b.

Timing

the Feed Motion

Timing

the feed motion is explained with the aid of o subclass -2 machine

because the adjustment procedures can best be demonstrated here. These

procedures apply to other subclasses accordingly.

(1}

Synchronizing the Feed Motion with the Needle Motion

The feed motion normally must not begin

until

the needle has risen clear of

the fabric, and must be completed when the needle enters the materiel

again. When extra-thick materials are being sewn, the observation of this

rule may prove impossible because the needle does not remain outside the

fabric

long

enough.

In

such

cases,

set the

machine

so that it

starts

feeding

shortly

before

the

ascending

needle

has

risen

clear

of

the

moterial

complete

ly.

Make

sure,

however,

the feed

motion

is

completed

when

the needle

point reaches the goods again. If the feed motion continues

after

the needle

has

entered

the

material

again,

needle

breakage

is

likely

to

occur.

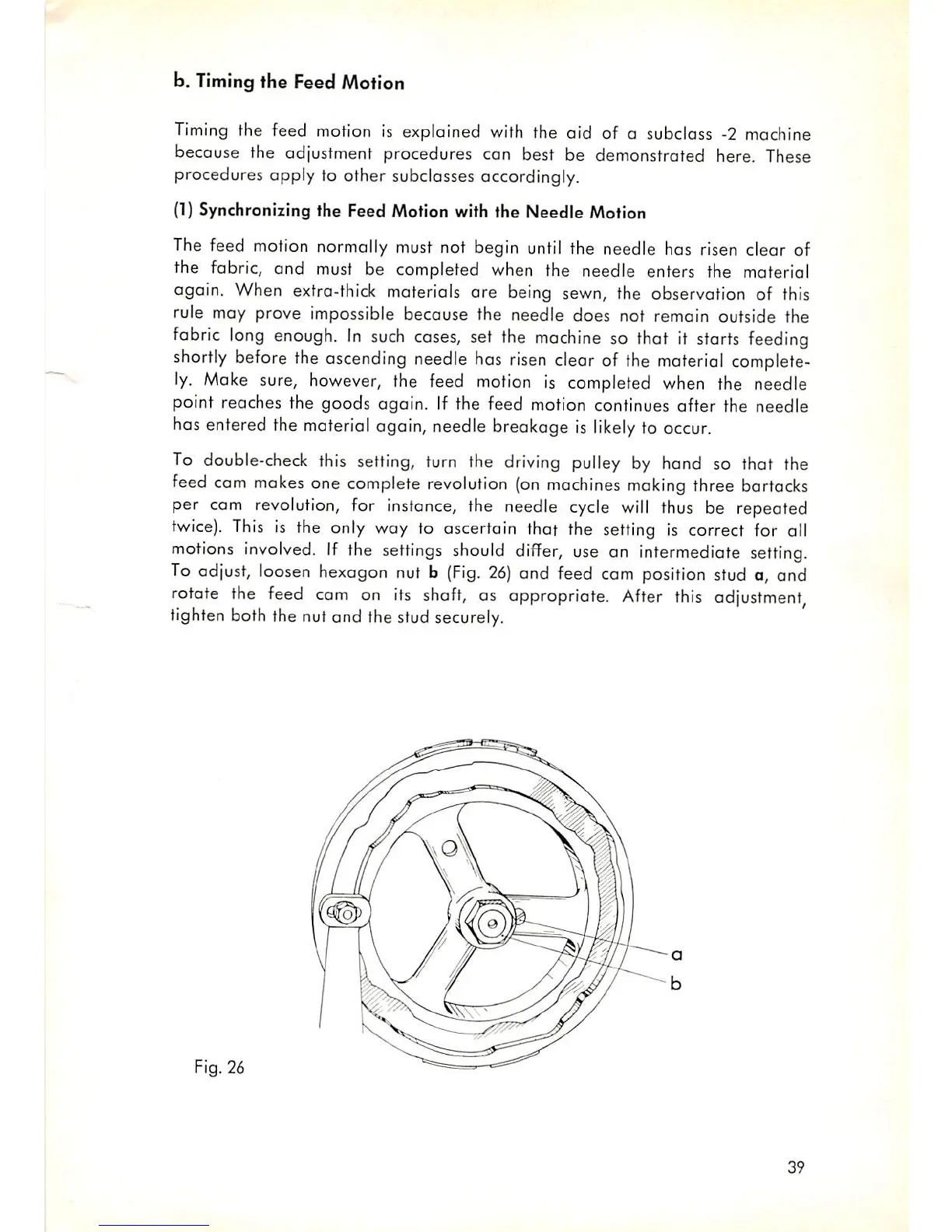

To

double-check

this setting, turn the

driving

pulley

by hond so that the

feed

cam

makes

one

complete

revolution

(on

machines

making

three

bartacks

per

com

revolution,

for

instance,

the needle

cycle

will

thus

be repeated

twice).

This

is the only way to ascertain that the

setting

is correct for all

motions

involved.

If

the

settings

should

differ,

use

an

intermediate

setting.

To adjust,

loosen

hexagon nut b

(Fig.

26)

and feed cam

position

stud a, and

rotate

the

feed

cam

on

its

shaft,

as

appropriate.

After

this

adjustment,

tighten

both the nutand the

stud

securely.

Fig. 26

39

Loading...

Loading...