6.

Subclass

Conversion

Parts which differ with each subclass

are

compiled in the Annex. (See also

Form No. 10080, Subclass

Organizations

of the Pfaff 3334).* Such

parts

are

essentially the feed cam, the clomp feet,

and

the feed plate. If the worm

gear

assembly has to be

exchanged

in

order

to convert

one

subclass machine

into

another,

it is

advisable

to ship the machine to your

nearest

PfafF

distributor.

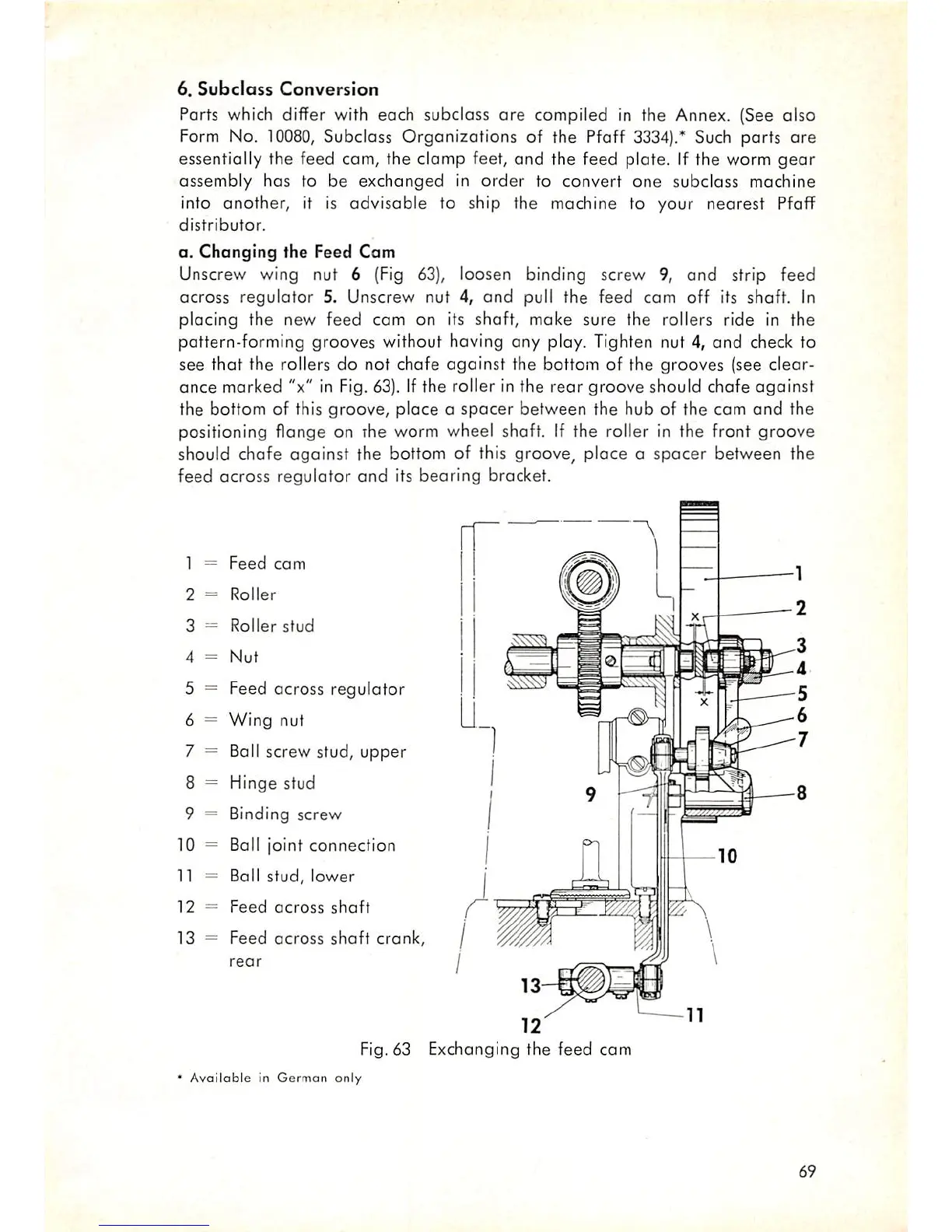

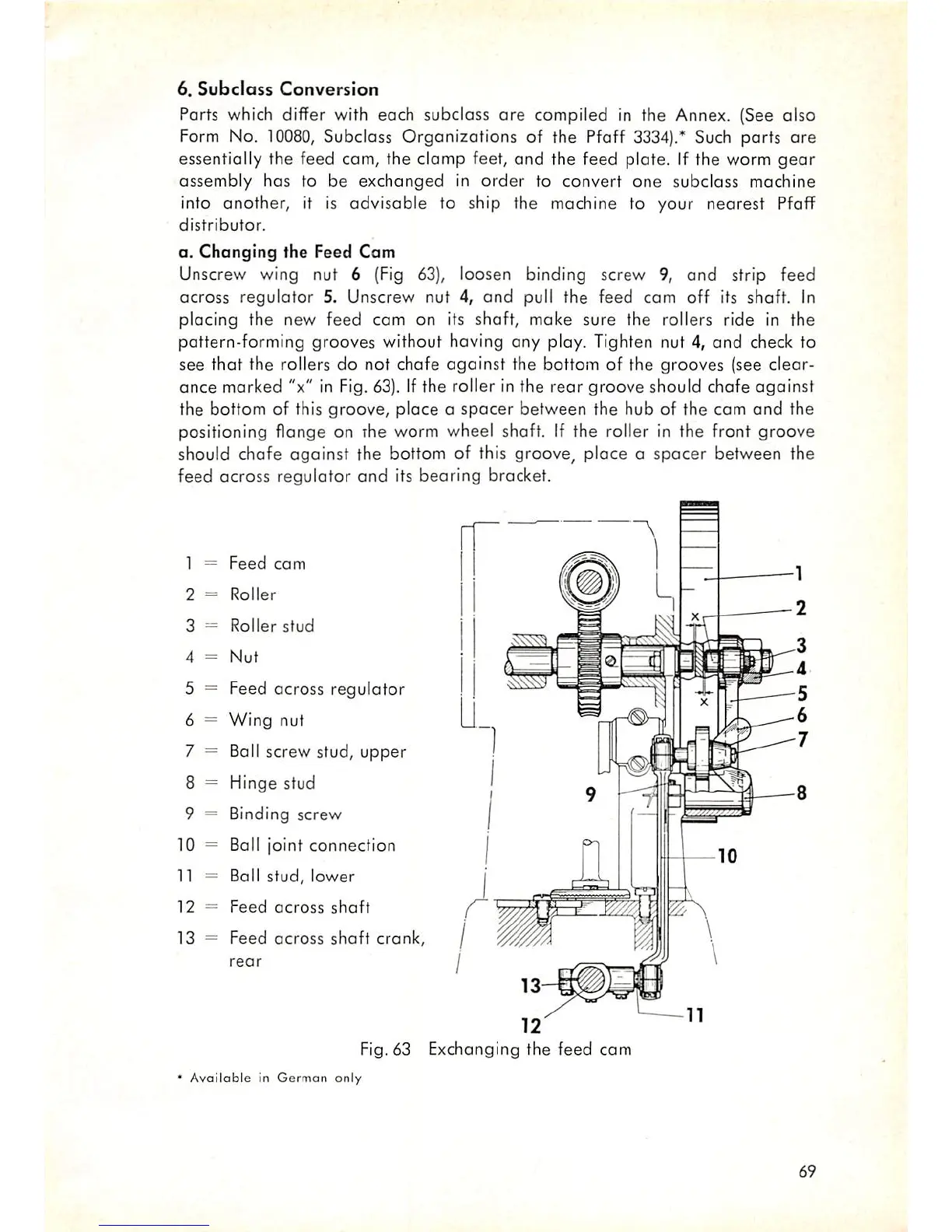

a.

Changing

the Feed Com

Unscrew wing nut 6 (Fig 63), loosen binding screw 9,

and

strip feed

across

regulator

5. Unscrew nut 4,

and

pull

the

feed

cam

off its

shaft.

In

placing the new feed com on its shaft, make sure the rollers ride in the

pattern-forming grooves without having any play. Tighten nut 4, and check to

see that the rollers do not chafe against the bottom of the grooves (see clear

ance

marked "x" in Fig. 63). If the roller in the

rear

groove

should chafe

against

the bottom of this groove, place a

spacer

between

the hub of the cam

and

the

positioning flange on the worm wheel shaft. If the roller in the front groove

should chafe ogainst the bottom of this groove, place a spocer between the

feed across regulator

and

its bearing bracket.

1 =

Feed

cam

2 =

Roller

3 =

Roller

stud

4 =

Nut

5 = Feed across regulator

6 =

Wing

nut

7 = Ball screw stud,

upper

8 = Hinge stud

9 = Binding screw

10 = Ball joint connection

11 = Boll

stud,

lower

12

=

Feed

across

shaft

13 = Feed

across

shaft

crank,

rear

Fig.63 Exchanging the feed com

Available in Germon only

L

69

Loading...

Loading...