GVI Product Manual: Frames C, D & E

16 192-300300N1 GVI Frames C, D & E 2019-9

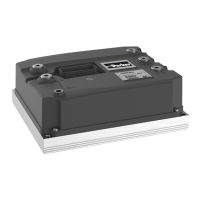

7.3.1. GVI with cold plate heat sink

The motor controller with a cold plate heat sink is cooled through surface contact with the vehicle body.

Specifications for surface roughness and surface flatness where motor controller is mounted to the vehicle

body must be observed (see chapter 13.5.3. Application of thermal grease to the cold plate heat sink before

mounting the motor controller will achieve the best cooling effect.

The required heat sink-to-vehicle mounting surface thermal resistance shown in Table 3 must be achieved

by the installation in order for the motor controller to meet the published current ratings in the application.

For recommendations regarding mounting of the motor controller see chapters 7.5 and 10.5.

GVI-C024-0350, GVI-C024-0550, GVI-C048-0280

GVI-C024-0550, GVI-D048-0450, GVI-D048-0550, GVI-

080-D0230, GVI-D080-0350, GVI-D080-0400

GVI-E048-0700, GVI-E080-0500, GVI-E080-0700

Table 3 Required thermal resistance for flat heat sink

7.4 Orientation

NOTE

The vibration test of the GVI does not include a horizontal mounting position with the I/O

connector facing downwards.

The motor controller can be mounted vertically or horizontally with the I/O connector facing upwards. Care

should be taken to ensure access to the I/O connector, terminals and LED indicator.

When multiple motor controllers are used in an application each of the units must be arranged such that they

have sufficient cooling for the required duty cycle.

Consideration should be given to accessibility and visibility of the on-board LED status indicator (1, Figure 9)

for maintenance purposes.

Figure 9. LED status Indicator, (the surrounding label may vary)

Loading...

Loading...