5

TAURUS™ VS Variable Speed Pump Installation and User’s Guide

Control with External Control and Digital Inputs

The user can run the Taurus™ VS Variable Speed Pump with automation external controls, allowing all four

programmed Speeds to be controlled remotely. The pump has a sealed connector that can be used with Pentair

External Control Wiring Kit (Pentair P/N 353129Z) to run the Speeds using digital input signals. When there is an

external low voltage signal present on the Speed Digital Input line, the pump will run the speed programmed for

that Digital Input. The supplied +5V signal is the recommended input used for external control and Speed Digital

Inputs.

Connecting to External Controls

Using the Supplied Low Voltage Signal for Digital Control

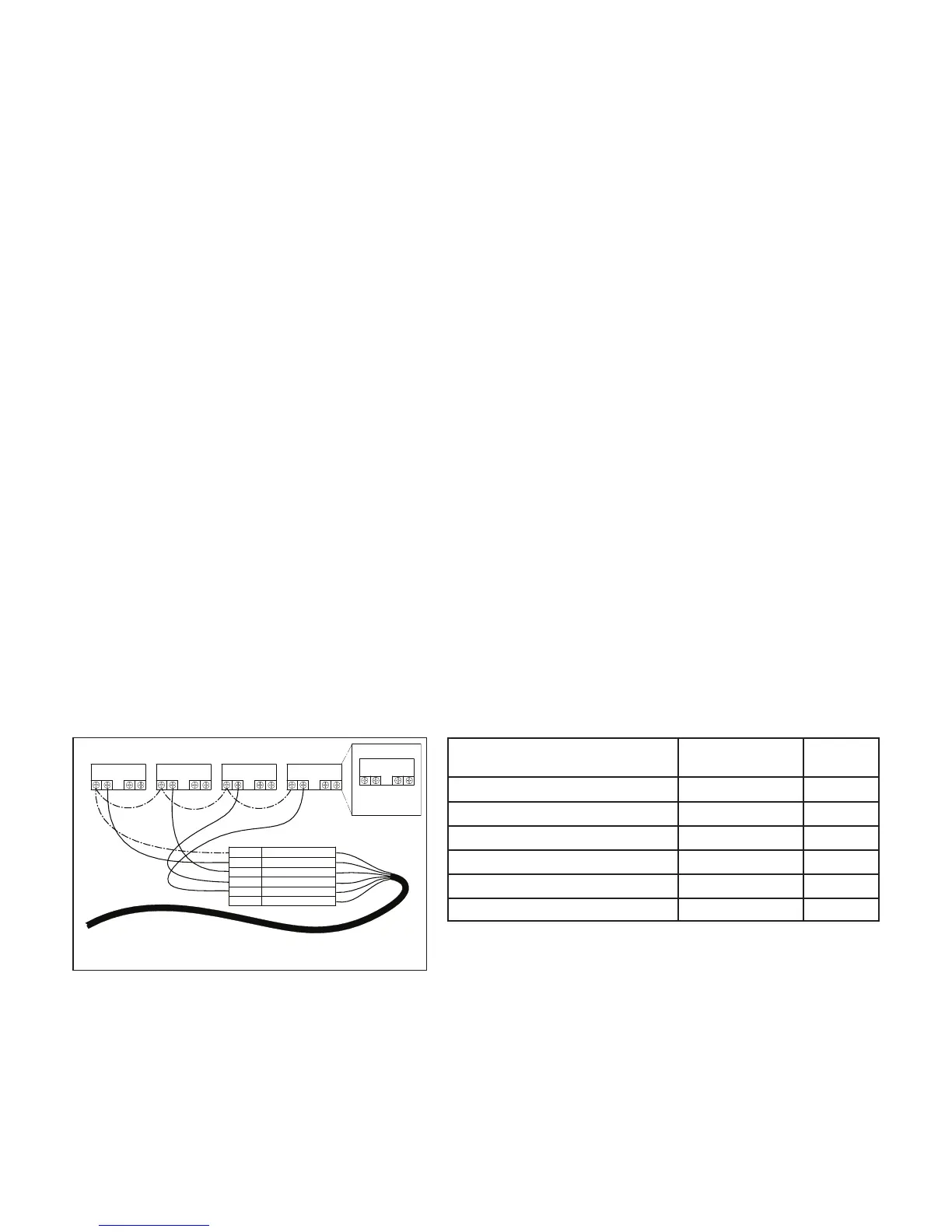

This pump provides a low voltage output signal that can be used to trigger its own Digital Inputs. This signal will

need to be switched via the External Control system to engage the speed that it is connected to as in Figure

4. This could be an automation relay or switch in another piece of equipment. This feature could be useful for

ensuring that the pump is running a certain program when a specific speed is needed to perform a task.

The wire included with the External Control Wiring Kit (Pentair P/N 353129Z) will need to be cut to length for the

installation. Do not leave excess wire around the installation, and the wire should be supported by something

rigid if conduit is not used. At one end of the cable is a custom molded, watertight connection that plugs into the

panel connection on the side of the drive. The opposite end has 6 wires that are defined by Table 1 below. When

using the +5V signal supplied by the drive, the speeds should be wired as shown in Figure 4.

When there is a low voltage signal present on the Speed Digital Input line the pump will run the speed that is

programmed for the speed that is being triggered. The +5V signal supplied via the (red) wire is the suggested

input for the Speed Digital Inputs. See Figure 4.

