69

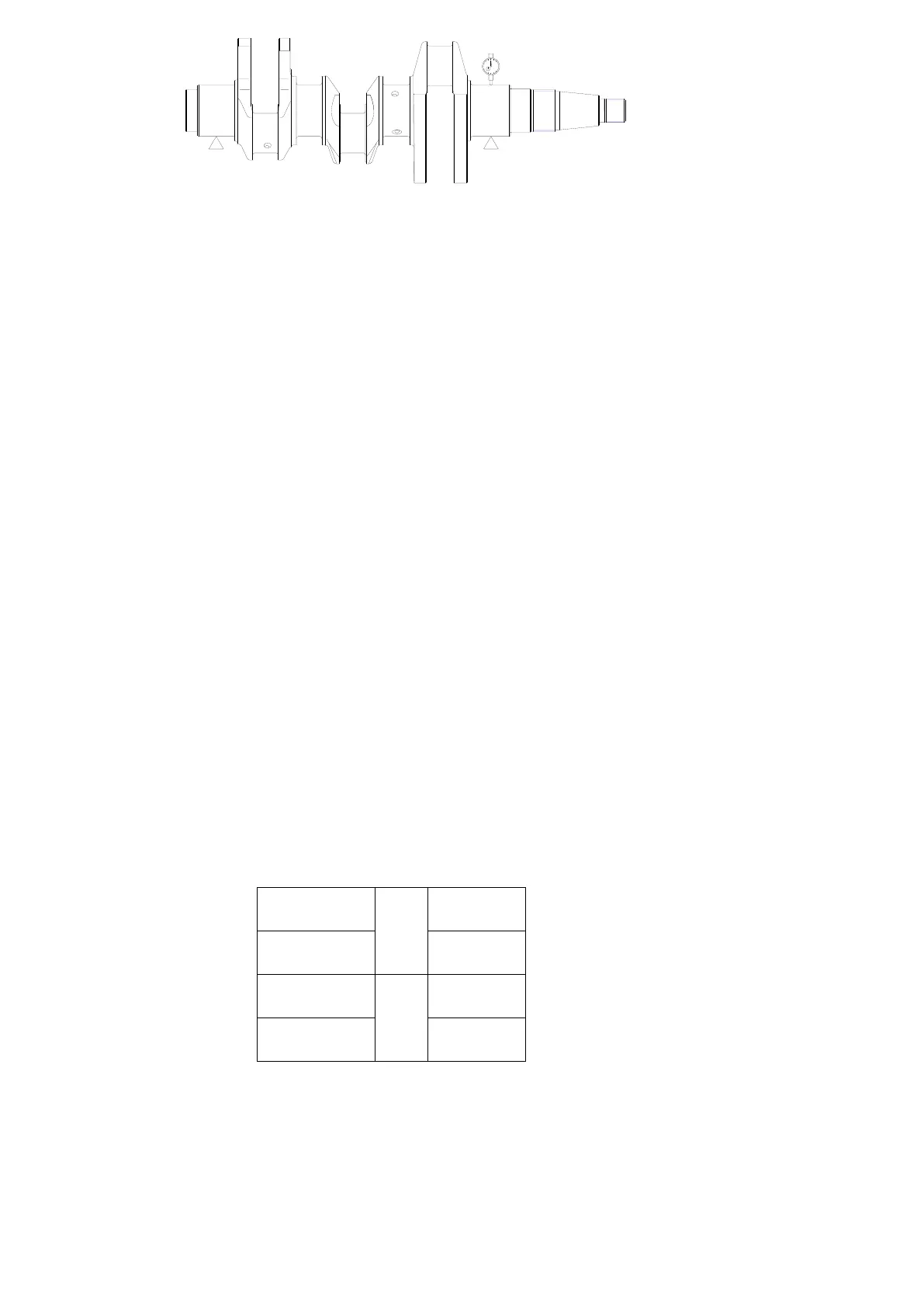

Crankshaft runout limit: 0.04mm

Crank pin oil clearance

1. Place a plastic clearance gauge on the crank pin and make it parallel to the crankshaft.

2. Fit the connecting rod and bearing bush on the crank pin.

3. Tighten the connecting rod bolts according to the specified torque.

Seating torque: First time 6 Nm

Second time 17 Nm

4. Remove the connecting rod and measure the compressed width of the plastic clearance

gauge; If it exceeds the specified value, replace the connecting rod bearing bush.

Oil clearance: 0.020~0.052mm

Note:

Do not turn the connecting rod until the measurement is completed.

Main journal oil clearance

1. Clean the bearing bush, main journal, and the mounting surface of the engine body and

engine base.

2. Install the bearing bush and crankshaft to the engine body.

3. Place a plastic clearance gauge on the main journal and parallel it to the crankshaft

Note:

Do not place the plastic clearance gauge on the oil hole of the main journal.

4. Install the bearing bush on the engine base and the engine base on the engine body.

5. Tighten bolts with specified torque in the order of numerical symbols on the engine

base.

Seating torque:

6. Remove the engine base and measure the compressed width of each plastic clearance

gauge; If it exceeds the specified value, replace the bearing bush.

Oil clearance: 0.012~0.044mm

Note:

Do not turn the crankshaft until the measurement is completed.

Body and engine base

Loading...

Loading...