27

ch.3

OrionWelders.com

Keeping the weld time at its max will leave the weld looking smooth and clean.

Using a more technical description – during the welding process the weld spot becomes a liquid

pool of metal. e impact of the welding plasma causes vibrations on the molten pool’s surface,

much like a stone causes ripples on the surface of a still body of water. e Orion welder’s energy

discharge has been designed to ramp down the weld energy for longer weld time. is gives the

molten metal vibrations time to smooth out before the metal re-solidifies. *It is recommended

that the user keep the time at its max length for most welding applications.

In addition, a longer weld time will also help prevent cracking in

some metals as the extended time and longer discharge curve

allows the molten pool to cool more slowly. When the energy

is cut off suddenly (by shortening the time setting) the liquid

metal “freezes” in place. is rapid freezing can cause micro

stresses in the weld spot and may make the metal more prone

to cracks under additional stress (like hammering).

In most cases it is recommended to leave the weld time at max

length with one important exception. If welding a very small

part at less than 5 Ws of energy, it is very helpful to turn down

the time. By turning down the time the arc will still ignite easily

but the energy that the welder allows out during the weld is

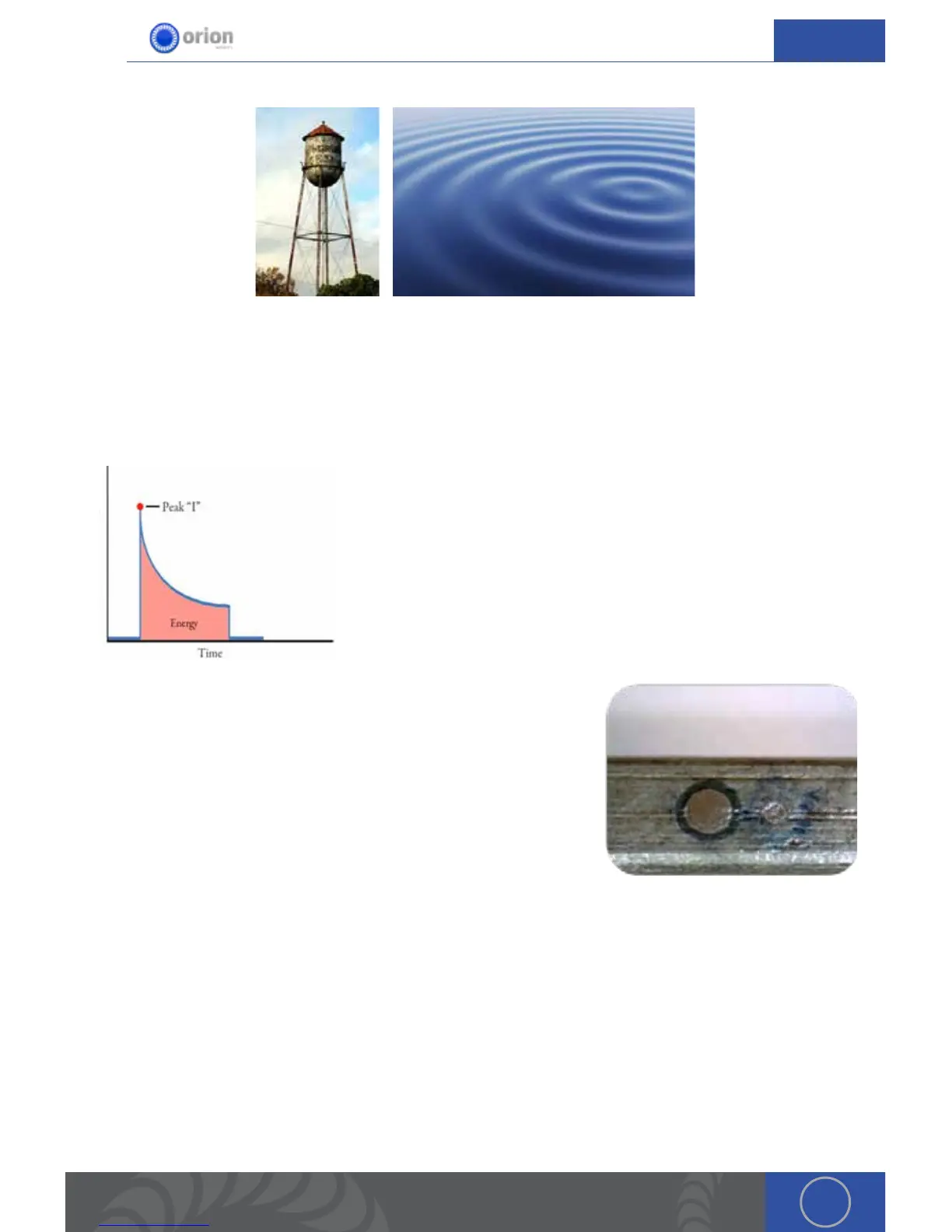

limited by the shorter amount of time. e larger weld in this

image was done at 5 Ws and 15 Ms time. e smaller weld on

the right was done at 5 Ws and 3 Ms time.

Alternatively, the user can sharpen the welding tip to a very fine point to help ignite the

welding arc at very low energy levels.

HANDS ON: Try making a small weld spot using 5 Ws of energy and maximum length, and

then 5 Ws of energy and minimum length. Now, with a very sharp electrode, try making a weld

spot at 1-3 Ws of energy and maximum length.

Loading...

Loading...