Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Bulletin HY28-2708-02/SVC/EN | July 2019

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

45

11. If the barrel hold down spring (#21) was removed, place the barrel (#23) on

xture with pin side down and install the back-up washer (#22) and hold

down spring. Compress the spring in a press and install the snap ring (#20).

Next, rotate the barrel assembly so that the piston bores face up. Place the

three barrel pins (#24) into the three slots in the barrel spline as shown in

Figure 3. Petroleum jelly can be used to hold the pins in place while installing

the remaining parts.

CAUTION: Make sure the snap ring (#20) is properly seated in the groove

prior to removing the barrel (#23) from the press.

12. Apply a light oil lm into the piston bores of the barrel (#23). Lightly lubricate

the spherical surface of the spherical retaining plate washer (#25). Install

the nine piston bores down (#27) into the bores in the retaining plate (#26).

Assemble the spherical retaining plate washer into the retaining plate.

While holding the spherical washer against the retaining plate, slide the

pistons into the barrel.

13. Install the port block locating/dowel pin (#7) into the port block (#3) face.

14. Install the port block control ow set screw (#6) in the proper location

depending on pump rotation. For proper location, see Figure 11 in the

rotation change section. The set screw should be installed in the passage

on the same side of the port block as the control piston.

15. Install unlubricated O-rings (#10) onto the control piston guide (#14) and

bias guide (#11). Apply Loctite Primer SF 194500 to the control piston guide

and bias guide threads and allow it to dry. This usually take about three

minutes. Apply Loctite 263 to the guide threads. For CW rotation, install the

control piston guide (#14) nearest to the locating pin. See Figure 10A.

For CCW rotation, install the bias guide (#11) nearest to the locating pin (#7).

See Figure 10B. Torque the guides per the values specied in the Table 4.

Table 5

Pump

Control and Bias Guide

Torque

060

105 ± 5 ft-lbs

(142 ± 6.5 Nm)

075 /085

105 ± 5 ft-lbs

(142 ± 6.5 Nm)

100

136 ± 6 ft-lbs

(184 ± 8 Nm)

140

170 ± 6 ft-lbs

(203 ± 8 Nm)

16. Apply a light oil lm to the control piston (#15), and install it into the control

guide (#14) bore. Apply a light oil lm to the bias piston (#12). Install the bias

spring (#13) over the bias guide (#11) bore, and then slide the bias piston into

the bias guide bore.

17. Install the control ow housing set screw (#34) into the proper passage.

For proper location, see Figure 12 in the rotation change section.

18. Apply a light layer of petroleum jelly to the back surface of the port plate (#9)

and place it on the port block (#3), lining up the slot on the port plate with the

locating pin (#7). See Figure 7.

13. Apply a light film of oil into the piston bores. Lightly lubricate the spherical

surface of the guide ball. Install the nine pistons into the bores in the hold

down plate. Install the spherical guide ball into the hold down plate. While

holding the guide ball against the hold down plate, install the pistons into the

barrel.

14. Install the locating pin on the port block face.

15. Apply Loctite Primer Grade T to guide threads and allow to dry. Install

unlubricated o-rings on the control guide and bias guide. Apply Loctite 271to

guide threads. For left hand rotation the bias guide is installed nearest to the

dowel pin (figure 5A.) For right hand rotation the control guide is installed

nearest to the dowel pin (figure 5B.) Torque the control and bias guides as

16. Apply light oil film to control piston and install it in the control guide bore.

NOTE: The 140 had a lubrication hole in the piston. Confirm that the hole is

facing the port block. The control guide has nonsymmetrical lubrication

grooves. The end with the closest grooves must be installed towards the

port block.

17

. Apply light oil film to the bias piston. Install the bias spring and the bias

piston in the bias piston guide bore.

18. Apply a light layer of petroleum jelly to the back surface of the port plate.

Install the port plate on the port block, lining up the slot on the port plate with

the locating pin.

19. Install the large o-ring in the groove on the pump housing. Install the three

Teflon o-rings in the pressure communication ports on the pump housing.

20. Install the cam bearings in the cradle area of the housing. The chamfer on

the back of the bearing must face the outer wall of the housing. Use Loctite

Primer Grade “T” or other suitable primer on screws and mating threads in

housing. Apply Loctite #242 (use sparingly) to screw threads and install

orifice screws to hold bearings in place. Torque screws to 3.4 0.25 Nm (33

3 in-lb).

