100c User Manual

36

ch.5

Symptom Possible Problem Possible Solution

1 Trouble igniting the arc Contaminated electrode Re-grind the electrode to remove con-

tamination

Electrode shape not conducive to

ignition at low energy

Shape the electrode to a very sharp tip

Broken electrode, jagged edges Re-grind electrode to desired shape

2 Cratering of the weld spot Electrode contamination leading to a

metal bridge explosion (see discus-

sion)

Re-grind the electrode

Sharp electrode in a mobile metal

such as silver

Truncate the end of the electrode to help

“un-focus” the weld energy

3 Weld spot not symmetric Damaged or jagged electrode Re-grind electrode

4 Porosity in the work piece Damaged electrode with jagged tips Re-grind electrode

Metal may contain zinc and “boil”

during the welding process. (e.g.

white gold)

Often welding over the same location two

or three times will smooth the weld spot

Sharp electrode in a mobile metal

such as silver

Truncate the end of the electrode to help

“un-focus” the weld energy

1. During the ignition process the electrode is touching the work piece surface when the weld

current begins to flow. e metal contaminate may form a liquid metal electrical conduction

bridge. During the weld ignition process the electrode will retract and this may lead to the

vaporization of the liquid metal bridge as it is necked down during the electrode retraction

process. is vaporization process can be explosive (on a very small scale) and leaves a

crater in the metal’s surface. e result will be a small “pock” mark in the metal’s surface.

e electrode must be reground before reliable welding can continue at this setting. At

lower energies this resurfacing/re-tipping may be very important to get the welder to ignite

reliably. At higher energies the welding process may proceed virtually unhindered even with

a metal contaminated electrode. To remove the small crater, weld over the crater with a

newly ground electrode.

2. e electrode may stick to the metal’s surface. is happens as the liquid metal bridge cools

before the electrode tip has retracted sufficiently to leave the surface of the work piece. A

now solid metal to metal weld has taken place at the electrode tip preventing retraction and

arc ignition. is is often referred to as electrode “sticking”.

3. What can be done if the weld spot doesn’t look good, asymmetric for example? is may

mean the electrode may be damaged (sharp tips or jagged edges or strange shape due to

contamination). Poor tip condition can also lead to porosity (small holes in the work piece).

