68

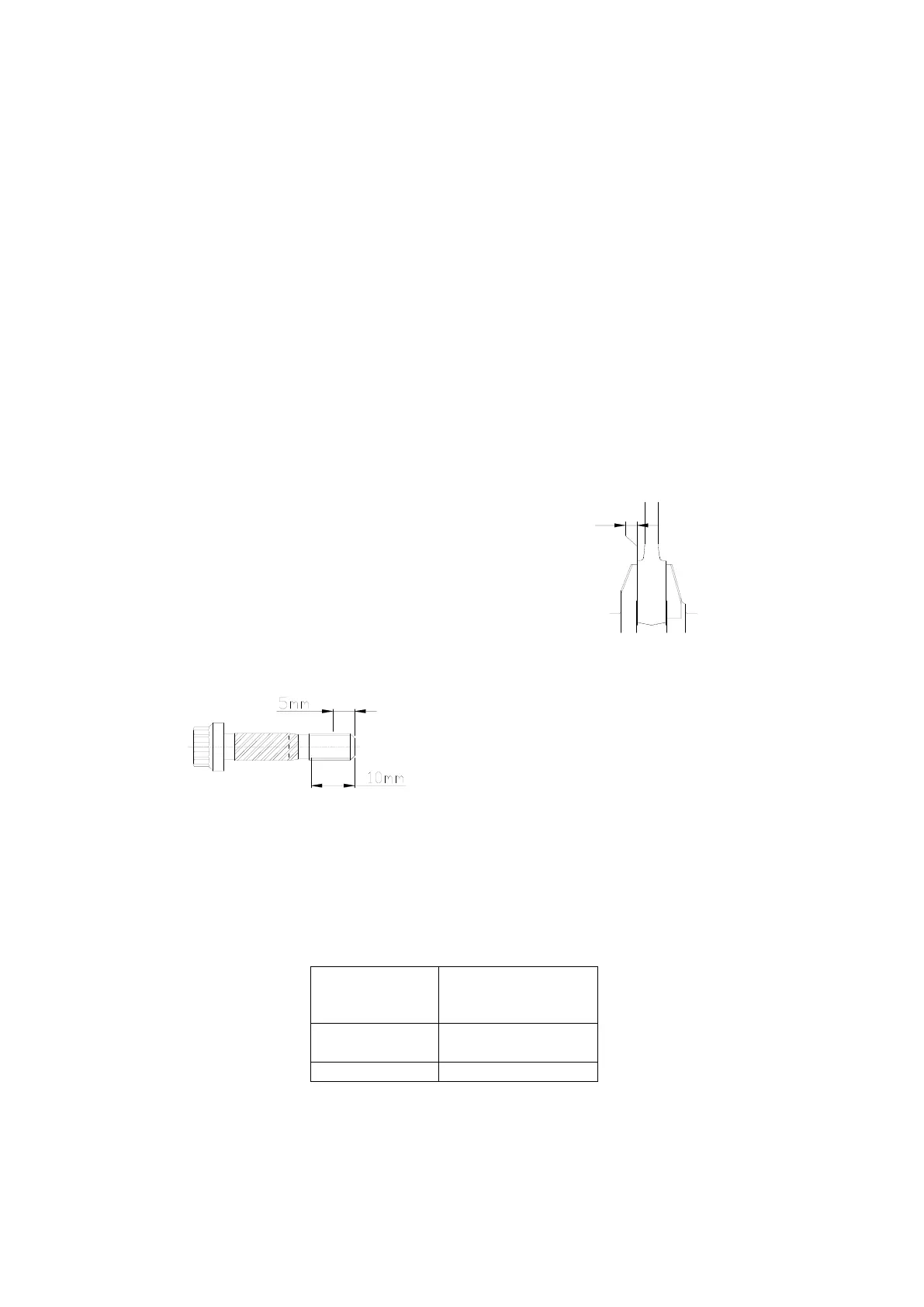

3. Measure the clearance of piston ring end face with a clearance gauge; If it does not

meet the specified value, replace it.

End face clearance (during installation): Top ring 0.15~0.30 mm

Second ring 0.30~0.50 mm

Oil ring 0.20~0.70 mm

4. Install the piston ring on the piston, and measure the clearance between the piston ring

and the piston ring groove with a clearance gauge; If it does not meet the specified

value, replace it.

Specified clearance: Top ring 0.02~0.06 mm

Second ring is 0.02~0.06 mm

Oil ring 0.04~0.18 mm

Inner diameter of connecting rod small end

Measure the inside diameter of the small end. If it does not meet the specified value,

replace it.

