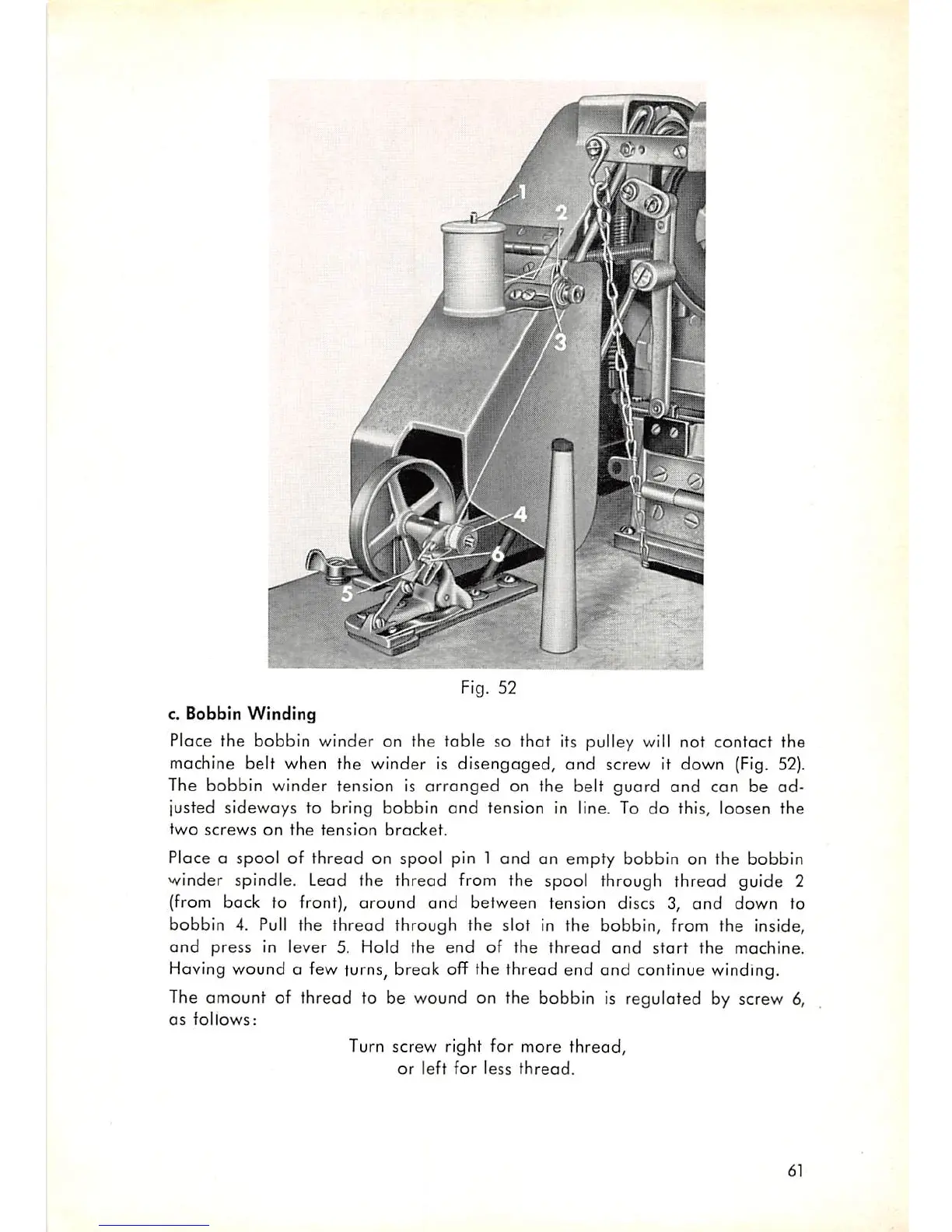

Fig. 52

c. Bobbin

Winding

Place the bobbin winder on the table so that its pulley will not contact the

machine belt when the winder is disengaged, and screw it down

(Fig.

52).

The bobbin winder tension is

arranged

on the belt guard and can be ad

justed sideways to bring bobbin

and

tension in line. To do this, loosen the

two

screws

on

the

tension

bracket.

Place a spool of

thread

on spool pin 1

and

an empty bobbin on the

bobbin

winder spindle. Lead the threod from the spool through thread guide 2

(from back to front), around and between tension discs 3,

and

down to

bobbin 4. Pull the thread through the slot in the bobbin, from the inside,

and

press in lever 5. Hold the

end

of the

thread

and

start

the machine.

Having wound a few turns, break off the thread end

and

continue winding.

The amount of thread to be wound on the bobbin is regulated by screw 6,

as

follows:

Turn screw right for more

thread,

or

left

for

less

thread.

61

Loading...

Loading...