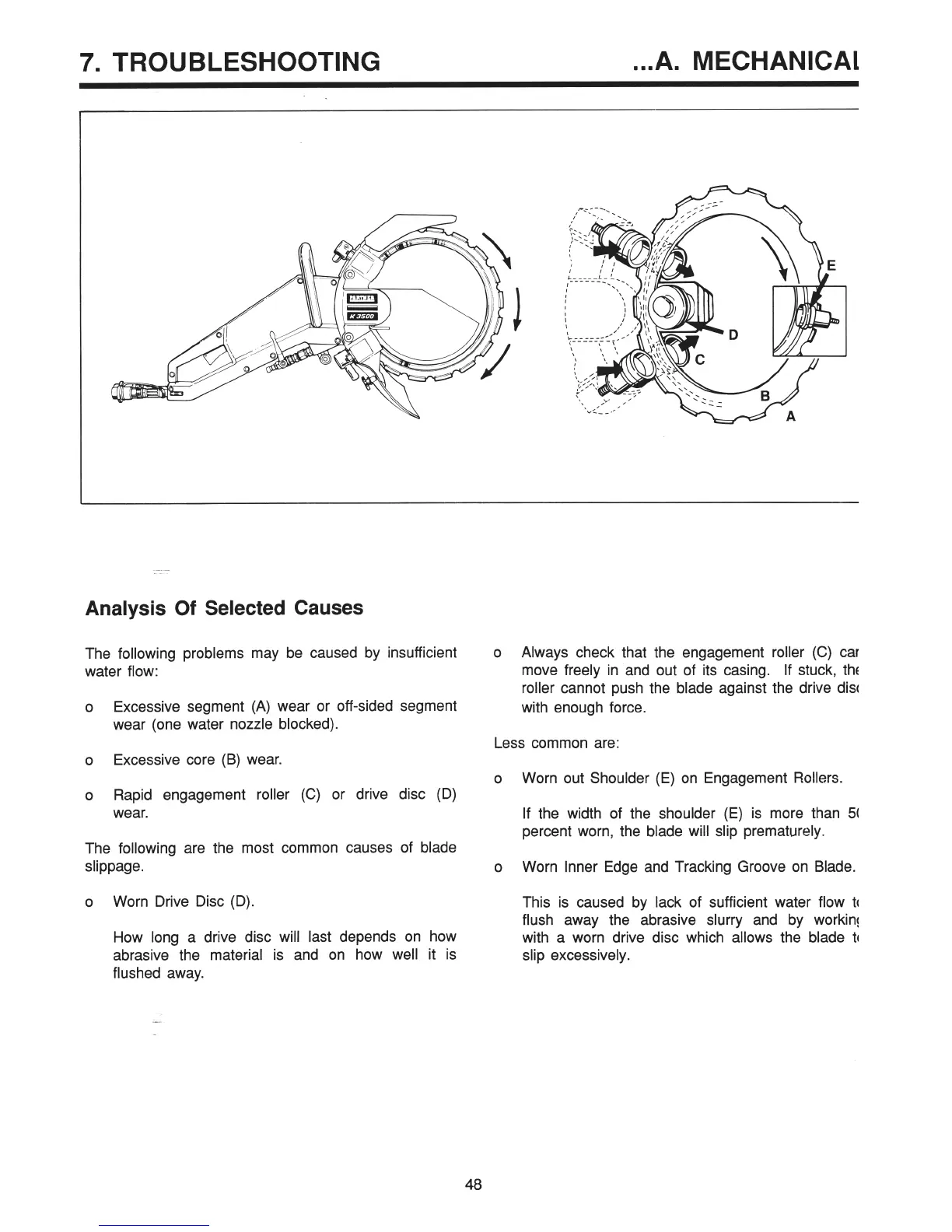

7. TROUBLESHOOTING

. ..A. MECHANICAL ”

