52 SEBU8337

Maintenance Section

Refill Capacities

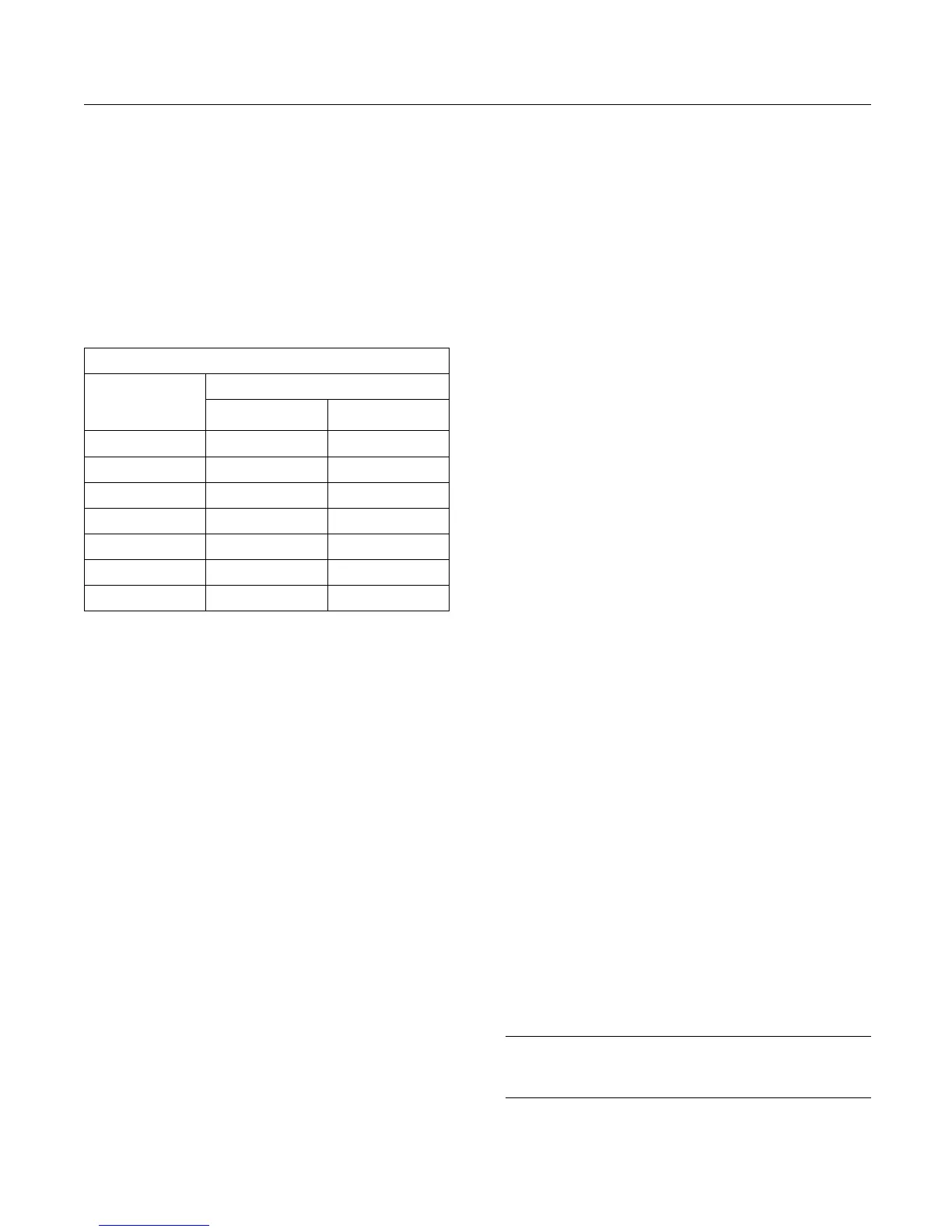

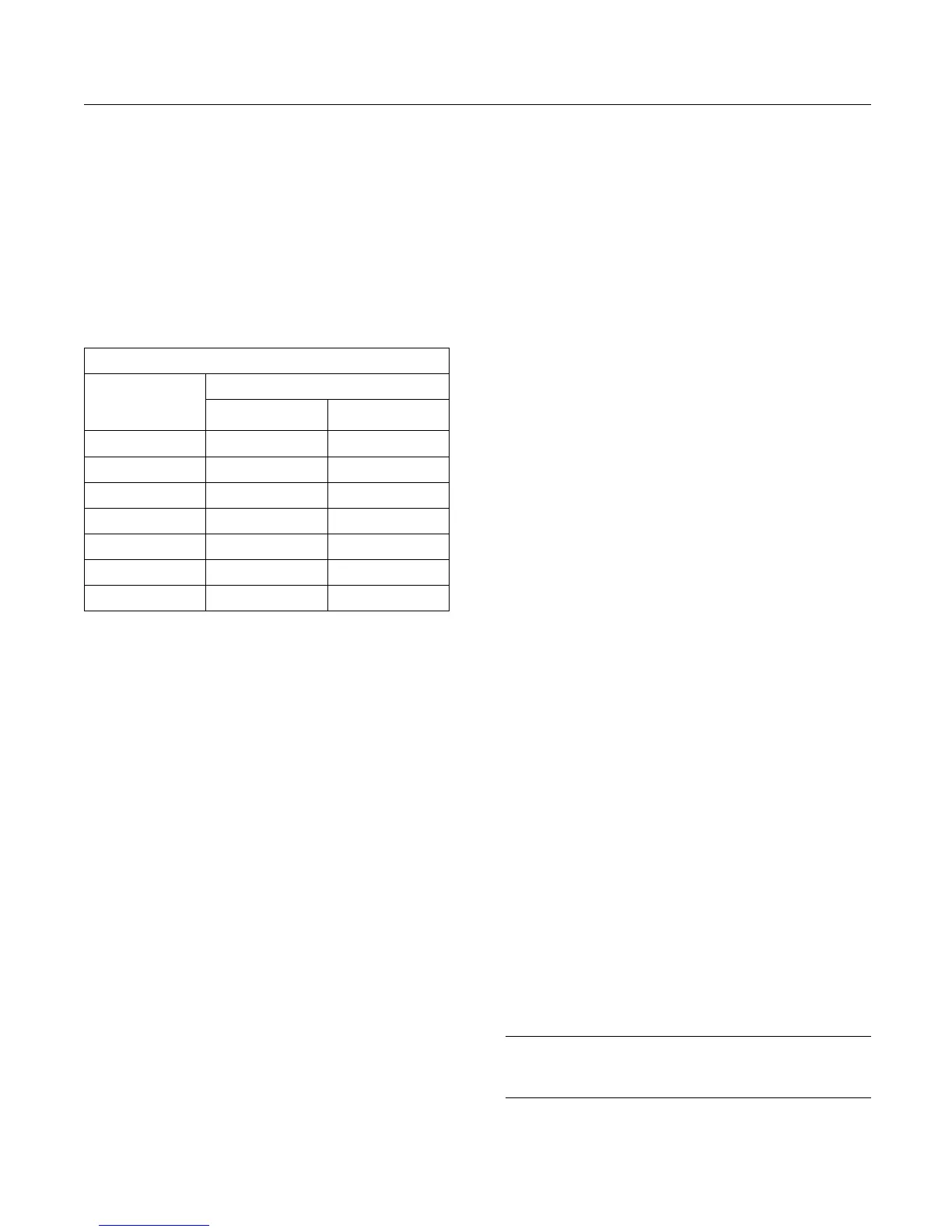

Refer to Table 1

9 (minimum temperature) in order

to determine the required oil viscosity for starting a

cold engine.

Refer to Table 19 (maximum temperature) in order

to select the oil viscosity for engine operation at the

highest ambi

ent temperature that is anticipated.

Generally, use the highest oil viscosity that is

available to

meet the requirement for the temperature

at start-up.

Table 19

Engine Oil Viscosity

Ambient Temperature

EMA LRG-1

API CH-4

Viscosity Grade

Minimum Maximum

SAE 0W20 −40 °C (−40 °F) 10 °C (50 °F)

SAE 0W30 −40 °C (−40 °F) 30 °C (86 °F)

SAE 0W40 −40 °C (−40 °F) 40 °C (104 °F)

SAE 5W30 −30 °C (−22 °F) 30 °C (86 °F)

SAE 5W40 −30 °C (−22 °F) 40 °C (104 °F)

SAE 10W30 −20 °C (−4 °F) 40 °C (104 °F)

SAE 15W40 −10 °C (14 °F) 50 °C (122 °F)

Synthetic Base Stock Oils

Synthetic base oils are acceptable for use in

these engines if these oils meet the performance

requirements that are specified for the engine.

Synthetic base oils generally perform better than

conventional oils in the following two areas:

•

Synthetic base oils have improved flow at low

temperatures especially in arctic conditions.

•

Synthetic base oils have improved oxidation

stability especially at high operating temperatures.

Some synthetic base oils have performance

characteristics that enhance the service life of the

oil. Perkins does not recommend the automatic

extending of the oil change intervals for any type of

oil.

Re-refined Base

Stock Oils

Re-refined base stock oils are acceptable for

use in Perkins

engines if these oils meet the

performance requirements that are specified by

Perkins. Re-refinedbasestockoilscanbeused

exclusively

