6-20

6.6 Troubleshooting

This chapter discusses what is needed to resolve various problems with the printer.

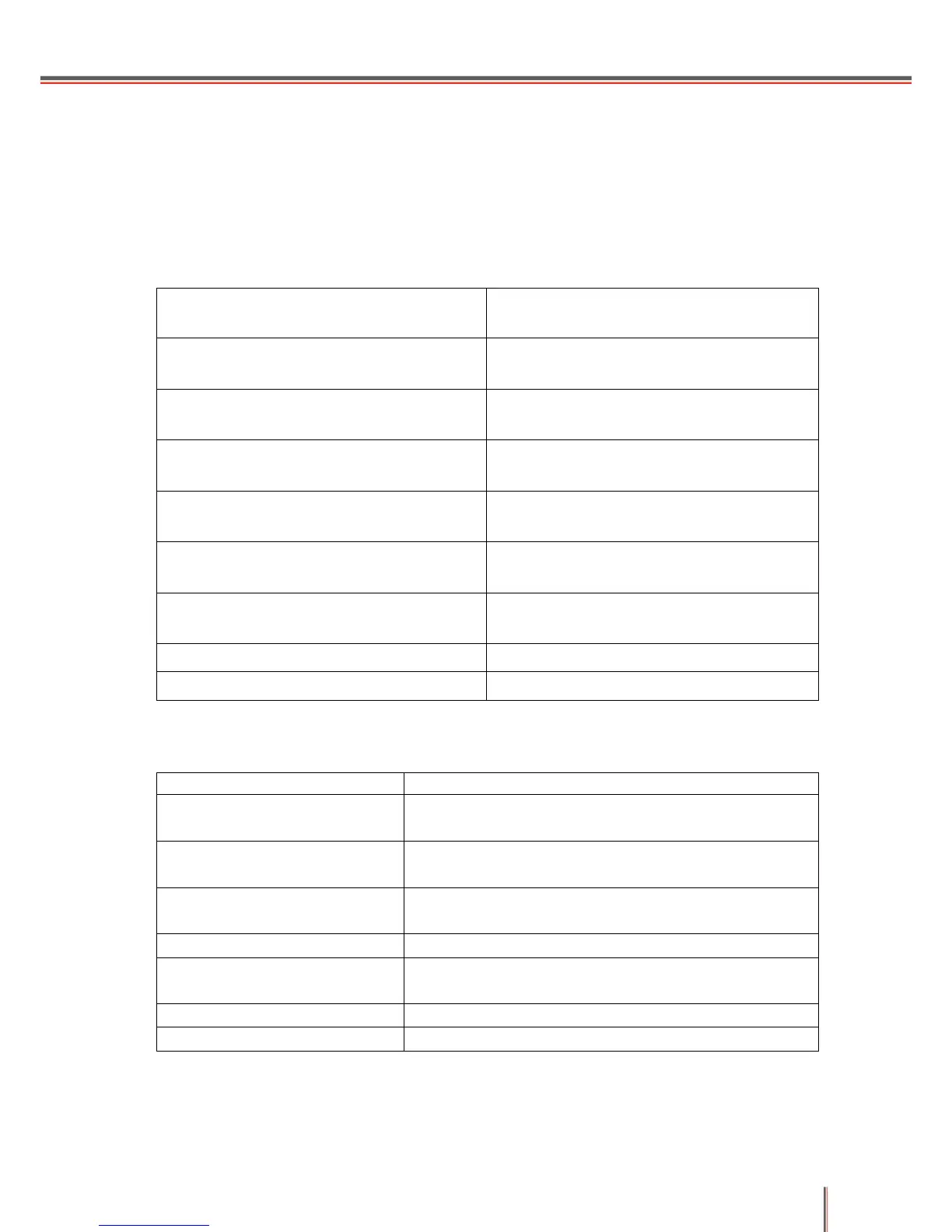

6.6.1 Paper Feed Failure

Initial checking:

Please conduct an initial check when there is a paper feed failure.

Do the print media meet product

specifications?

Is the paper curled, wrinkled, or wet?

Replace the paper and tell users how to

protect the paper.

Is the paper path deformed, dirty, or blocked

up?

Clean the paper path and replace relevant

accessories, if needed.

Is the separation claw dirty, deformed, or

damaged?

Replace the fuser component.

Are the pickup roller and separation

component dirty, deformed or, damaged?

Clean the pickup roller and separation

component, and replace them, if needed.

Are the paper guides correctly placed to

feed paper?

