1204F - DEF System Supplement

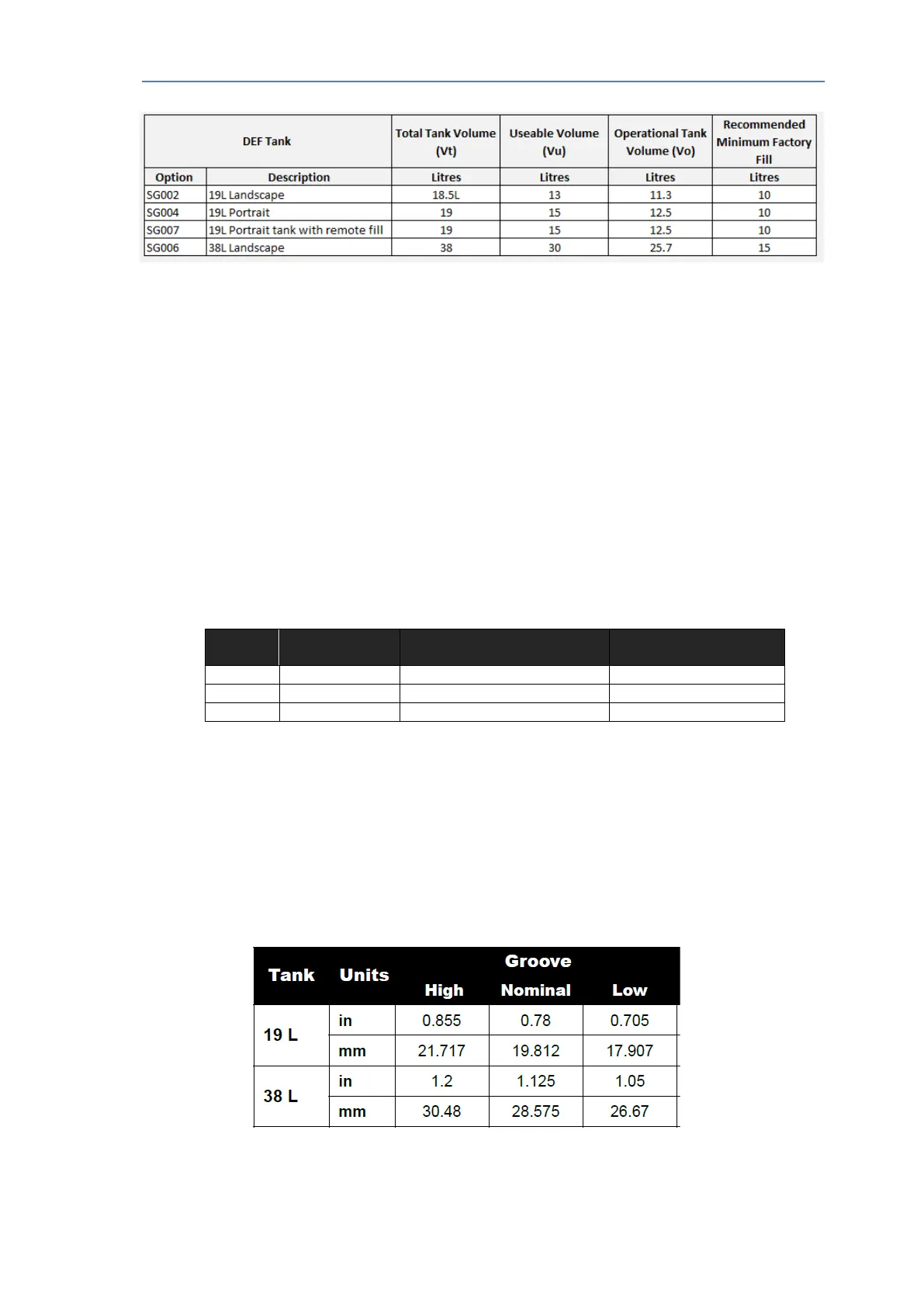

Table 5.4 - DEF tank Volumes

5.4.2 DEF Tank Mounting and Installation

• The DEF tank should be located to avoid heat sources or stagnant hot air build up which

will lead to overheating of the DEF.

• Proper distance and elevation from DEF injector –ref 5.4

• Ease of tank drain

• Ease of filling with care taken regarding spillage

• Tank fill vent away from HVAC air intake (unpleasant odor in cab may result)

• Out of direct sunlight preferred

• The tank must be +/-5° from horizontal when filling with DEF

• An anti-friction mat is recommended under the tank base.

• Table 5.5 below details the weight of the Standard DEF tank options when filled with DEF

to 100% full.

