Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Bulletin HY28-2708-02/SVC/EN | July 2019

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

39

ASSEMBLY PROCEDURE

CONTINUED 9. Repeat the procedure three times. Once recorded, take the average of the

three measurements.

10. With the average, use chart 2 to determine the correct shim to install in the

pump.

11. If barrel hold down spring was removed during disassembly process, install

three pins to slots in barrel spline. Petroleum jelly can be used to hold pins in

place while installing remaining parts. (Figure 4) Place barrel on fixture with

pin side down. Install backup washer and hold down spring. Compress

spring in press and install snap ring. Caution: Make sure snap ring is

properly seated in groove prior to removing barrel from press.

Figure 4

CHART 2

mihSlaitnereffid derusaeM

minimum maximum thickness 018 part # 028 part # 045 part #

Any seals removed during disassembly, including the shaft seal, should be

replaced. For major overhauls, all plugs should be removed and their O-rings

replaced.

Assembly should be performed in a clean work environment.

Do not use bearing grease during installation. Grease does not dissolve in

hydraulic oil and may plug orices or lters in the system. Clean petroleum jelly

is preferred to lubricate O-rings and seals and to adhere parts for assembly.

NOTE: For uids other than petroleum based hydraulic oil, ensure that the

petroleum jelly is compatible with the uid. If not compatible, another product

should be used instead.

1. Make sure new parts are clean, or if re-using parts, make sure they are

thoroughly cleaned.

2. Inspect all bearing surfaces and seal areas to ensure that they are free from

nicks, dings, scratches, or rust.

3. For the 45cc pump, skip step 3. For the 18 and 28cc pumps, turn the housing

over. Use installation tool T1 and press the shaft seal (#39) in the seal bore.

Install the snap ring (#40) into the groove in the housing seal bore.

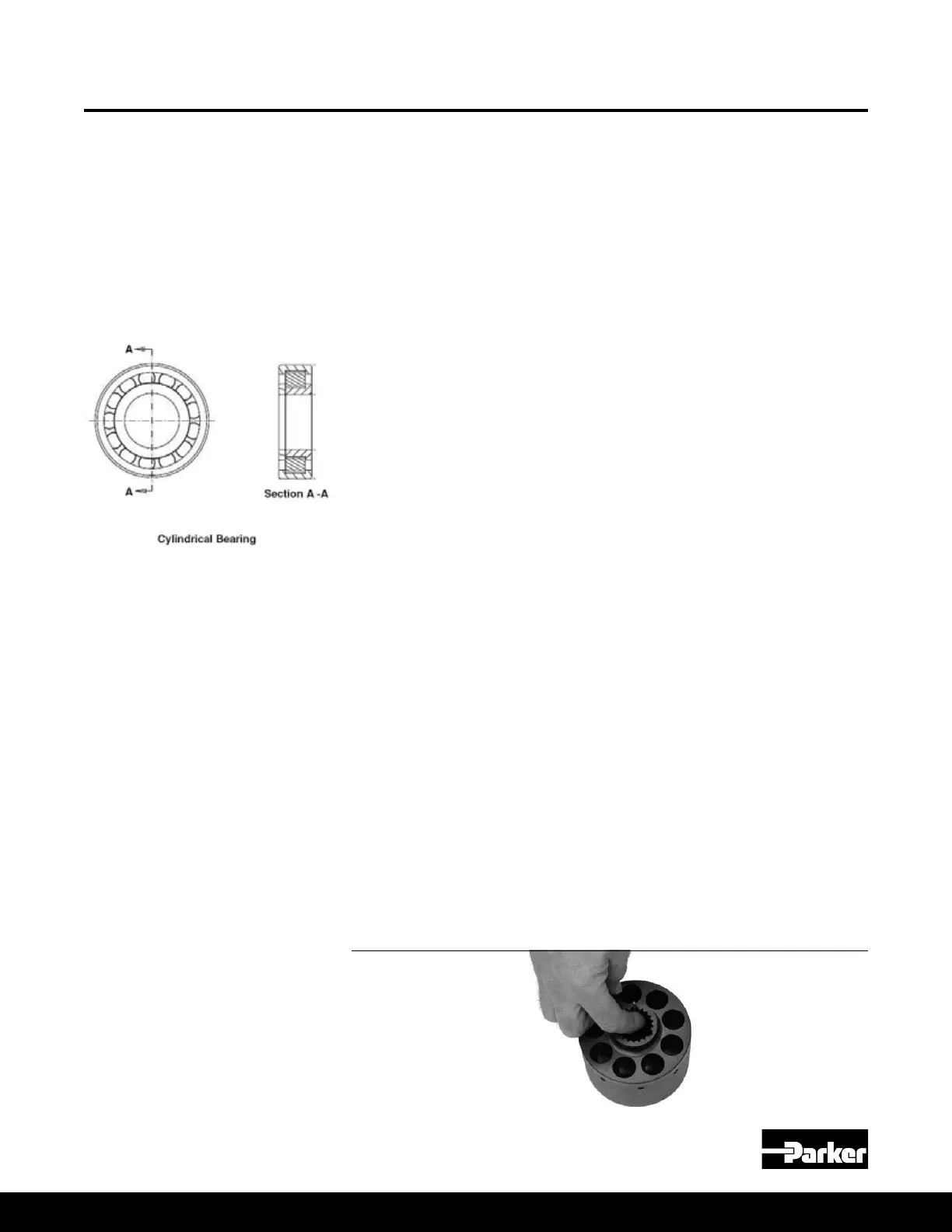

4. Install the cylindrical shaft bearing (#32) onto the pump shaft (#28). It is a slip

t for the 18 and 28cc pumps. For the 45cc pump, use tool T2 to install the

shaft bearing onto the pump shaft.

