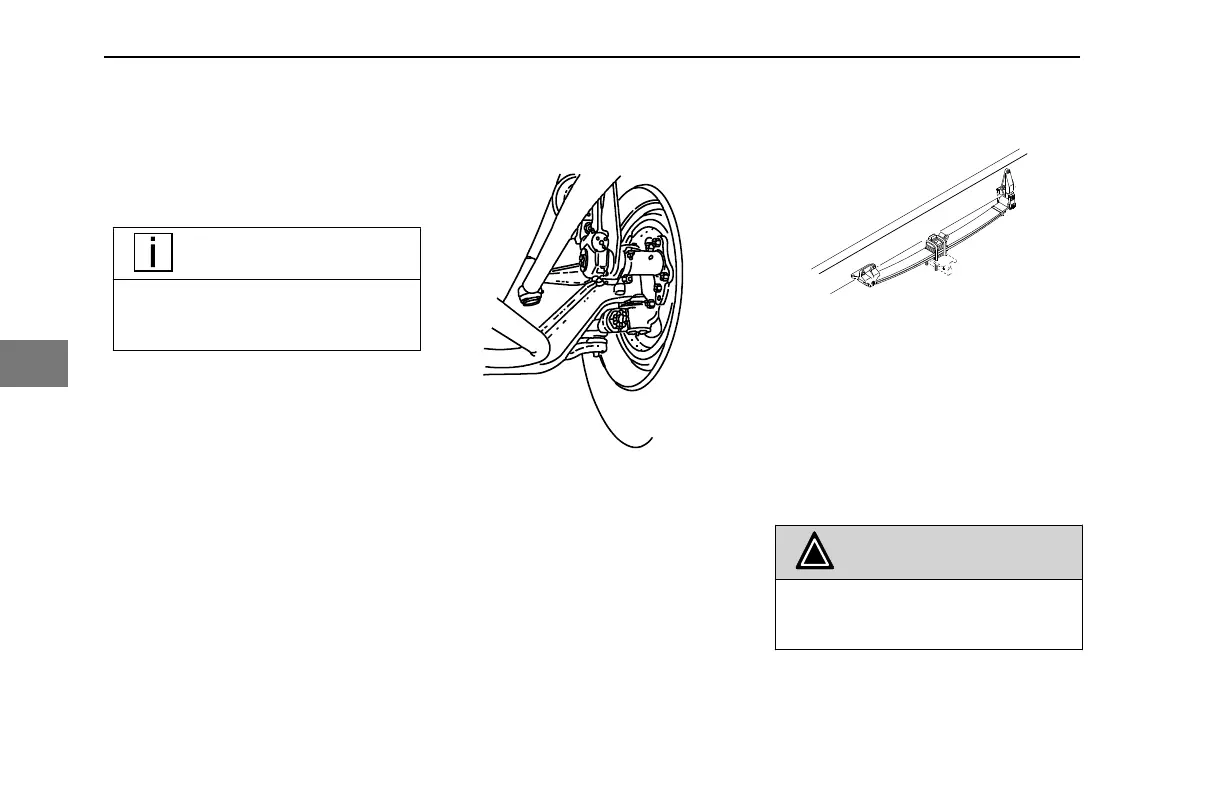

Sliding Fifth Wheels

Lubricate bearing surface of support

bracket through the grease fittings on the

side of the fifth wheel plate. Use a water

resistant lithium-base grease.

NOTE

The plate must be lifted up slightly to

relieve the weight of the bracket while

applying grease.

Front Axle and

Suspension

Axle Lubrication

Refer to the axle manufacturer's operator's

manual for lubrication specifications and

service intervals.