in finished oil or in a combination with

new base stock oils. The US military specifications

and the specifications of other heavy equipment

manufacture

rs also allow the use of re-refined base

stock oils that meet the same criteria.

The process t

hatisusedtomakere-refined base

stock oil should adequately remove all wear metals

that are in the used oil and all the additives that

areintheus

ed oil. The process that is used to

make re-refined base stock oil generally involves the

process of vacuum distillation and hydrotreating the

used oil. Fi

ltering is adequate for the production of

high quality, re-refined base stock oil.

Lubricant

s for Cold Weather

When an engine is started and an engine is operated

in ambient

temperatures below −20 °C (−4°F),use

multigrade oils that are capable of flowinginlow

temperatures.

These oils have lubricant viscosity grades of SAE

0W or SAE 5W.

When an engine is started and operated in ambient

temperatures below −30 °C (−22 °F), use a synthetic

base stoc

k multigrade oil with an 0W viscosity grade

orwitha5Wviscositygrade.Useanoilwithapour

point that is lower than −50 °C (−58 °F).

The number of acceptable lubricants is limited in

cold weather conditions. Perkins recommends the

followi

ng lubricants for use in cold weather conditions:

First Choice – Use oil with an EMA DHD-1

Recomme

nded Guideline. Use a CH-4 oil that has

an API license. The oil should be either SAE 0W20,

SAE 0W30, SAE 0W40, SAE 5W30, or SAE 5W40

lubrica

nt viscosity grade.

Second Choice – Use an oil that has a CH-4

additi

ve package. Although the oil has not been

tested for the requirements of the API license, the oil

must be either SAE 0W20, SAE 0W30, SAE 0W40,

SAE 5W3

0, or SAE 5W40.

NOTICE

Shortened engine service life could result if second

choice oils are used.

Loading...

Loading...