1204F - DEF System Supplement

5.5.2 DEF Component Relative Positioning

See mandatory requirements section 2.8

5.6 DEF Tank Service Considerations

5.6.1 DEF Tank Filling

The ISO 22241-4 standard is primarily aimed at defining the standard for the refilling interface. It is

recommended that all refilling be performed utilizing an ISO 22241-4 compliant nozzle.

The fill neck interface is poke-yoke from a diesel fill nozzle by it is smaller in diameter. The DEF

nozzle has an OD of 19mm ± 0.25mm. The fill neck ID is 19.75mm ± 0.25mm.

The fill neck is designed to:

• Comply with ISO 22241-4

This standard is primarily aimed at defining the standard for the refilling interface. It is

recommended that all refilling be performed utilizing an ISO 22241-4 compliant nozzle.

• Fill at a rate, which is faster than the fuel tank.

It is recommended that the target design flow rate for DEF splash fill systems is between 20 to

40 LPM with 0 splash back.5.5

• Help discourage or prevent mis-fill

• Prevent overfill

All adapters supplied by Perkins include a magnetic toggle. The customer’s fill nozzle may or may

not have the magnetic safety switch.

The nozzle switch only prevents DEF from being dispensed into a non-DEF tank. The neck size

prevents a standard diesel or gasoline fill nozzle from being inserted into the tank and a resulting

miss fill. There are, however, no devices in the adapter preventing a determined party from

inserting a non-standard fill hose and filling the tank with fluids other than DEF.

