Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Bulletin HY28-2708-02/SVC/EN | July 2019

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

56

Component problems and circuit problems are often interrelated. An improper circuit may operate with apparent success but

will cause failure of a particular component within it. The component failure can be the effect, not the cause of the problem.

This general guide is offered to help in locating and eliminating the cause of problems by studying their effects.

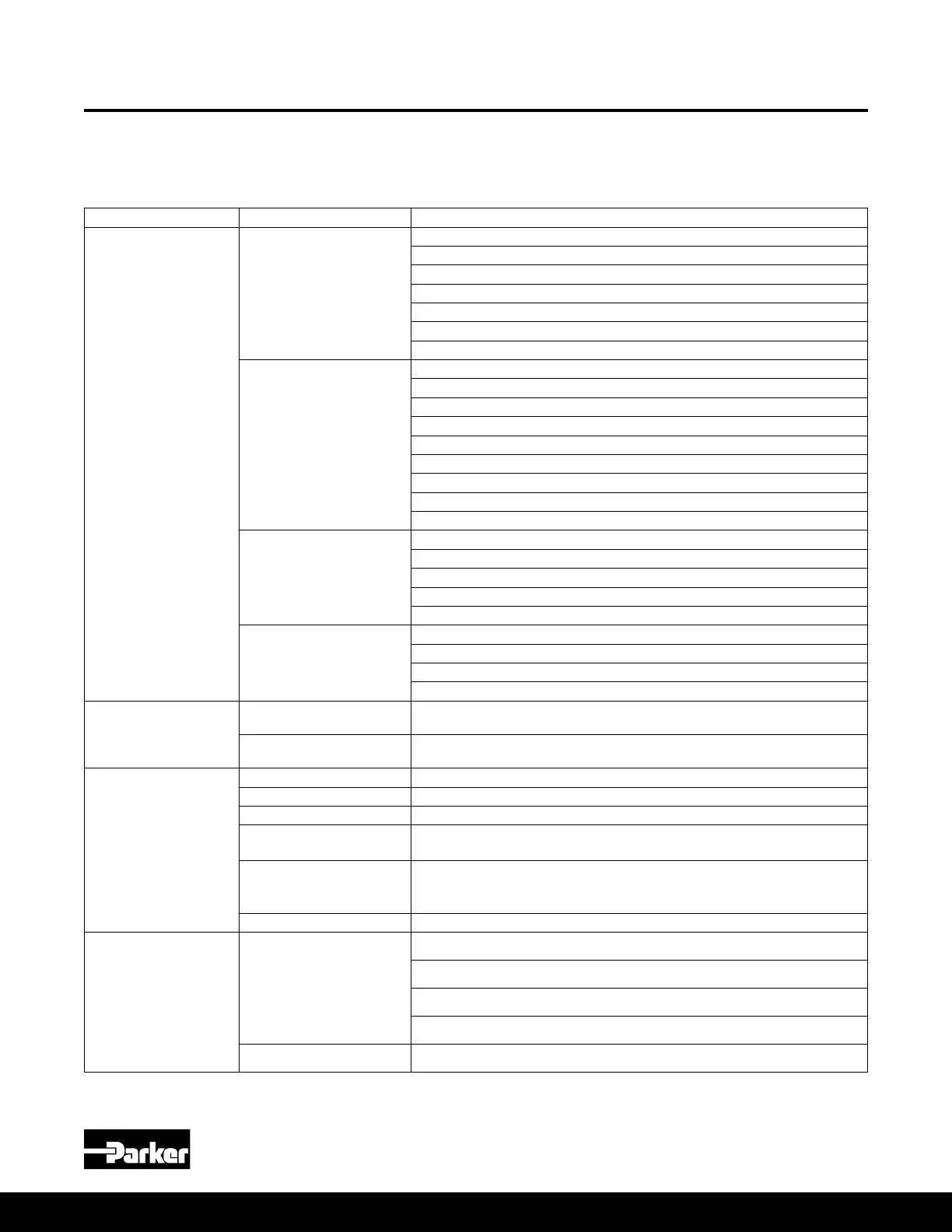

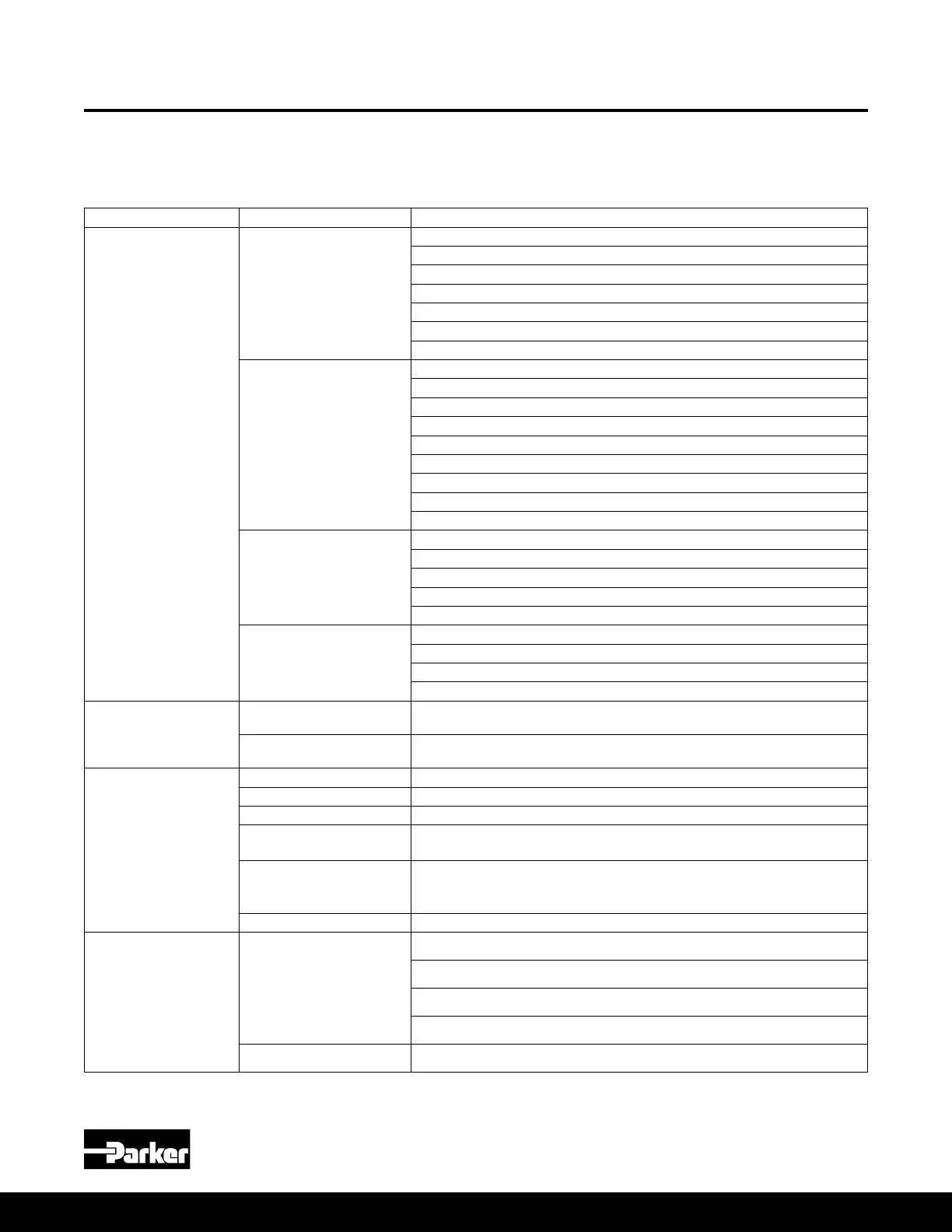

Effect of Trouble Possible Cause Fault Which Needs Remedy

Noisy pump

Air in uid

Leak in inlet line

Low uid level

Turbulent uid

Return lines above uid level

Gas leak from accumulator

Excessive pressure drop in the inlet line from a pressurized reservoir

Inlet line strainer acting as air trap

Cavitation in

rotating group

Fluid too cold

Fluid too viscous

Fluid too heavy

Shaft speed too high

Inlet line too small

Inlet strainer too small

Inlet strainer too dirty

Operating altitude too high

Inlet pressure too low

Misaligned shaft

Faulty installation

Distortion in mounting

Axial interference

Faulty coupling

Excessive overhung loads

Mechanical fault in pump

Piston and shoe looseness or failure

Bearing failure

Incorrect port plate rotation

Eroded or worn parts in the displacement control

Erosion on barrel ports

and port plate

Air in uid See noisy pump above

Cavitation See noisy pump above

Pressure shocks

Cogging load Mechanical considerations

Worn relief valve Needed repairs

Worn compensator Replace

Slow response in check

valves

Replace or relocate

Excessive

decompression

energy rates

Improve decompression control

Barrel blow-off Rotating group worn, excessive case pressure

Compensator

instability

Line capacitance (line

volume, line stretch, ac-

cumulator effects)

Change line size or lengths

Add or remove hose

Add orice in load sense line

Increase load sense differential pressure

Outlet port check valve Relocate check valve further from outlet port

Trouble Shooting

Loading...

Loading...