Weight (g) – 100%

DEF fill level

Table 5.5 – DEF Tank Mounting Details

5.4.3 DEF Tank Straps

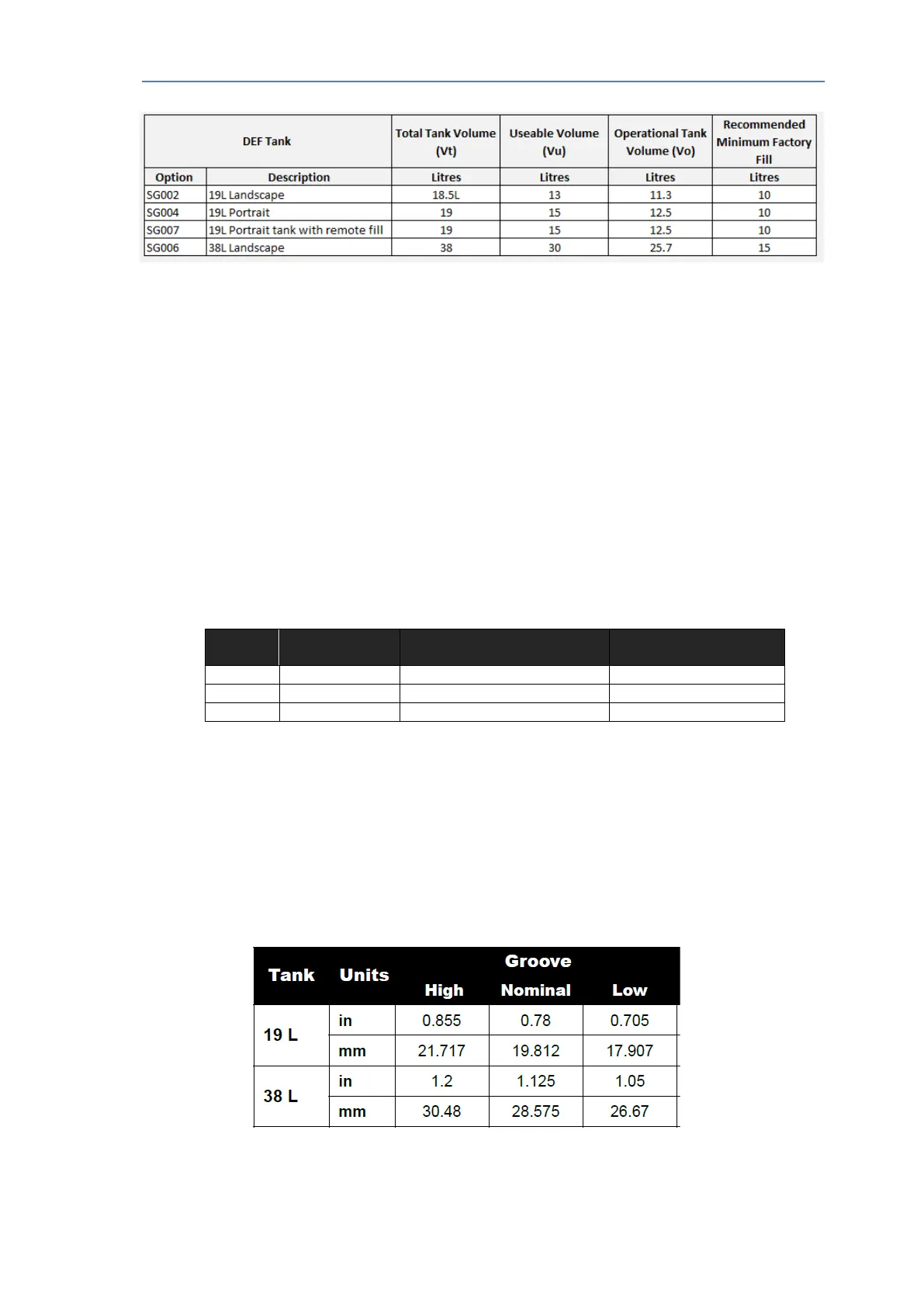

• The Perkins supplied DEF tanks feature grooves to help locate the tank straps. The groove

tolerances are shown in table 5.6 below. The Mandatory requirements are detailed in section

2 and must be adhered to.

• The strap design must consider both the static assembled conditions plus the loads from

machine operation that are typically used as design points for a given machine. It is

recommended that FEA is conducted on the tank and mounting design.

Table 5.6 – DEF Tank Groove Tolerances.

A&I manual Publication TPD 1832 – Production issue 3. Page 35 of 41

Loading...

Loading...