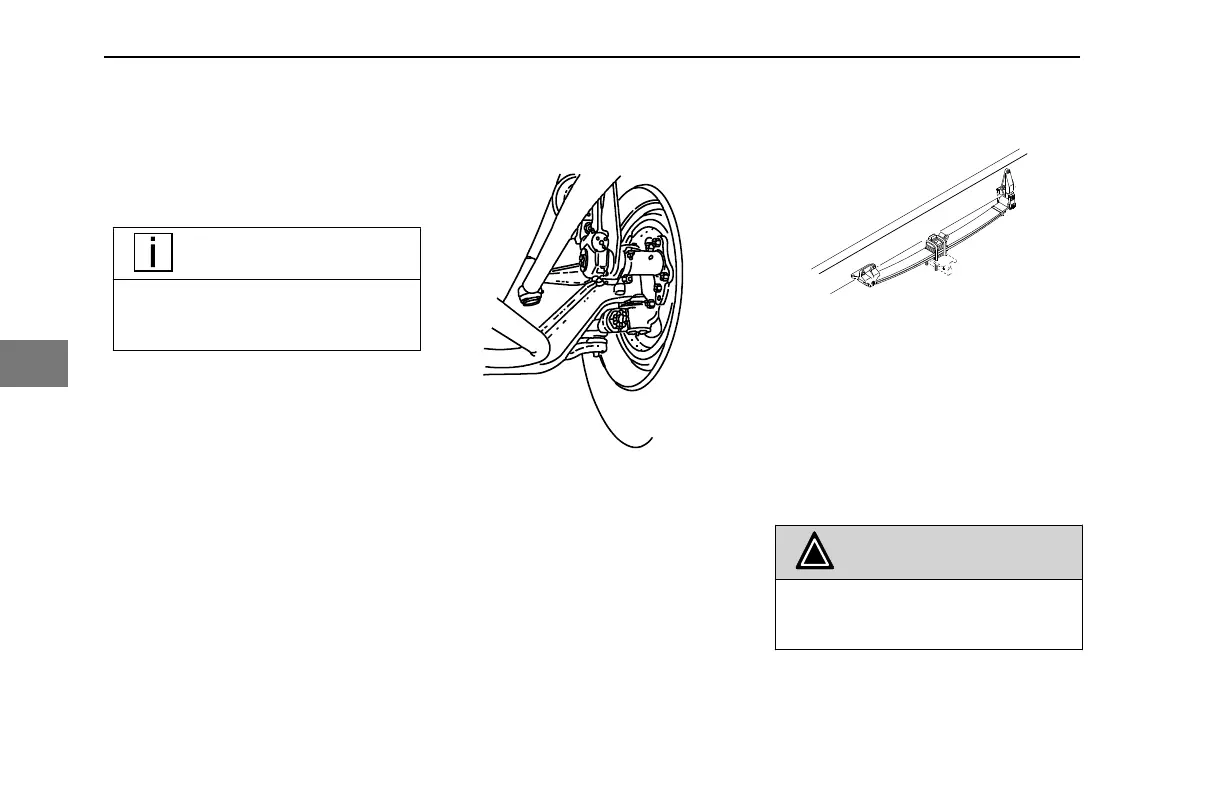

Kingpin Lubrication

Lubricate with approved lubricant.

Lubricate knuckle thrust bearings, knuckle

pins, and tie rod ends. Lack of lubrication

causes premature wear and hard steering.

Lubrication schedule may be shortened if

necessary.

Suspension Lubrication

Each standard spring anchor pin has a

grease fitting. Pressure lubricate spring

pins as specified. At regular intervals, the

spring leaves may be lubricated with a

rust-inhibiting oil applied with a spray gun

or brush. Depending on your suspension,

lubricate all spring pins until grease flows

out of both ends of the bushing. Look for

signs of rust or water in the flushed grease.

If a pin will not accept grease, it should be

removed, cleaned, and inspected.

CAUTION

DO NOT spray the suspension with

chemical products or mineral oil; it can

cause damage to the bushings.

MAINTENANCE - Front Axle and Suspension

252 Y53-6076-1D1 (09/20)

5

Loading...

Loading...