21. Place thin film of clean oil on cam bearing surfaces. Install cam in housing.

The cam must be tilted to permit entry into the housing. (Figure 2) NOTE:

The large pocket on the bottom surface of the cam must be on the same

side as the three pressure communication holes on the main housing. Pump

rotation does not affect the assembly of the cam.

22. Install the drive shaft into the pump housing. Position pump horizontally.

Install the rotating group over the pump shaft. Rotate the barrel to insure that

it is seated against the cam. Insure that the pump shaft is seated properly in

the front bearing.

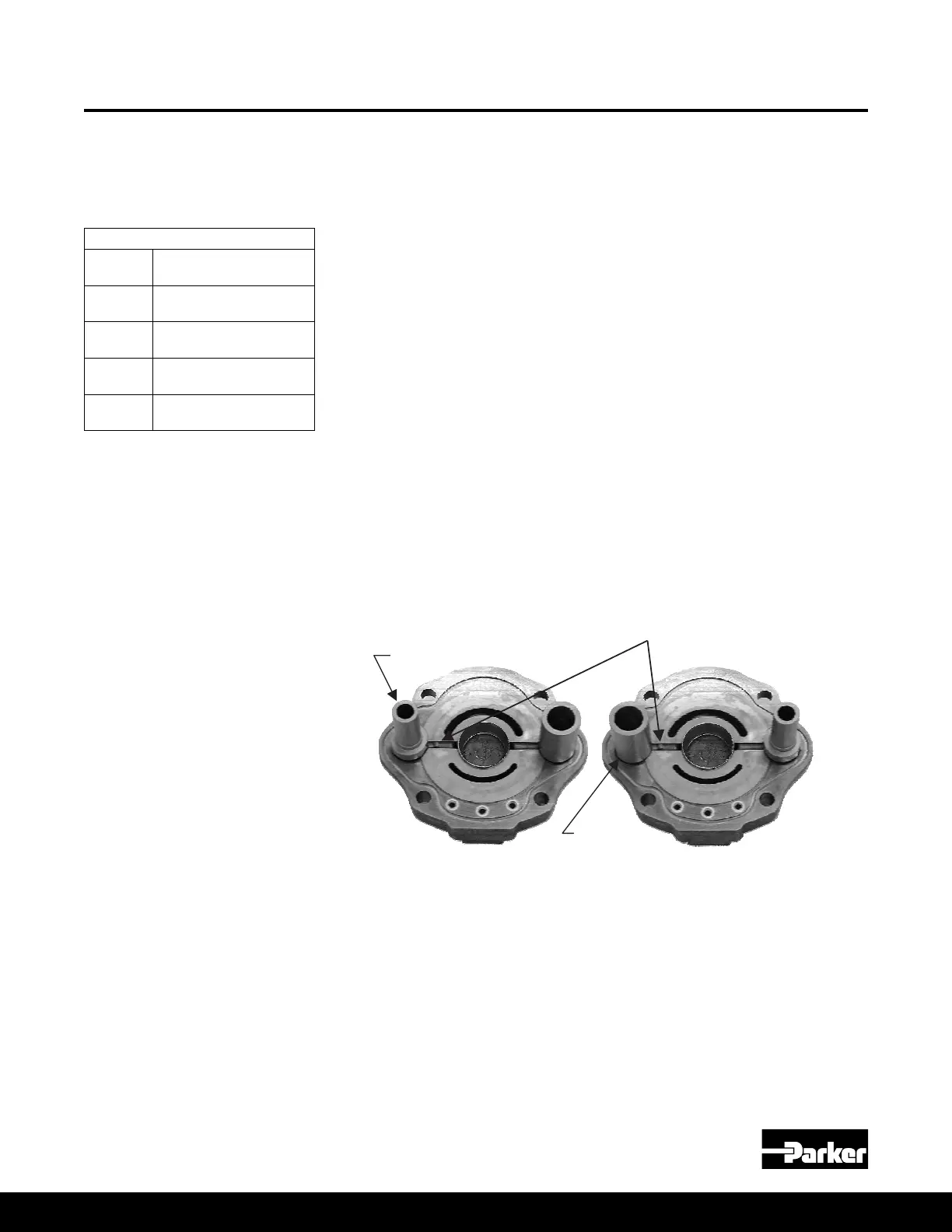

Figure 5A

Port Block with Left

Hand Configuration

Figure 5B

Port Block with Right

Hand Configuration

specified in Chart 3.

