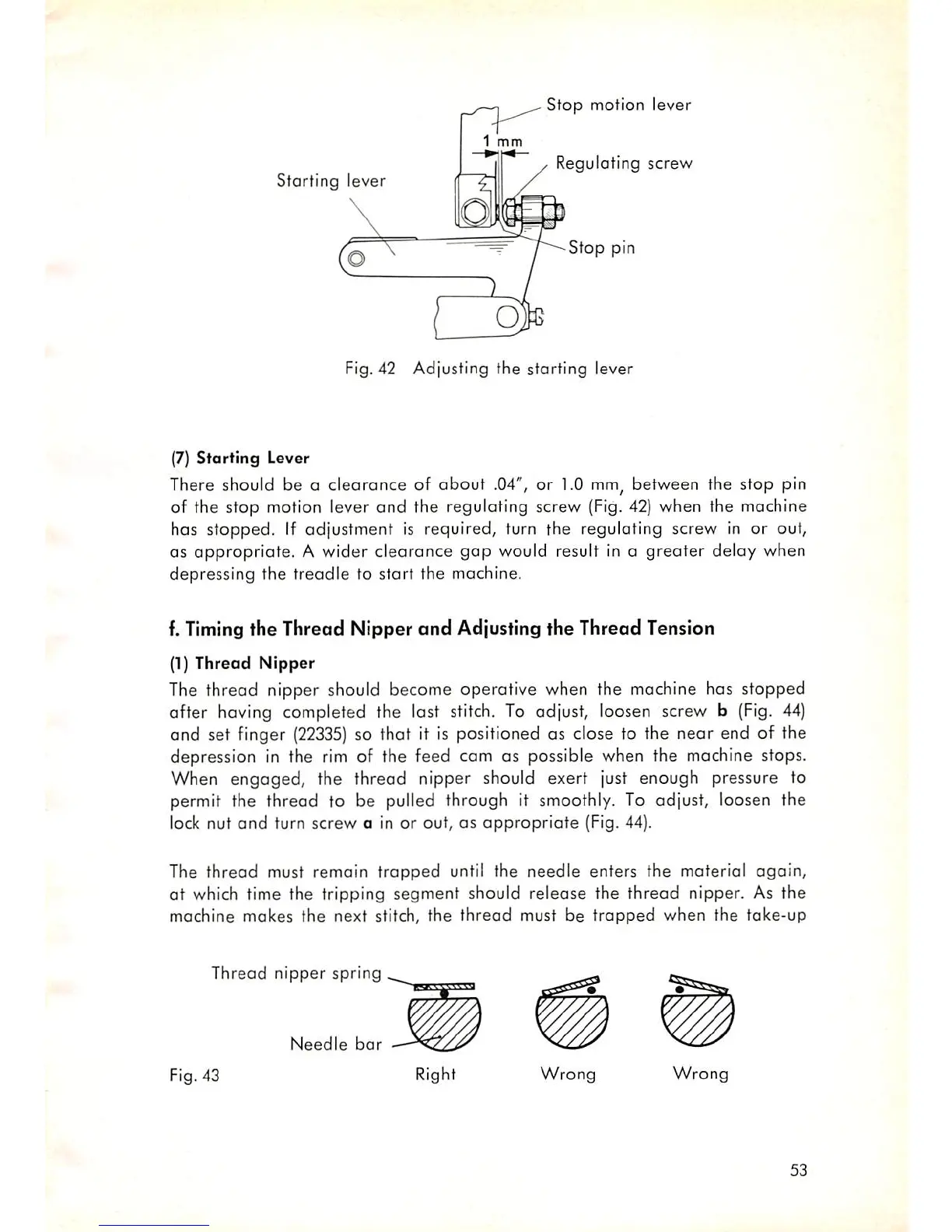

Stop

motion lever

1

mm

Starting

lever

Regulating

screw

—/^--Sfop

pin

Fig. 42 Adjusting the starting lever

(7)

Starting

Lever

There should be a clearance of about .04", or 1.0

mm,

between the stop pin

of the stop motion lever

and

the reguloting screw

{Fig.

42) when the machine

has

stopped.

If

adjustment

is required, turn the regulating screw in or out,

OS

appropriate. A wider clearance

gap

would result in a greater delay when

depressing the treadle to start the machine.

f.

Timing

the Thread Nipper

and

Adjusting the Thread Tension

(1) Thread

Nipper

The thread nipper should become operative when the machine has stopped

after having completed the last stitch. To adjust, loosen screw b (Fig. 44)

and set finger

(22335)

so that it is positioned as close to the near end of the

depression in the rim of the feed cam as possible when the machine stops.