5. Install the external retaining ring (#42) to secure the bearing in place on the

shaft. For the 45cc pump, use tool T3 to install the shaft seal (#39) over the

shaft. Tool T3 will help protect the shaft seal from being damaged by the

splines during shaft installation. For all three sizes, insert the shaft assembly

into the pump housing with the bearing sliding into the bearing diameter in

the housing. Be sure not to cut or damage the shaft seal while installing the

shaft. For the 28cc pump, tool T3 can be used to protect the shaft seal from

damage from the splines of the shaft. For the 18 and 28cc pumps, install the

internal retaining ring (#43) into the housing. For the 45cc pump, install the

shaft seal snap ring (#40) into the groove in the housing seal bore.

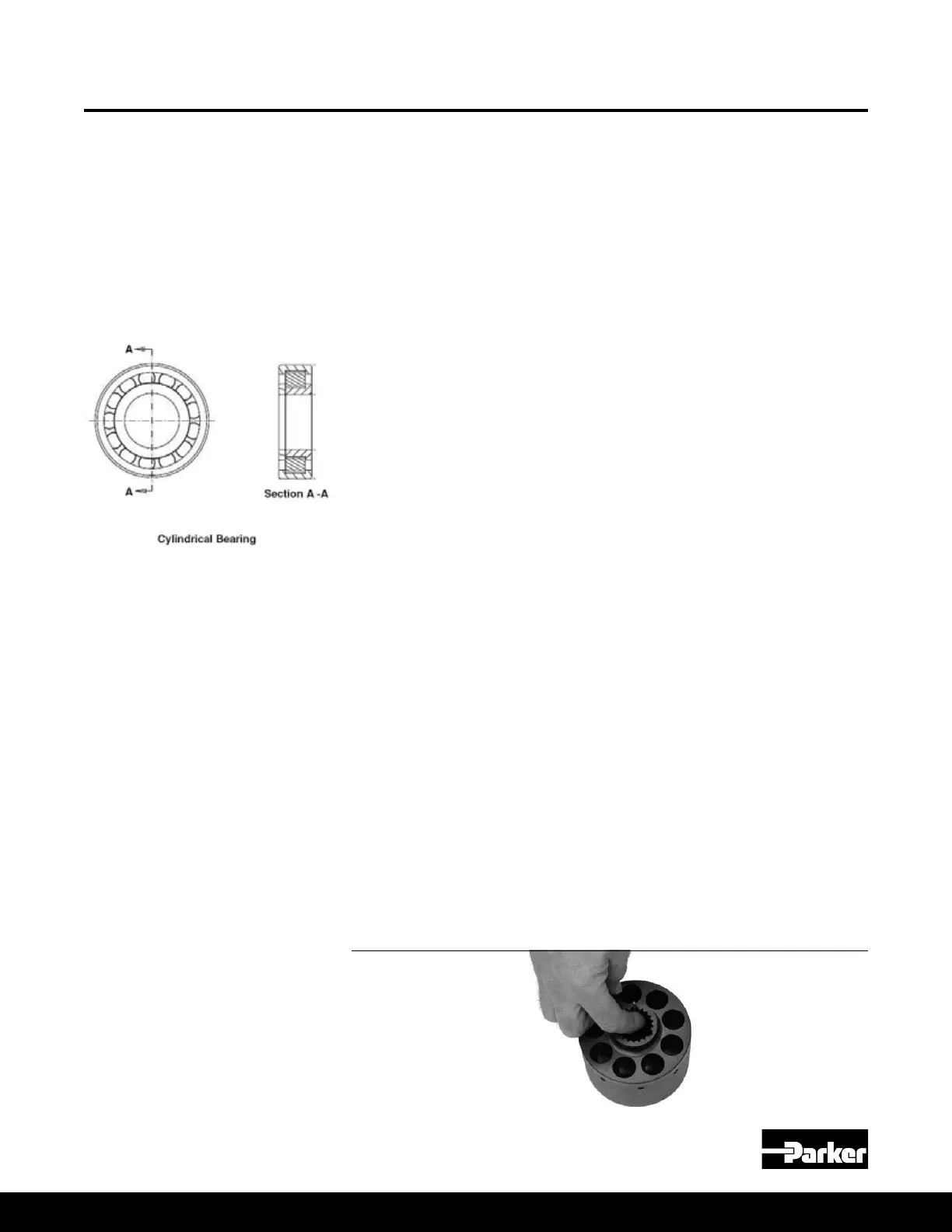

6. If the barrel hold down spring (#21) was removed during the disassembly

process, place the barrel (#23) on xture with piston bores down. Install the

back-up washer (#22), hold down spring (#21), and second back-up washer

(#22). On the 45cc pump and larger, there is only one back-up washer (#22).

Compress the spring in a press and install the snap ring (#20). Next, rotate

the barrel assembly so that the piston bores face up. Slide tool T6 up through

the center of the barrel from the bottom side. Place the three barrel pins (#24)

into the three slots in the barrel spline as shown in Figure 3. In lieu of tool

T6, petroleum jelly can be used to hold the pins in place while installing the

remaining parts.

Pump Assembly Procedures

Figure 3

CAUTION: Make sure the snap ring (#20) is properly seated in its groove prior to

removing the barrel assembly from the press.

018, 028, 045 Assembly Procedures

Loading...

Loading...