permaPROC-8-

4. Assembly and Mounting of the Lubrication System

4.1 Mounting the Drive Unit onto a Fixing Device for Wall-Mounting

♦ Attachthesuppliedmountingdevicetothedriveunitusingthetwoenclosedhexheadbolts(M6x16)and

thetwowashers.

♦ Screwthemountingdevicewiththedriveunitontoasupportofyoursystem.Theboringtemplateofthethree

mountingscrews(141.5x45)canbeseenbelowingure3oronthetemplatethatisincluded.Youhaveto

useatleastthreehexagonscrewsM6x25(e.g.onmetalground).

♦ Beforeyouconnecttheoutletofthedriveunittothelubricanttube,youhavetomakesurethatthelubrication

pointsandthecompletelubricanttubeispre-lubricatedwiththesamelubricantthatiscontainedinthePRO

LCunit.Forthat,perma-tecoffersa400glubricationcartridgeformanually-operatedgreasepresseswiththe

requestedlubricant.

♦ Connectthelubricanttube(connectionG3/8)totheoutletofthedriveunitandinstallthetubecorrectly

betweentheoutletandthelubricationpoint.Thelubricanttubemustnotbelongerthanvemeters.

Make sure that you assemble the connections and lubricant tubes correctly and tightly to avoid possible

leakage.

