8.

Machine

Core

a. Cleaning

and

Oiling

Careful cleaning and regular oiling increase the service life of the machine

and

ensure smooth running.

When

the machine is delivered to the customer, all polished

parts

are

covered

with a rust-preventative grease. Remove this grease, together with the dust

which has

accumulated

in transit,

before

you put the machine in

operation.'

Also, squirt an ample amount of oil into all marked oiling points, unthread

the needle,

take

out the bobbin case,

and

run the machine to work the oil

into all the bearings. All important oiling points

are

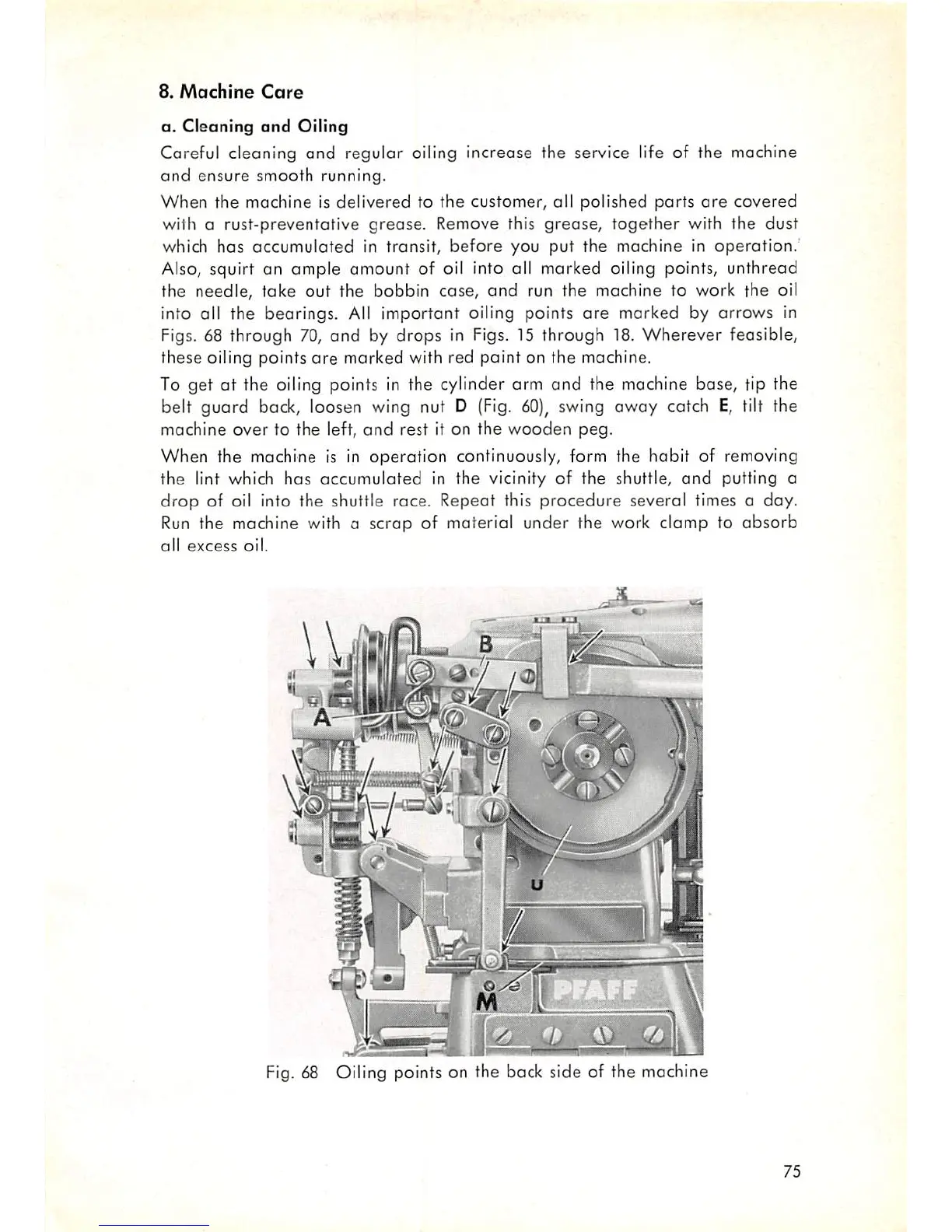

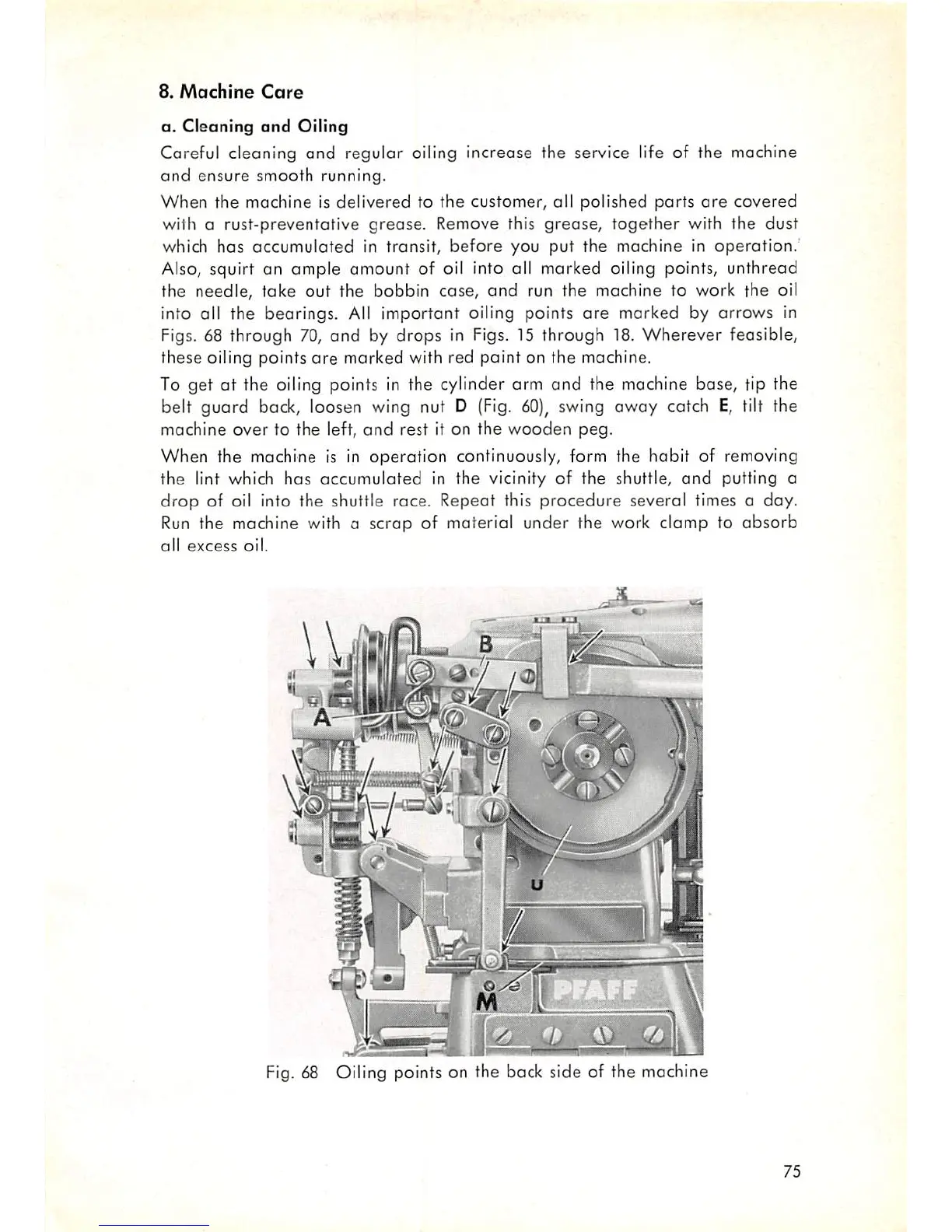

marked by arrows in

Figs. 68 through 70,

and

by drops in Figs. 15 through 18. Wherever feasible,

these oiling points

are

marked

with red

paint

on the machine.

To get at the oiling points in the cylinder arm and the machine base, tip the

belt guard bock, loosen wing nut D

(Fig.

60), swing away catch E, tilt the

machine

over

to the left,

and

rest it on the

wooden

peg.

When the machine is in operation continuously, form the habit of removing

the lint which has

accumulated

in the vicinity of the shuttle,

and

putting a

drop of oil into the shuttle race. Repeat this procedure several times a day.

Run

the mochine with a scrap of material under the work clomp to absorb

all

excess

oil.

W

I

Fig. 68 Oiling points on the back side of the machine

75

Loading...

Loading...