Slide the paper guides closer to the edge of

the paper stack.

Is the clutch gear rotating properly?

Adjust or replace the clutch gear.

Is the electromagnet working properly?

Replace the electromagnet.

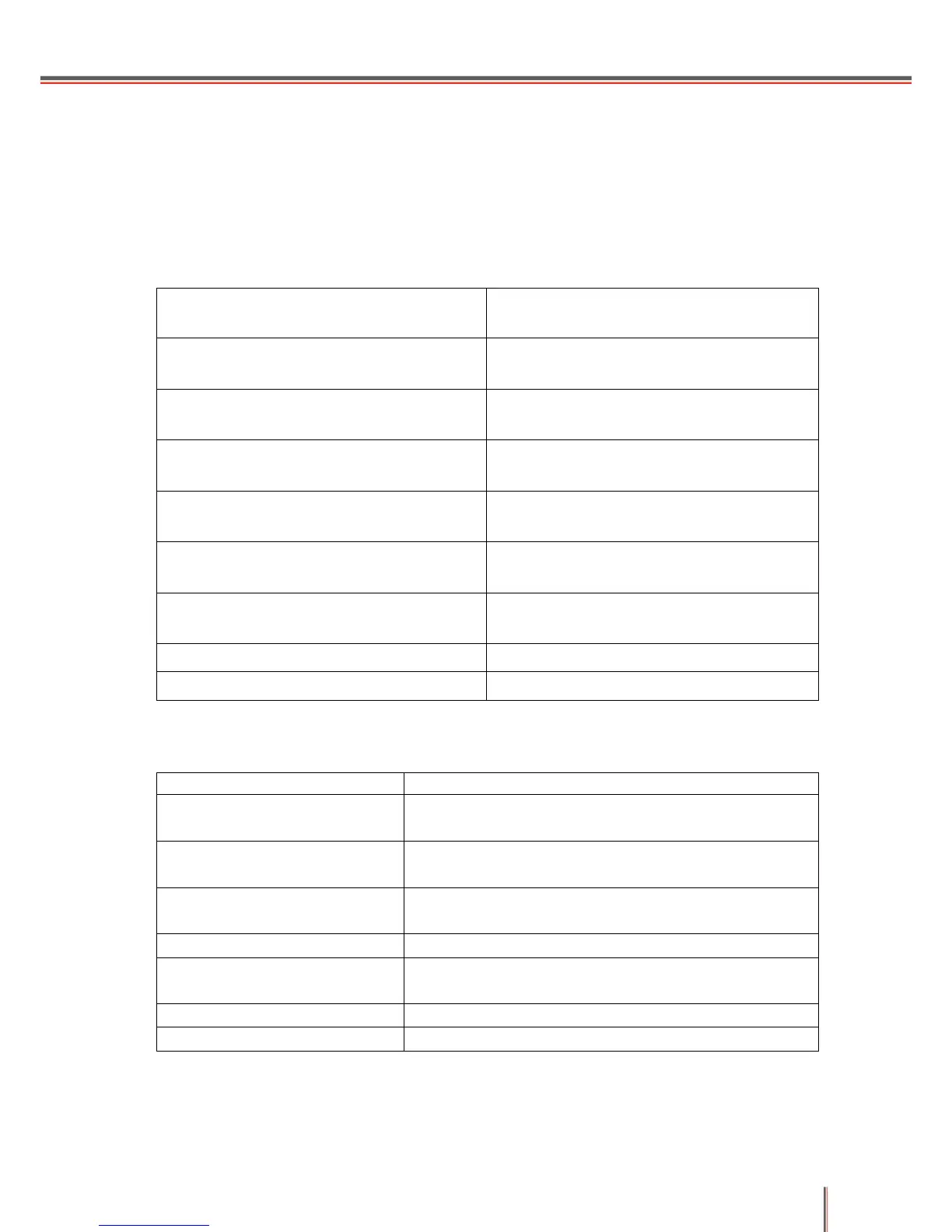

There is no electromagnet

signal.

Check the electromagnet signal input to ensure that

the electromagnet signal line is normal.

The pickup roller or the

separator is contaminated.

Clean the pickup roller and the separator, or

replace them.

The pickup roller or the

separator is worn.

Replace the pickup roller or the separator.

Check the feeder sensor, and clean or replace it.

The tray’s paper-lifting plate

cannot be lifted up.

Check whether the paper-lifting mechanism is

blocked up or damaged.

Replace the engine board.

Loading...

Loading...