Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Bulletin HY28-2708-02/SVC/EN | July 2019

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

33

Compensator Disassembly

(C, L & AM B-mod control options)

NOTES:

Access plugs on end of compensator spool bores are hardened plugs.

Do not interchange with other plugs in the control.

For rotation change, the complete compensator assembly will need to

be replaced.

The Pmax spool and inner spring are NOT interchangeable with the load sense or

remote differential spools and springs.

The differential compensator spool and springs are not interchangeable with the main

pressure compensator spool and inner spring. Also, the “L” differential spool is not

interchangeable with the “AM” differential spool.

Compensator Disassembly:

1. Measure and record the extension of the two (only one for “C” control) pressure

adjusting screws.

2. Carefully remove the main compensator (Pmax) spring cap (#9) with outer spring

guide (#6). For “L” and “AM” controls, the Pmax spring cap is the larger of the

two caps. Remove the two springs (#4 & 5). Remove the inner spring guide (#3)

and the Pmax spool (#1) from the compensator housing.

3. For the “L” and “AM” controls, carefully remove the differential compensator

spring cap (#28) with the outer spring guide (#24). The load sense spring cap is

the smaller of the two caps, and the one closer to the top of the controller body.

Remove the inner spring guide (#21) and differential compensator spool (#20) from

the housing.

4. To disassemble the Pmax cap (#9) and outer spring guide (#6) assembly, thread

a long M6 screw through the hole of the Pmax cap to push the outer spring

guide out of the cap.

5. To disassemble the differential cap (#28) and outer spring guide (#24) assembly,

thread a long M6 screw threw the hole of the differential cap to push the outer

spring guide out of the cap.

6. Remove all O-ring boss access plugs (#13 & 18).

7. Remove all internal set screws and plugs (#2, 15, & 16).

NOTE: The compensator is supplied as an assembly. Some individual parts may only

be available in kits. See the controls section of this manual for details.

1. Inspect the main compensator (Pmax) spool (#1) and the differential spool (#20)

for scratches, damage, or contamination particles.

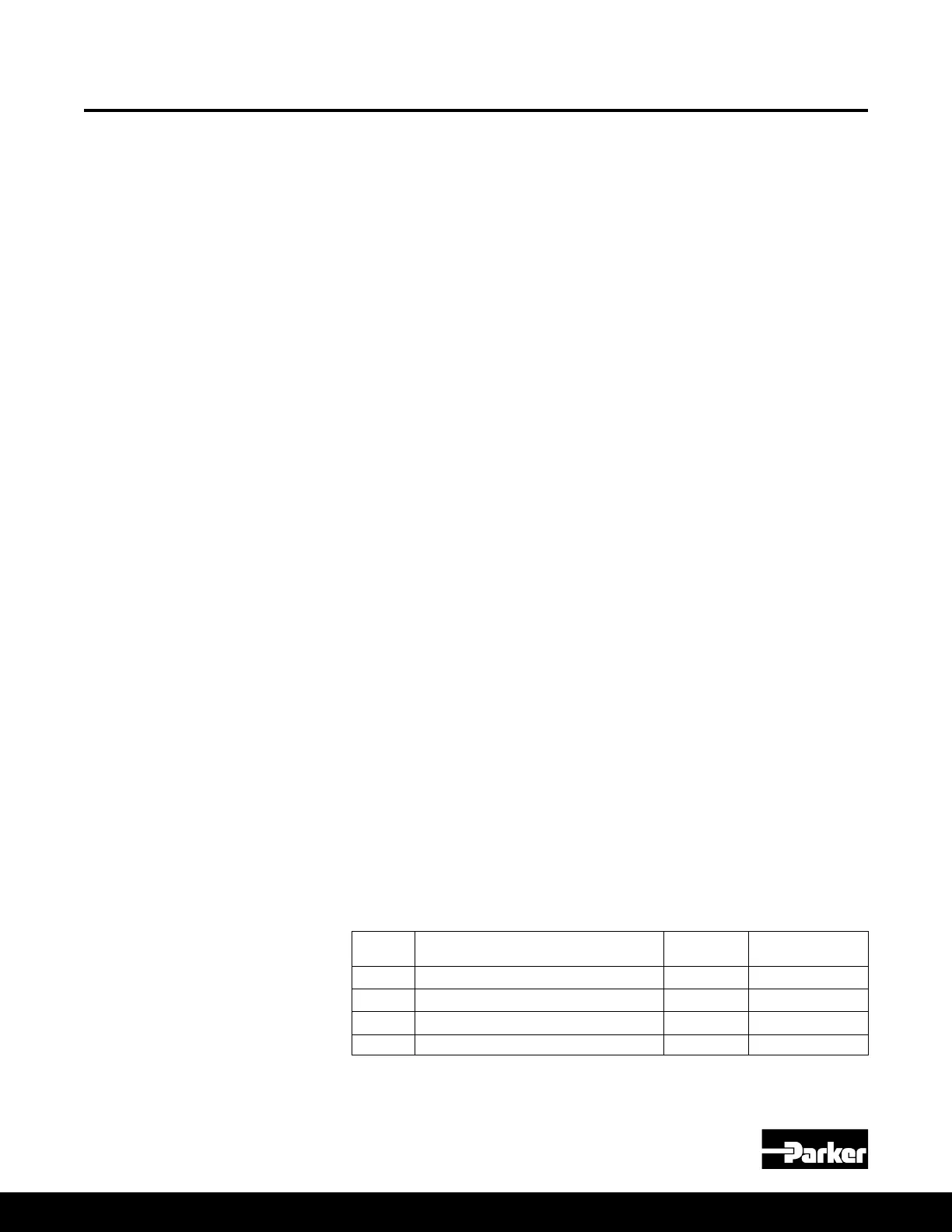

2. Inspect the springs for proper free extension length (see chart).

3. Inspect the spool bores for scratches, damage, or contamination. Apply a light

oil lm on the spool(s) and check their t in the appropriate bore. The spool

should t snugly in the bore and not have any radial play.

4. Inspect orices for any contamination particles that may be blocking the orice.

Compensator Inspection

Item No Component Description

Free Length

[mm]

Tolerance Ref. ±

[mm]

4 Pmax Inner Spring 28.85 0.66

5 Pmax Outer Spring 35 0.66

22 Differential Inner Spring 14.9 0.66

23 Differential Outer Spring 21 0.66

Reference item numbers on page 13-16.

Table 1 - P1/PD B-Mod C, L, & AM Compensator Free Spring Length

Compensator Procedures

Loading...

Loading...