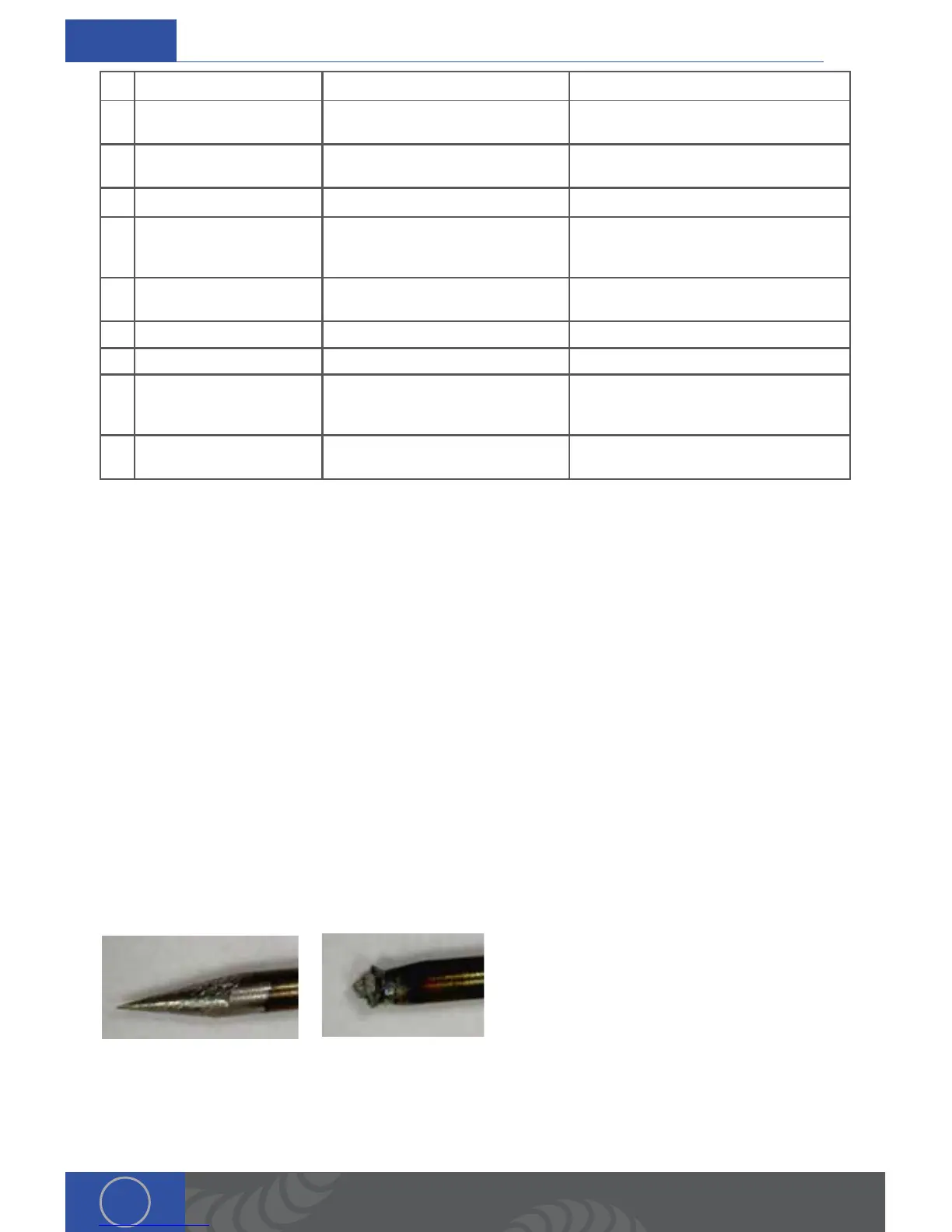

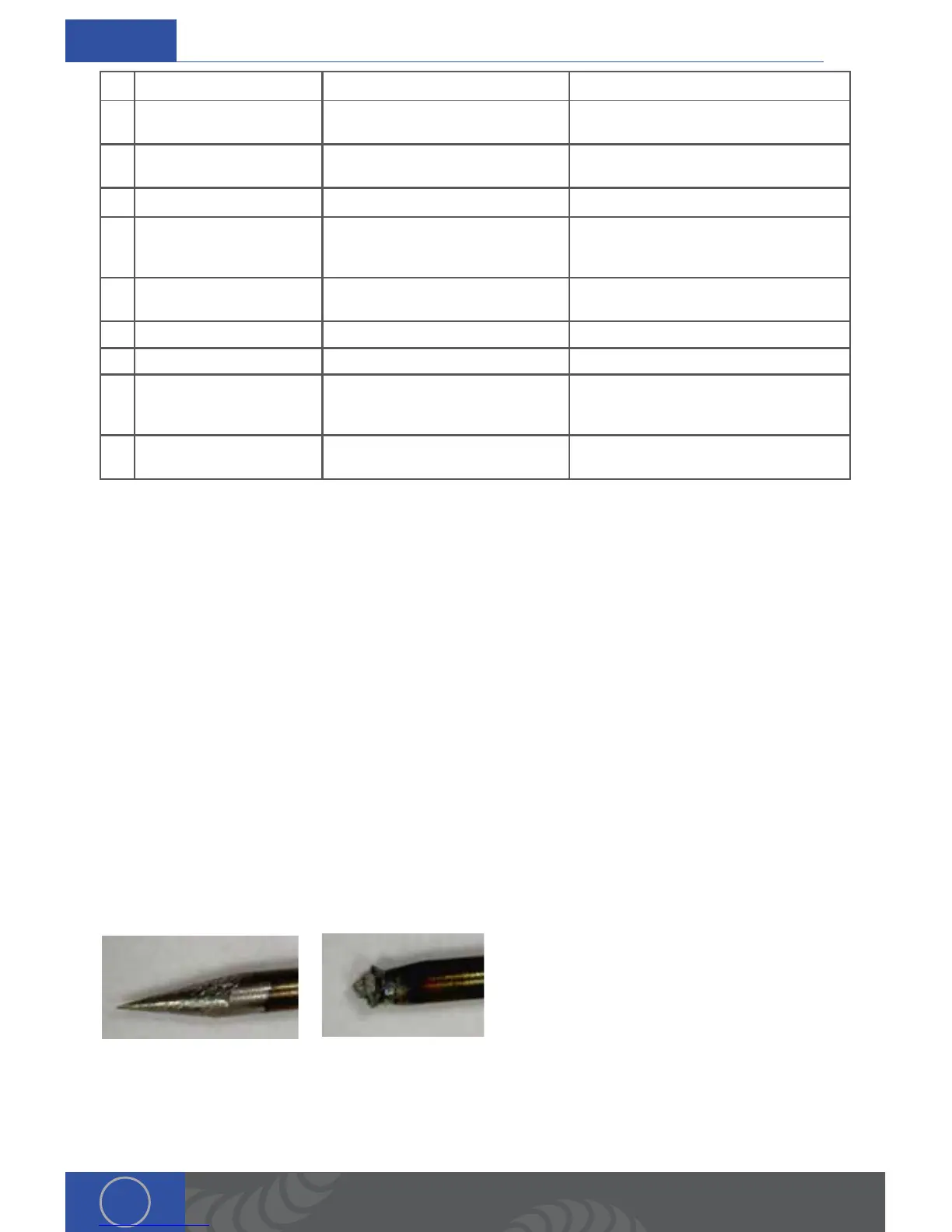

Electrode condition greatly affects energy

transfer and also weld properties (see above

discussions). Left: A perfect electrode. Right:

An electrode in poor condition with metal

contamination.

Loading...

Loading...