Inner diameter of small end: 15.985~15.998 mm

Connecting rod large end backlash

Measure the big-end backlash.

If it does not meet the specified value,

replace the connecting rod or crankshaft or both.

Large end backlash: 0.05~0.22 mm

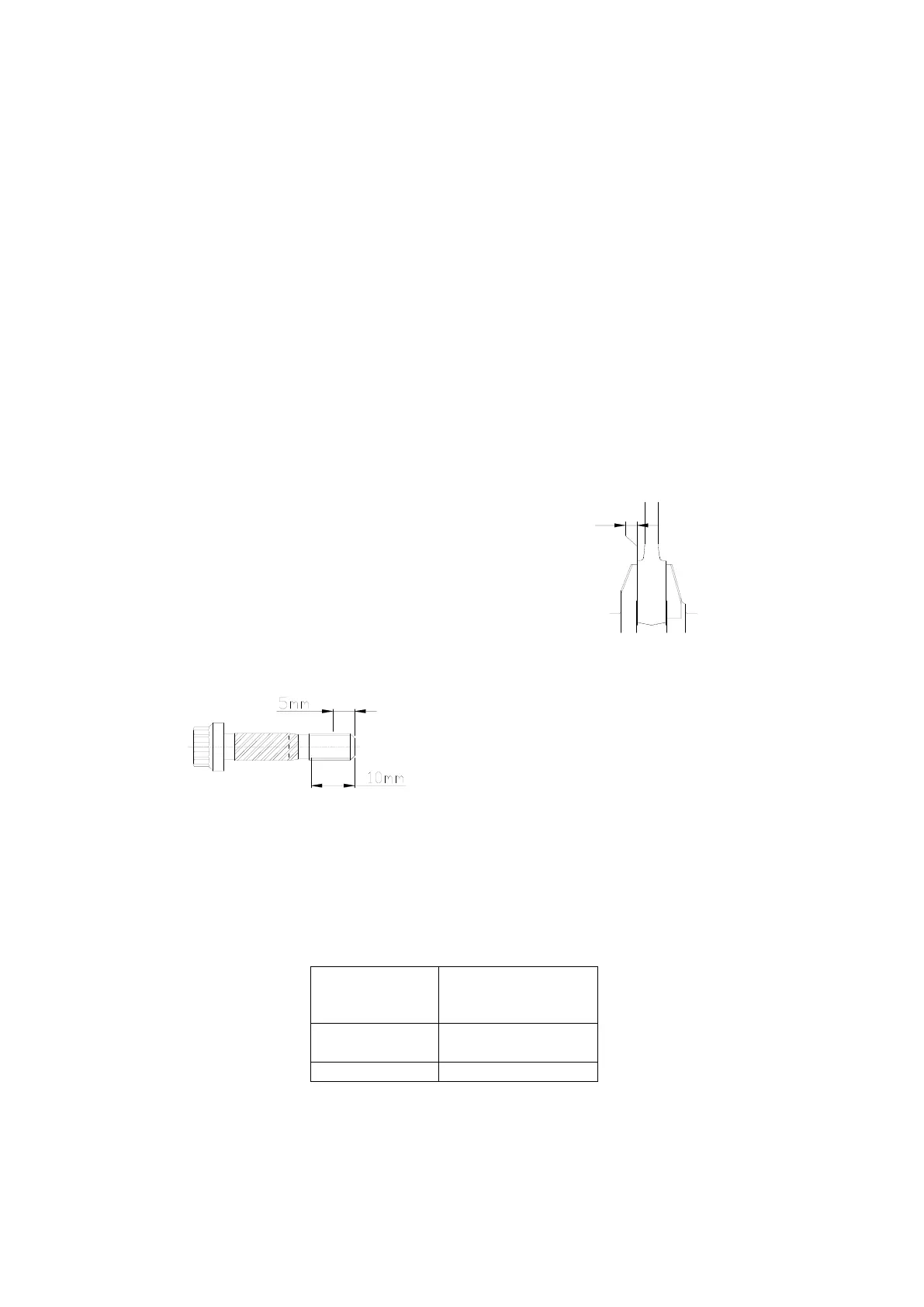

Check connecting rod bolts

1. Check the thread diameter of the connecting rod bolt at the position shown in the

figure.

2. Calculate the diameter difference of two threads; If it does not meet the specified value,

replace it.

Thread diameter difference of connecting rod bolt: 0~0.1 mm

Crankshaft

1. Measure crankshaft main journal diameter, crank pin diameter and crank pin width. If

they do not meet the specified value, replace the crankshaft.

Loading...

Loading...