Note: Any relay can be associated to any Digital Input. Figure 4 shows one of many potential wiring options

available to the installer, allowing you to install External Controls in the way that best suits your needs.

Note: This +5V Signal (red wire) is output from the drive only, and should never be wired to another power

supply!

When a Speed Digital Input is triggered, the LED above the Speed button will begin to blink and the display will

toggle between the display parameter and “EC” indicating an External Control is running. The pump will run this

speed as long as the Digital Input trigger is present. This will override the schedule or any user inputs for Speed

selections via the keypad. The Display button is still functional along with the Start/Stop button. Once the Digital

Input trigger is removed from all of the Speed Digital Input wires, the pump will resume the programmed schedule.

RELAY 1 RELAY 2RELAY 3RELAY 4

RELAY

LINE 1

LOAD 1

LOAD 2

LINE 2

POWER RELAY (DPST)

RED

+5V OUTPUT FOR D.I. TRIGGER

GREEN SPEED 1 DIGITAL INPUT

YELLOWSPEED 2 DIGITAL INPUT

ORANGE SPEED 3 DIGITAL INPUT

BROWN

SPEED 4 DIGITAL INPUT

BLACK

GROUND

Figure 4:

External Control Kit Wiring Diagram

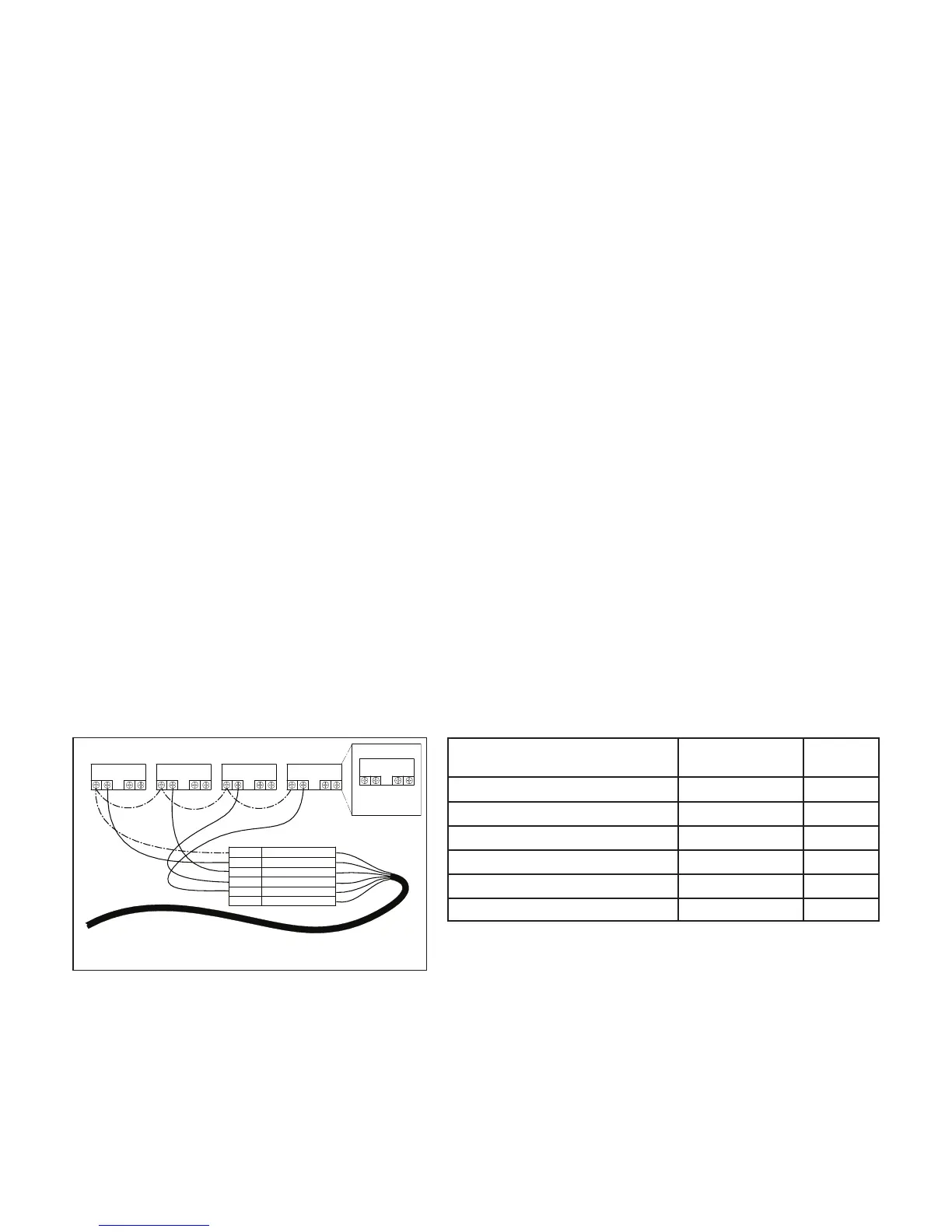

Denition Signal Range

Wire

Color

+5V Output for Digital Inputs 0 - 20mA Red

Speed 1 Digital Input 0, 5 - 30V AC/DC Green

Speed 2 Digital Input 0, 5 - 30V AC/DC Yellow

Speed 3 Digital Input 0, 5 - 30V AC/DC Orange

Quick Clean Digital Input 0, 5 - 30V AC/DC Brown

Common Ground 0V Black

Table 1:

Automation Control System Input Wiring Chart

Loading...

Loading...