To

adjust,

loosen

screw

a on needle bar

connecting

stud,

and set needle bar

higheror

lower,

as maybe required

(Fig.

22).

(3)Setting

Needle

to Shuttle

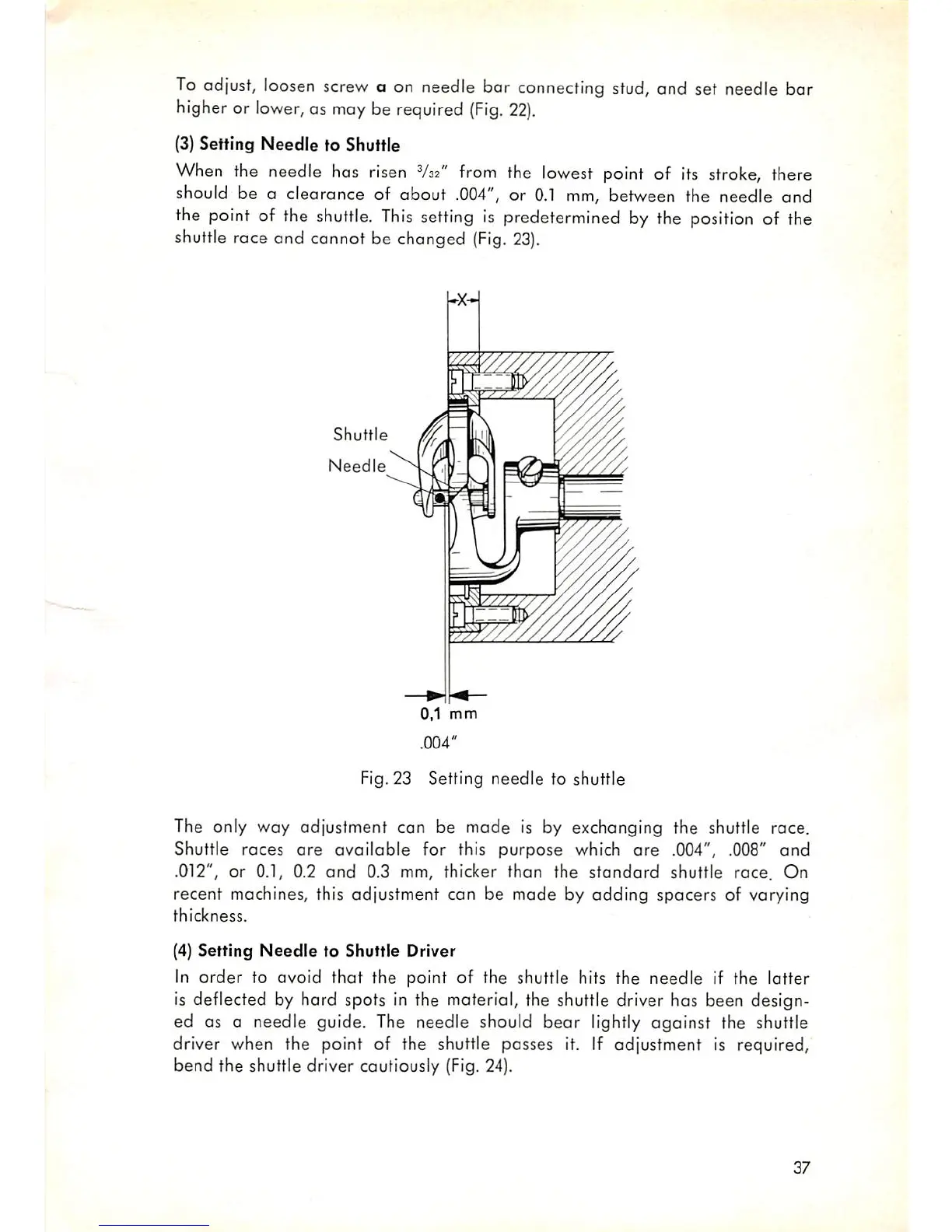

When the needle has risen

V32"

from the lowest point of its stroke, there

should be a clearance of about

.004",

or

0.1

mm,

between the needle ond

the point of the

shuttle.

This

setting

is

predetermined

by

the

position

of the

shuttle race and cannot be changed

(Fig.

23).

Shuttle

Needle

0,1

mm

Fig. 23 Setting needle to shuttle

The only way adjustment can be made is by exchanging the shuttle race.

Shuttle races

are

available

for this purpose which

ore

.004", .008"

and

.012",

or

0.1, 0.2

and

0.3 mm,

thicker

than

the

standard

shuttle

race.

On

recent machines, this adjustment

can

be

made

by

adding

spacers

of varying

thickness.

(4) Setting

Needle

to Shuttle Driver

In

order

to avoid

that

the point of the shuttle hits the

needle

if the

letter

is deflected by hard spots in the material, the shuttle driver has been design

ed as a

needle

guide. The needle should

bear

lightly

against

the shuttle

driver when the point of the shuttle passes it. If adjustment is required,

bend the shuttle driver coutiously (Fig. 24).

37

Loading...

Loading...