When

engaged,

the thread nipper should exert just enough pressure to

permit the thread to be pulled through it smoothly. To adjust, loosen the

lock nut

and

turn

screw

a in or out, as

appropriate

(Fig. 44).

The

thread

must remoin

trapped

until the

needle

enters the material

again,

ot which time the tripping segment should release the thread nipper. As the

machine

makes

the

next stitch, the

thread

must be

trapped

when

the

take-up

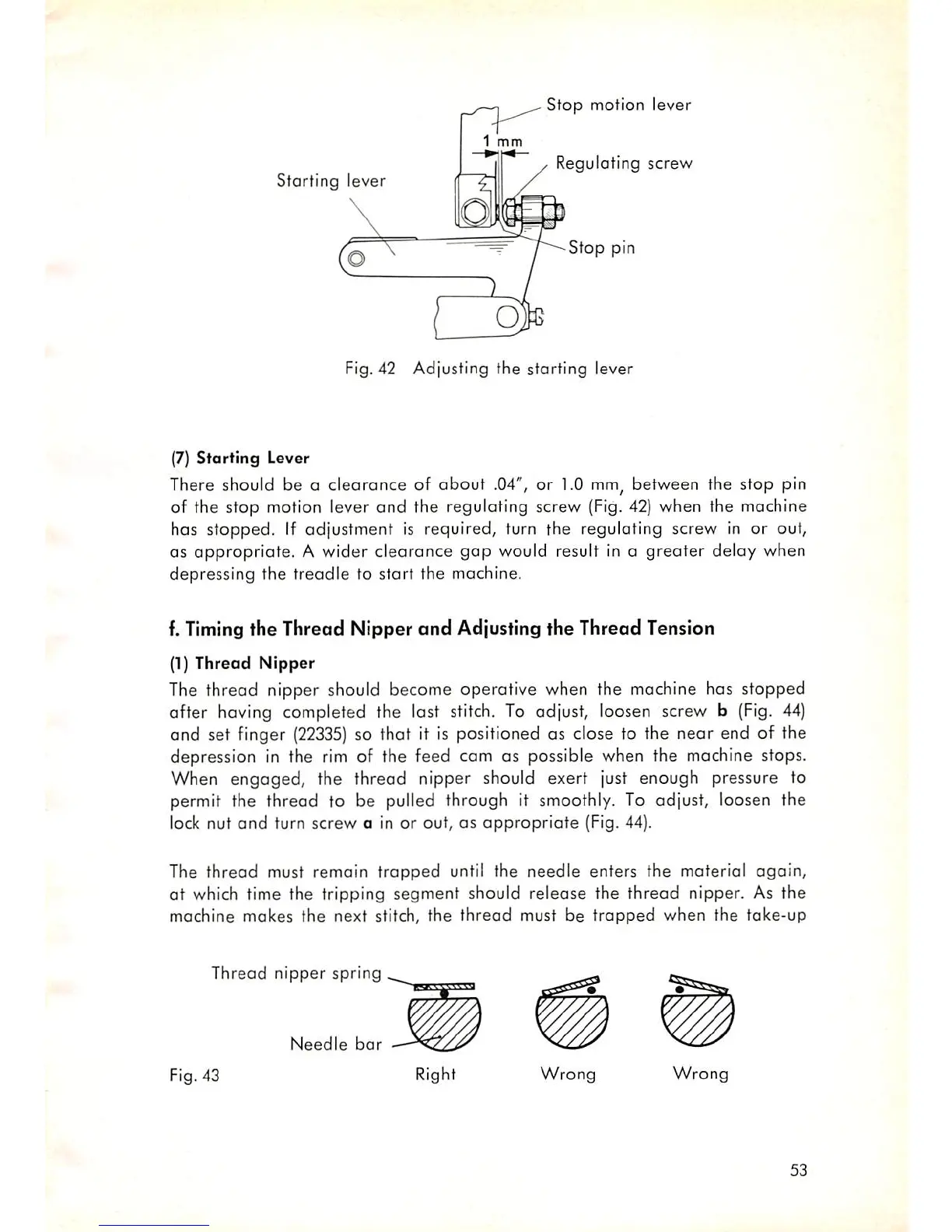

Thread nipper spring

Needle

bar

Fig. 43

Right

Wrong

Wrong

53

Loading...

Loading...