permaPROMP-6Distributor -9-

351,5(forlubricatorswithPROLC250)

402,5(forlubricatorswithPROLC500)

75

45

4.3 Combination of Distributor and Lubricator

AfteryouhaveequippedthepermaMP-6withconnections,youcanconnectthedistributortoalubricatorofthe

PROrange.

Screw the distributor and the lubricator together. Attach both to the perma mounting device and install

the mounting device.

Direct Mounting of the Distributor onto the Lubricator

♦ Beforeyouconnectthedistributorandthelubricator,alllubricationpointsmustbepre-greasedandallgrease

linesmustbepre-lledwiththesamelubricantthatthePROLCunitcontains.Forthat,perma-tecoffersa

400glubricationcartridgeformanually-operatedgreasepresseswiththerequestedlubricant.

♦ ScrewthelubricatortightlyintotheG3/8threadofthedistributor.

♦ Positiontherearsidesofthelubricatorandthedistributoratonelevel.

♦ Attachthesuppliedmountingdevicetothedistributorandthelubricatorusingtheenclosedhexheadbolts

(M6x16)andthewashers.

♦ Screwthemountingdevicetogetherwiththelubricationsystemontoasupportofyoursystem.

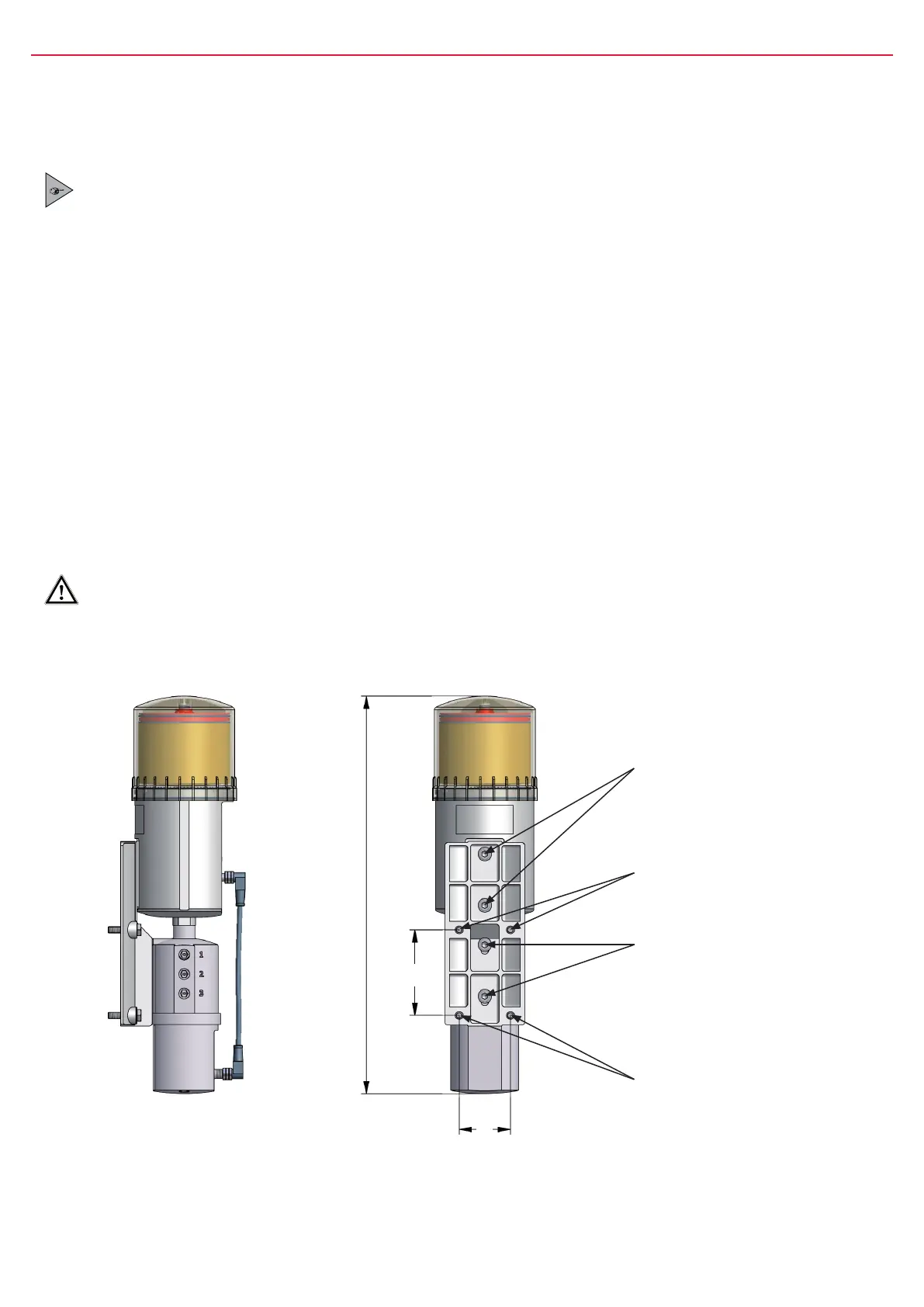

Forthepositionoftheboresofthefourxingscrewsrefertogure6below.Youhavetousefourhexagon

screwsM6x25(e.g.onmetalground).

♦ Connectthegreaselinestotheconnectionsofthedistributorandinstallthetubescorrectlybetweenthe

distributorandthelubricationpoint.Tubelengthmaynotexceedvemetersperoutlet.

♦ Attachtherequiredconnectionstotheendsofthelubricanttubes.

♦ Whilethelubricationsystemisswitched offconnectthelubricatortothedistributorwiththeconnectingcable.

♦ Thelubricationsystemisnowreadyforoperation.

Ensure correct and tight assembly of the connections and grease lines to avoid possible leakage.

gure6

2hexheadboltsM6x16,

maximumtorque3Nm

(forattachingthelubricatortothe

mountingdevice)

2hexagonscrews

M6x25(forwall

mountingonmetall)

2hexheadboltsM6x16,

maximumtorque3Nm

(forattachingthedistributorto

themountingdevice)

2hexagonscrews

M6x25(forwall

mountingonmetal)

Loading...

Loading...