17

TAURUS™ VS Variable Speed Pump Installation and User’s Guide

Troubleshooting (Cont.)

Problem Possible Cause

Corrective Action

Pump runs without flow.

Impeller is loose

Air leak

Clogged or restricted plumbing

Check that pump is spinning by looking at fan on back

of pump. If so, check that pump impeller is correctly

installed.

Check plumbing connections and verify they are tight.

Check for blockage in suction side piping.

Checked for blockage in discharge piping including

partially closed valve or dirty filter.

Errors and Alarms

If an alarm is triggered the drive’s LCD screen will display the fault code text and the Taurus™ VS Variable Speed

Pump will stop running. Disconnect power to the pump and wait until the keypad LEDs have all turned off. At this

point, reconnect power to the pump. If the error has not cleared then proper troubleshooting will be required. Use

the error description table below to begin troubleshooting.

21 – Communication Link between the HMI and Motor control has been lost: Check the jacketed wire on

the back side of the keypad inside the drive top cover. Ensure that the 5 pin connector is properly plugged into the

socket and that there is no damage to the cable.

1A – Power Module over current detected: If this error displays multiple times, then there may be a problem

with the pump’s rotating assembly. Please disassemble the pump and investigate to see if there is a problem with

the impeller or mechanical seal. See page 14 “Pump Disassembly” for instructions for disassembling the pump.

0F – Absolute AC Under Voltage Detected: This indicates that the supply voltage has dropped below the

operating range of 99v. This could be caused by normal voltage variation and will clear itself. Otherwise there

could be excess voltage sag caused by improper installation or improper supply voltage.

17,16, 02, 08, 04, 06, 09, 0A – Internal Errors: These errors can occur based on operating conditions

and the UL 60730 required self-diagnostic safety software. If they do not clear after multiple restart attempts the

drive should undergo a hard power cycle. Disconnect main power by turning off the breaker long enough for the

keypad LEDs to turn off. After power is reconnected if one of these errors continues to reappear, the drive may

need service.

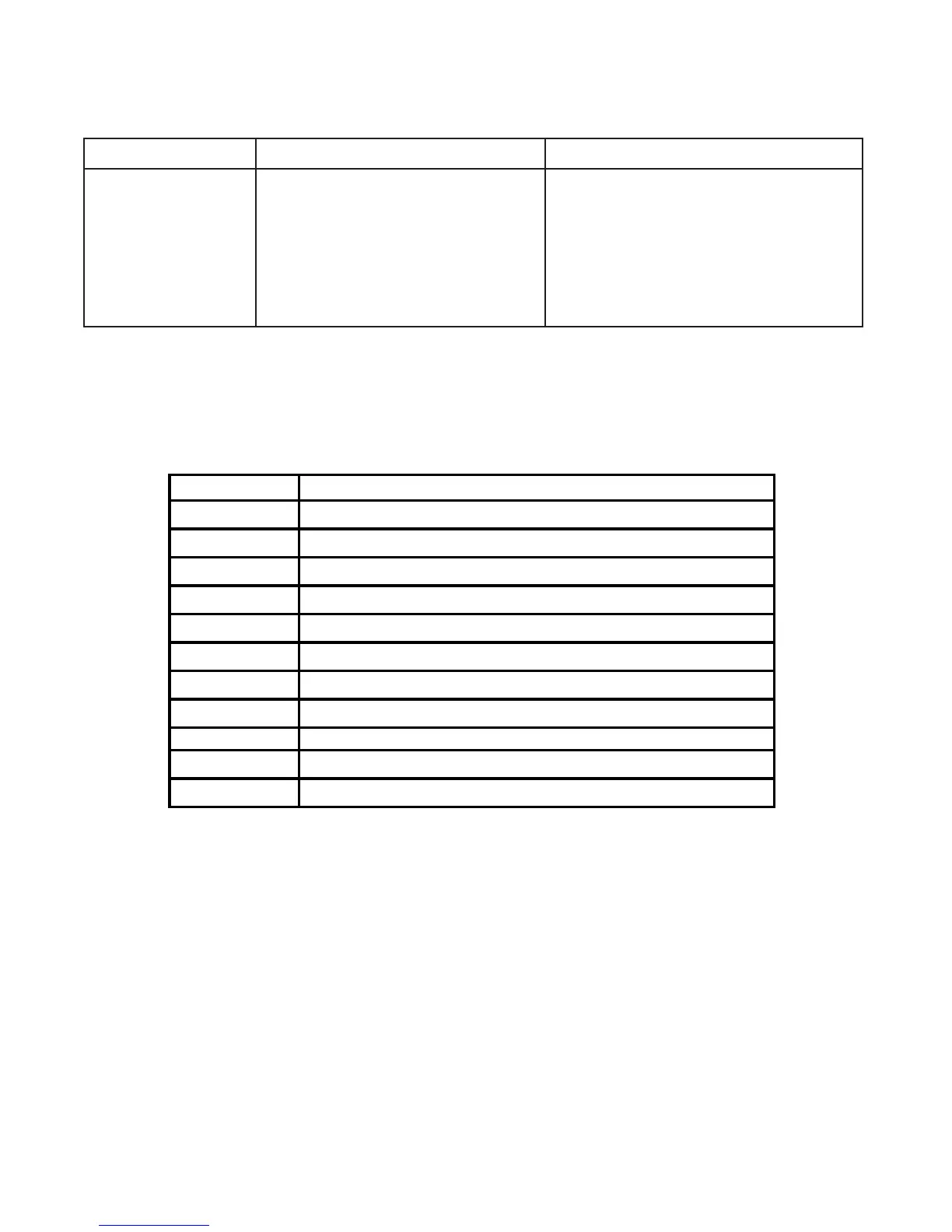

Communication link between HMI and motor control has been lost

Power Module over current detected

Phase Current Offset out of range

Phase Current Imbalance detected

Absolute AC under voltage detected

Absolute Phase current limit exceeded

Absolute Diode Bridge temperature limit exceeded

Absolute Power Module temperature limit exceeded

Absolute Power Factor Correction (PFC) temperature limit exceeded

DC bus over voltage detected

DC bus under voltage detected

Loading...

Loading...