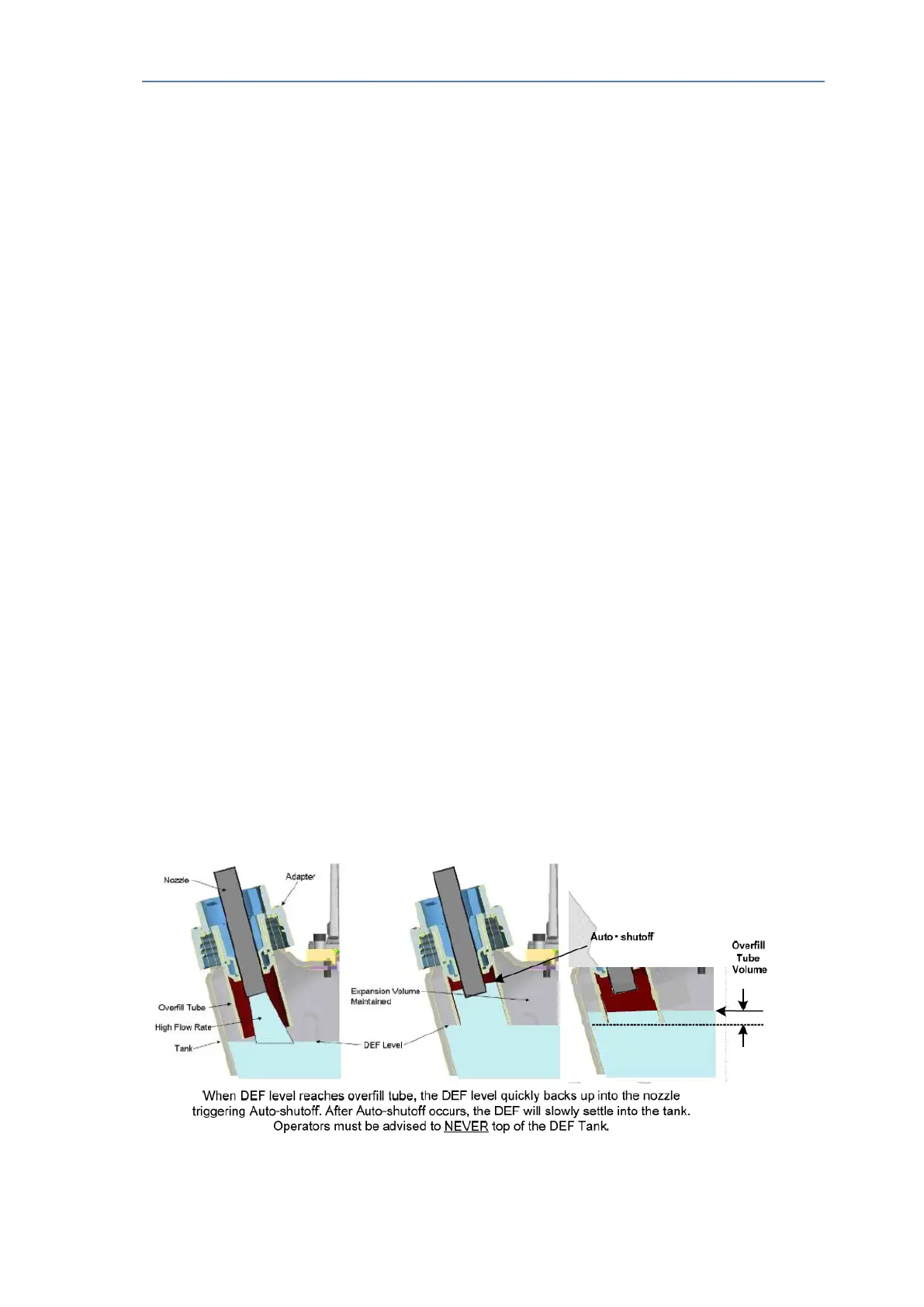

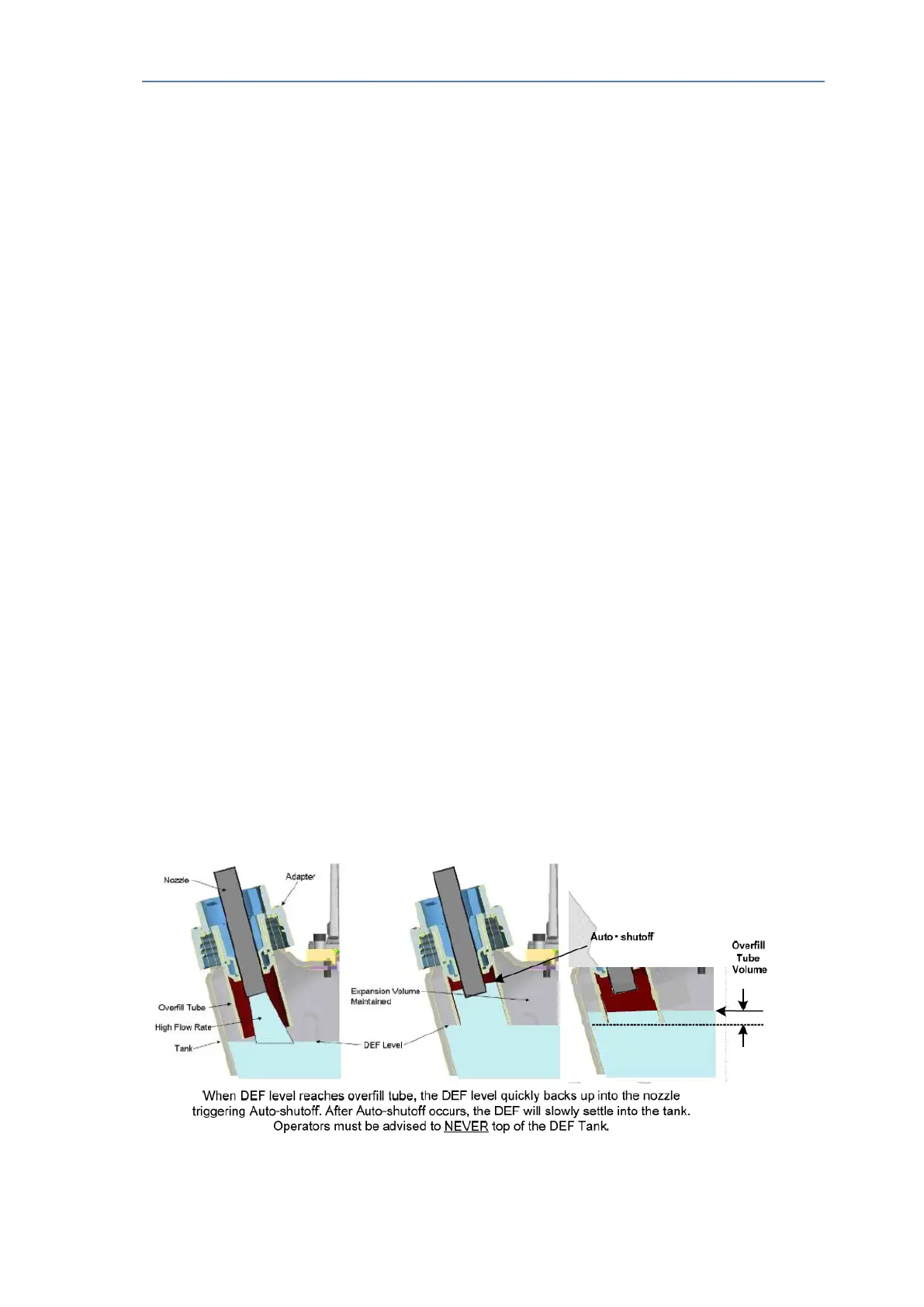

5.6.2 Overfill Protection

The DEF tank requires an expansion volume be maintained for when DEF freezes. An expansion

volume of approximately 10% must be maintained. Overfilling of the tank will result in tank rupture

upon freezing.

Overfill protection can be provided by simply extending a tube to the required level, and allowing

the flow to back-up into the nozzle activating its auto shut-off. After the nozzle is shut off, a weep

hole in the adapter will allow the DEF to slowly settle out of the adapter down into the tank. If the

operator then tops off the tank it will be subject to freeze expansion risk. Any operator instruction

manuals should clearly state that the operator should NEVER top of the DEF tank. See Figure 5.9

below.

Fig 5.9- DEF Tank Overfill Protection

A&I manual Publication TPD 1832 – Production issue 3. Page 39 of 41

Loading...

Loading...