling

lubricant circulation system

Usage concentration Manual refractometer

weekly

1)

Method results in incorrect values with tramp

oil content

Base reserve Acid titration in accordance

with

Manufacturer's

recommendation

as required Method is independent of tramp oil content

Nitrite content Test sticks method or

laboratory method

weekly

1)

> 20 mg/L nitrite:

Replace cooling lubricant or part

or inhibiting additives;

otherwise NDELA (N-nitrosodiethanolamine)

in the cooling lubricant system and in the air

must be determined

> 5 mg/L NDELA in the cooling lubricant

system:

Replacement,

clean and disinfect cooling lubricant

circulation system, find nitrite source and, if

possible, rectify.

Nitrate/nitrite content

of the preparation water, if

this is not removed from

the public

grid

Test sticks method or

laboratory method

as required Use water from the public grid if there is

water from the pubic grid has

> 50 mg/l nitrate: Inform the waterworks

Loading...

Loading...