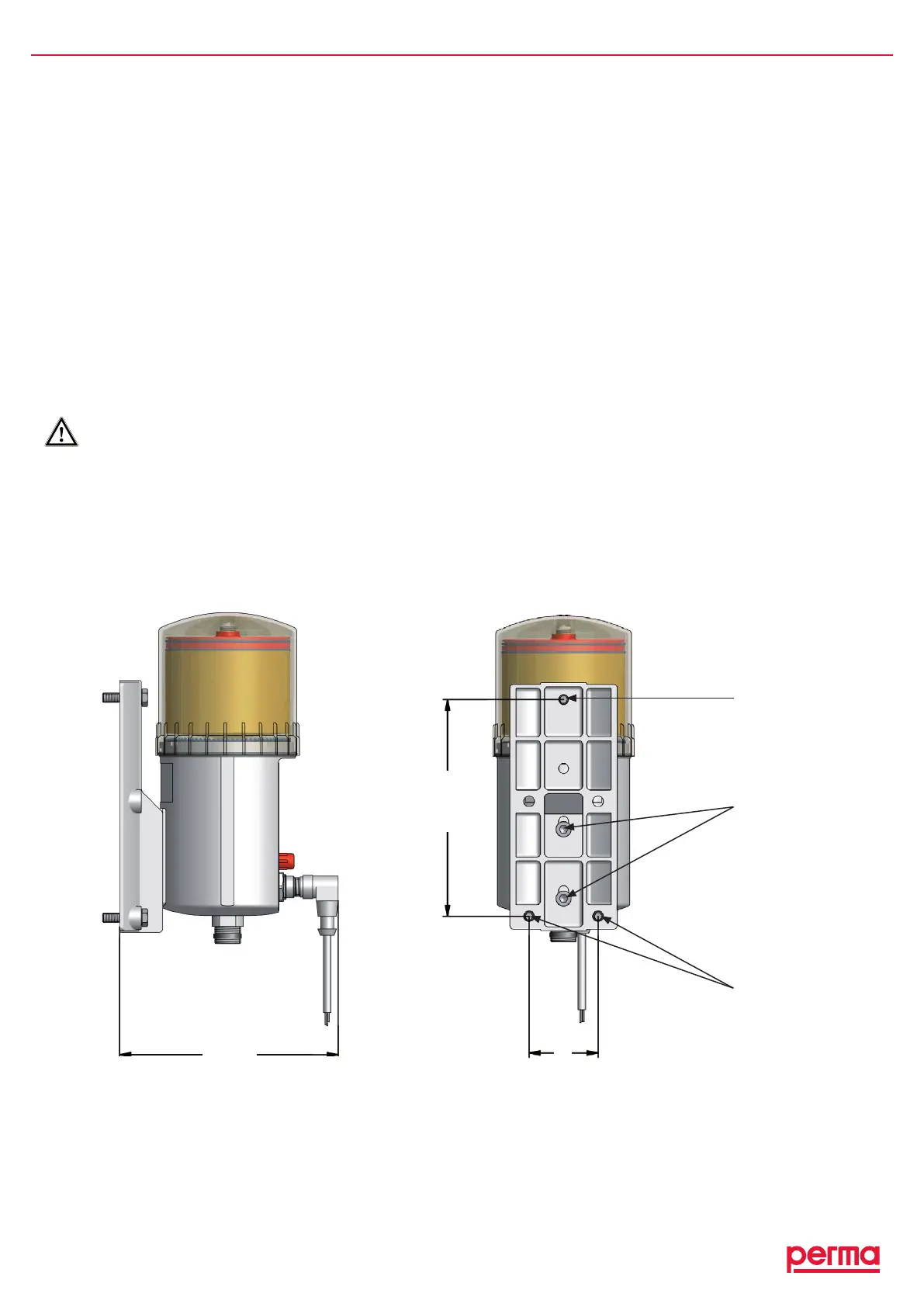

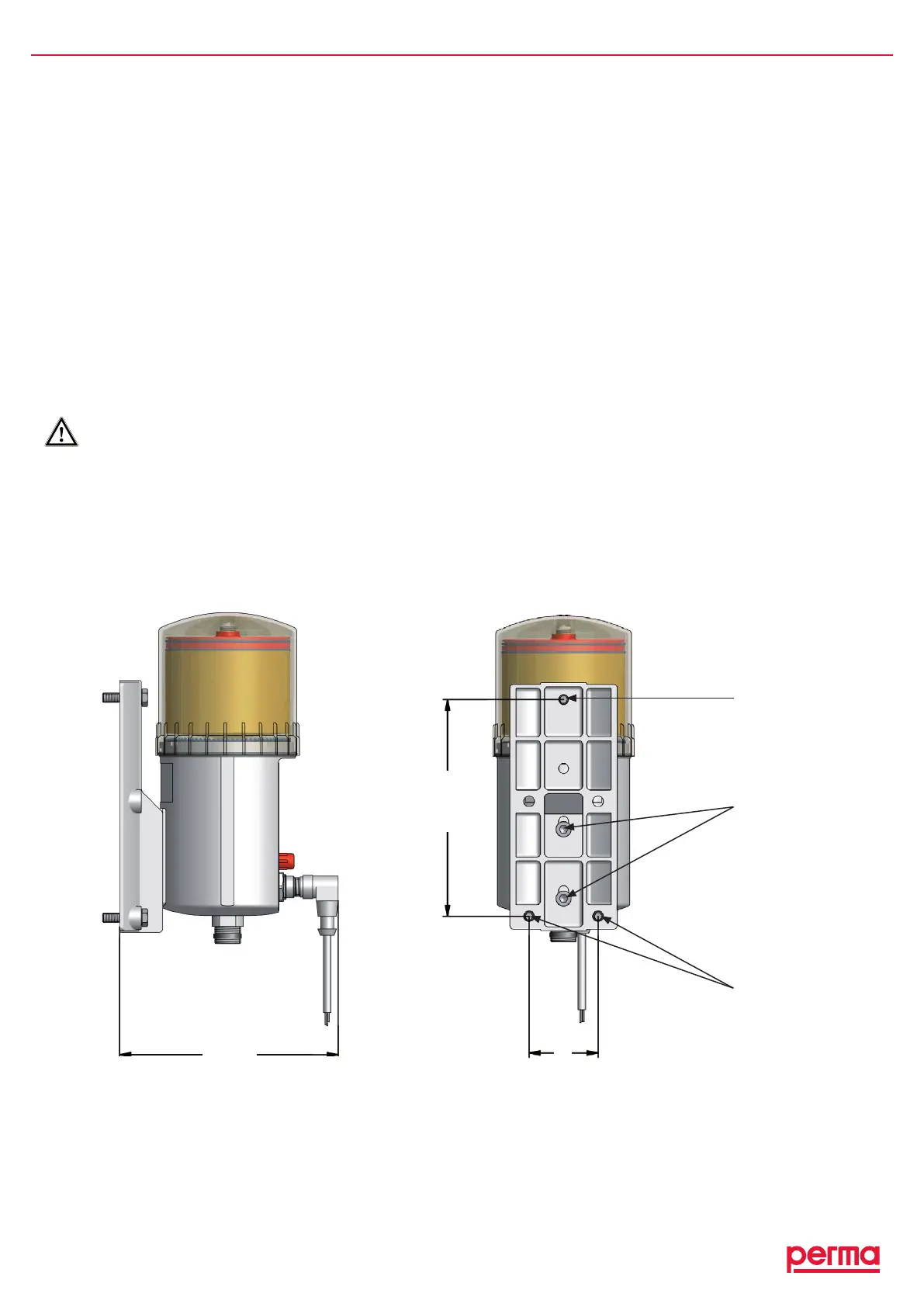

gure3

2hexheadbolts

M6x16,maximum

torque3Nm

(supplied

forattachingthe

permaPROCtothe

mountingdevice)

Hexagonscrew

M6x25(forwall

mountingonmetal)

2hexagonscrews

M6x25(forwall

mountingonmetal)

143

45

141,5

Loading...

Loading...