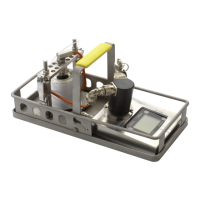

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

RPU 352, RPU 353, RPC 80, RPC 50 Page 47 of 112

In your case the instrument has wrongly sensed a battery change. You should follow the

instructions on the display and charge the battery as if it were new. The internal clock settings

and any saved files will have been lost. If the same problem occurs again within a short time

then the battery is beginning to fail and you should fit a new exchange unit.

7) The charge rate shown on the RPC-80 is not the same as that shown on the PU monitor.

Which is correct?

The RPC-80 is compatible with the RPU-352, PRU-353PU & pressure monitor but it was

designed for use with equipment that has a different battery type. The definitions of the charge

rates are not exactly equivalent but charging will take place correctly. Refer to the display on

the PU monitor for the correct charging information.

16.2 CONTROLS

8) Which switches control the display backlight?

The display backlight is switched on by any of the following actions: activating any switch (even

those that have no other function at the time), plugging or unplugging anything into either socket

or starting any communications activity that causes a message to be displayed. The backlight

will switch off again after one minute unless another action keeps it on.

If you only wish to switch on the backlight you should use the I/O (on/off) switch because then

there is no chance of the switch causing any other unwanted operation (unless you hold it for

more than 10 seconds!).

ONLY FOR PRU-353:

9) Why can’t I zero the pressure channel? The message tells me that “error is too great”.

You should set the zero for the pressure channel before each recording run to compensate for

changes in atmospheric pressure. Therefore, the pressure port must be open to the

atmosphere and so you should set the zero before you connect up to the pressure fitting on the

container. The pressure must be within ±0.5 bar of standard atmospheric pressure otherwise

the zero correction cannot be made.

If the port is open to the atmosphere and you still get the message “Can’t set zero - the error is

too great” then the pressure port may be blocked. This is most likely to be a problem when

pasteurising soft drinks with high sugar content. Clean the port as directed in the “Maintenance”

section of the operating manual. If the problem persists then there may be a fault in the

pressure sensor.

Loading...

Loading...