--

Analysis Of Selected Causes

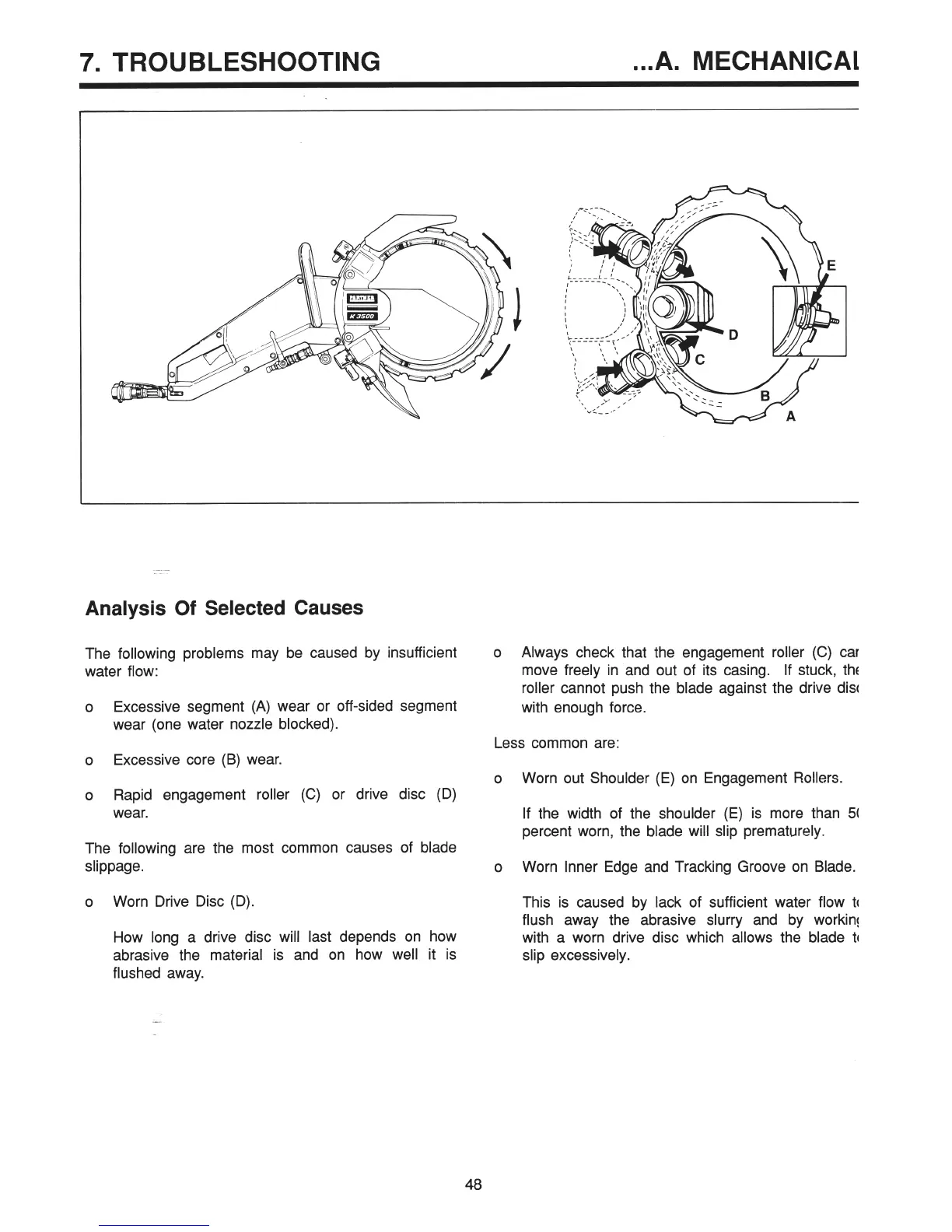

The following problems may be caused by insufficient

water flow:

o Excessive segment (A) wear or off-sided segment

wear (one water nozzle blocked).

o Always check that the engagement roller (C) can

move freely in and out of its casing. If stuck, the

roller cannot push the blade against the drive disc

with enough force.

Less common are:

o Excessive core (B) wear.

o Rapid engagement roller (C) or drive disc (D)

wear.

The following are the most common causes of blade

slippage.

o Worn Drive Disc (D).

How long a drive disc will last depends on how

abrasive the material is and on how well it is

flushed away.

o Worn out Shoulder (E) on Engagement Rollers.

If the width of the shoulder (E) is more than 50

percent worn, the blade will slip prematurely.

o Worn Inner Edge and Tracking Groove on Blade.

This is caused by lack of sufficient water flow to

flush away the abrasive slurry and by working

with a worn drive disc which allows the blade to

slip excessively.

-

48

Loading...

Loading...