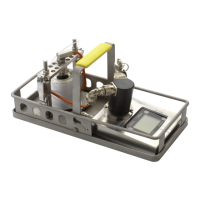

HAFFMANS RPU 352, RPU 353, RPC 80 RPC 50

2

RPU 352, RPU 353, RPC 80, RPC 50 Page 97 of 112

APPENDIX I BACKGROUND INFORMATION

PU calculation

The Pasteurisation Unit (PU) is defined as relating to the sterilising effect

observed when the product is held for one minute at a temperature termed the

Base value. At this temperature therefore, 1 PU per minute is achieved.

Experiments on various mixtures of the common brewery biological contaminants

showed that at temperatures over about 50°C there i s an approximately ten-fold

increase in sterilising effect for every 7°C increa se in temperature. For example,

if the time required to kill a population of micro-organisms at 60°C is found to be 5

minutes then if the temperature were to be increased to 67°C the time required

would be only 0.5 minutes. The increase in temperature required to produce a

ten-fold increase in kill rate is termed the Z value. The Z value in this case is

therefore 7°C.

For beer the PU is normally defined by a Base value of 60°C and a Z value of

7°C. The same definition is often used for soft dr inks and other beverages.

Where there is any possibility of spore-forming bacterial contamination being

present (for example in tomato juice) very much higher temperatures are required

for pasteurisation. In these situations the definition of Base value 80°C and Z

value 10°C is often used. Other definitions are a lso in use outside the brewing

industry.

At product temperatures below about 50°C it is doub tful that any significant

sterilising effect is achieved even though from a strictly mathematical point of

view the correct PU total could still be obtained, given enough time in the

pasteuriser. For this reason is it desirable to set a temperature level below which

no PU’s are added to the total calculated by a PU monitor. This is termed the PU

cut-off temperature.

Set the PU cut-off temperature at least 5°C lower t han the planned product

temperature in the holding zone of the pasteuriser. Higher values will give a very

conservative figure for PU achieved and will reduce the repeatability of the result

because the product temperature will be changing only slowly as it crosses the

cut-off temperature threshold. For beer the cut-off is not normally set below

50°C.

The next three screens allow you to adjust the PU calculation which will apply to

both temperature channels.

Loading...

Loading...