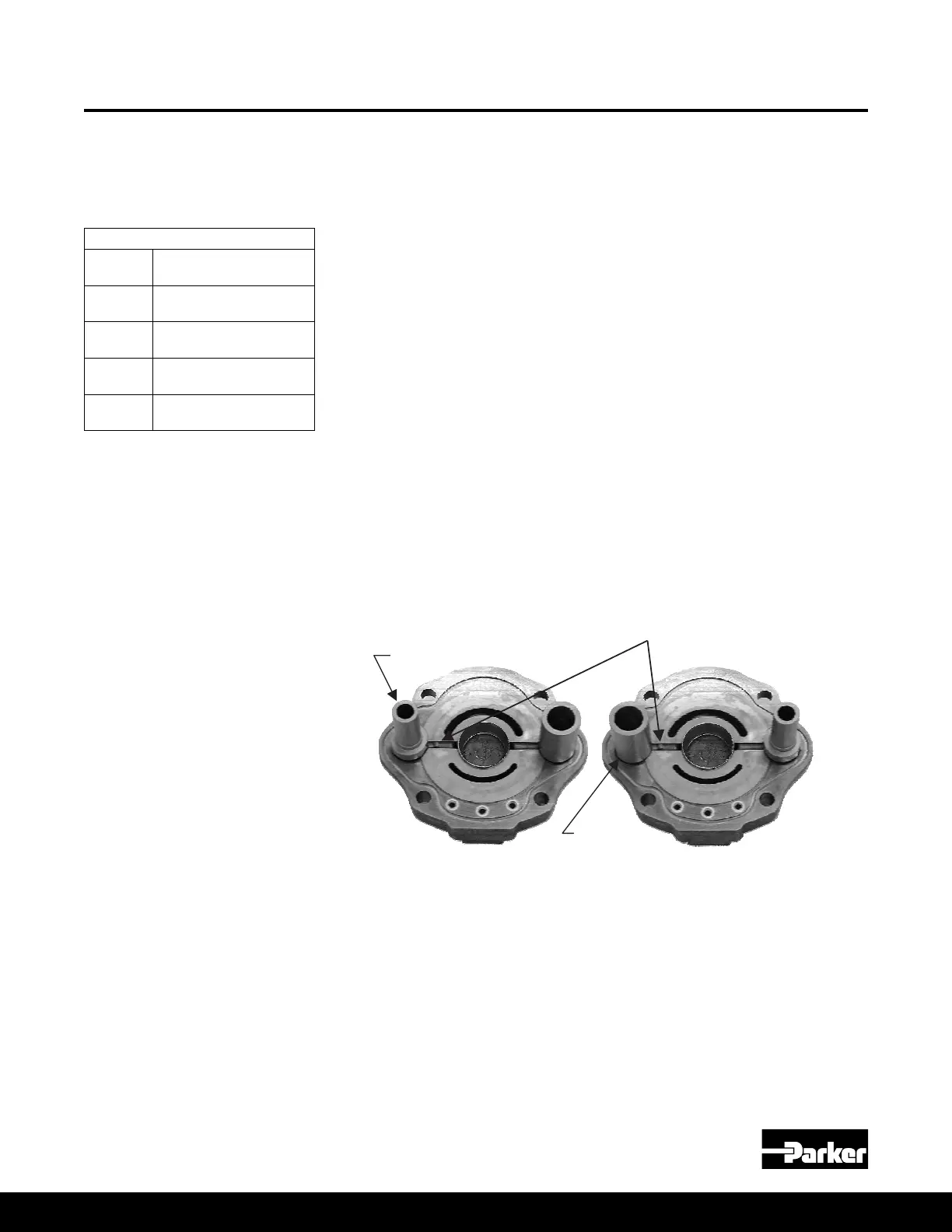

Locating Pin

Bias Piston

Guide

Control Piston

Guide

Chart 3

Pump Control and bias

guide torque

045

Figure 10A

Port Block with Left

Hand Conguration

Figure 10B

Port Block with Right

Hand Conguration

Pump Assembly Procedures

(Continued)

060, 075, 085, 100, 140 Assembly Procedures

Loading...

Loading...